Workshop scheduling simulation method based on equipment failure scheduling model

A technology of equipment failure and workshop scheduling, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the high defect rate of product replacement equipment reprocessing, the high probability of equipment failure, and the waste of time for re-clamping and other issues to achieve the effect of shortening the design cycle, increasing the possibility, and reducing inventory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

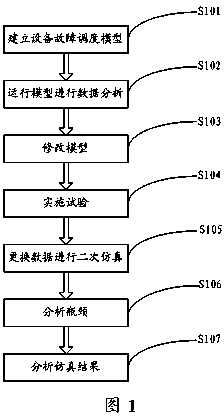

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] This method dynamically decomposes the production tasks into different levels and interconnected tasks with different granularities with logical timing by planning, task decomposition, process fusion, process optimization, etc., based on the failure of each type of equipment. Model, each production task is allocated to the most suitable equipment through equipment selection and matching, so that the workshop scheduling is dynamically formed. The logic and timing relationship between production tasks determines the relationship between equipment; the decomposition hierarchy of production tasks also determines the hier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com