Separating, acquiring and metering method and apparatus for fluid produced in thermal recovery physical simulation experiment on heavy oil

A technology for thermal recovery and fluid separation of heavy oil, applied in material inspection products and other directions, can solve the problems affecting the accuracy of physical simulation experimental data and high temperature of produced fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

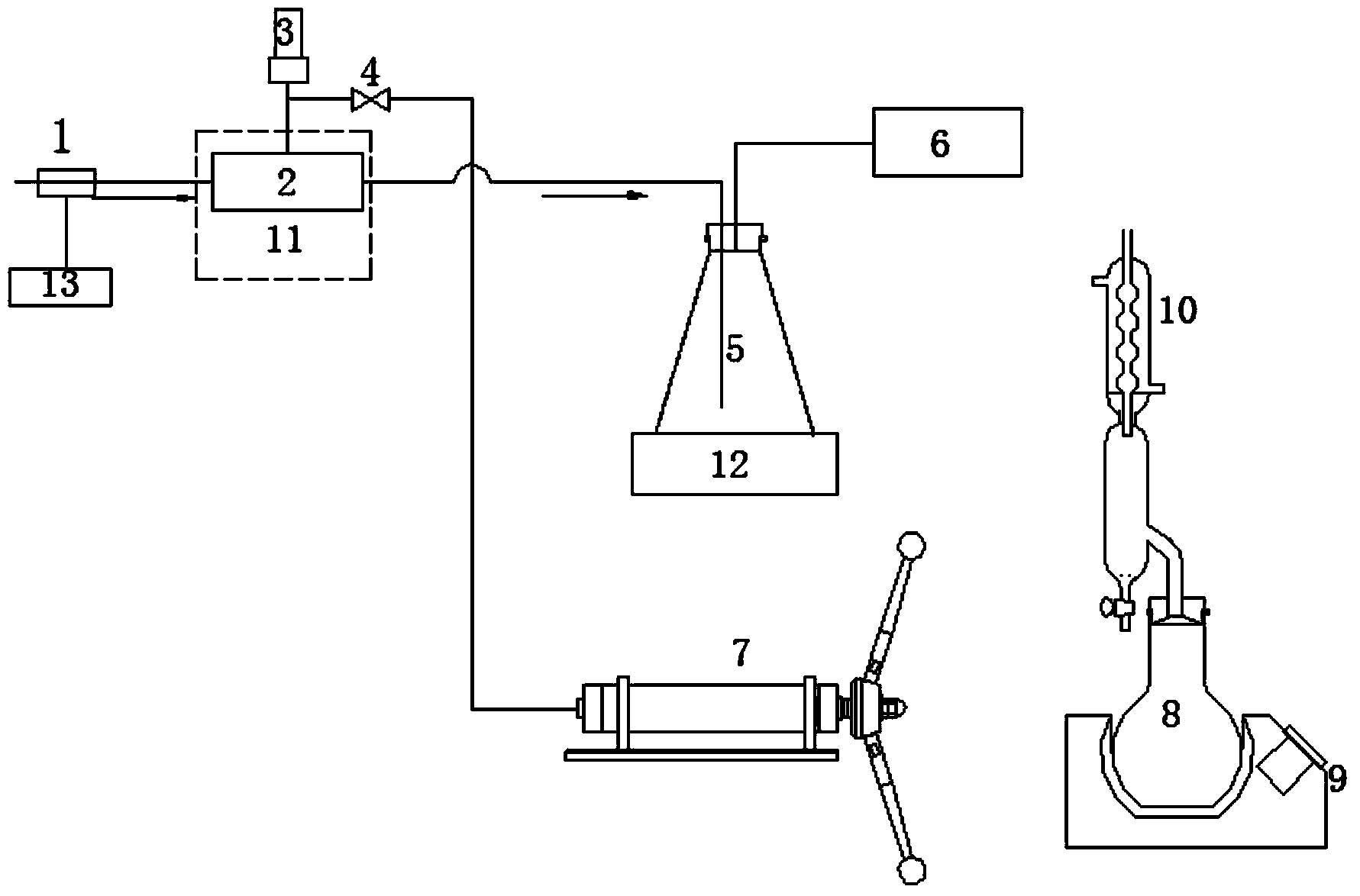

[0028] When high temperature steam (300°C) and N 2 During compound throughput experiment research, the high-temperature fluid is cooled by the cooling coil 1 controlled by the low-temperature circulating water bath 13, and enters the back pressure valve 2 in the constant temperature water bath 11. The back pressure is controlled by the manual pump 7, and the fluid is passed into the triangle with rubber plug At the bottom of the bottle 5, the gas in the triangular flask 5 enters the wet gas flow meter 6 through the separation pipeline to measure the amount of gas produced, and the balance 12 weighs the quality of the liquid in the triangular flask, and cyclohexane is added to the triangular flask with a rubber stopper in a certain proportion. After dissolving and extracting the crude oil in the oil-water mixture in the bottle 5, separate the water through the separating funnel, and measure the amount of water, and finally put the liquid after separating the water into the round...

Embodiment 2

[0031] When high temperature steam (300°C) and CO 2 and N 2 During compound throughput experiment research, the high-temperature fluid is cooled by the cooling coil 1 controlled by the low-temperature circulating water bath 13, and enters the back pressure valve 2 in the constant temperature water bath 11. The back pressure is controlled by the manual pump 7, and the fluid is passed into the triangle with rubber plug At the bottom of the bottle 5, the gas in the triangular flask 5 enters the wet gas flow meter 6 through the separation pipeline to measure the amount of gas produced, and the balance 12 weighs the quality of the liquid in the triangular flask, and cyclohexane is added to the triangular flask with a rubber stopper in a certain proportion. After dissolving and extracting the crude oil in the oil-water mixture in the bottle 5, separate the water through the separating funnel, and measure the amount of water, and finally put the liquid after separating the water into...

Embodiment 3

[0034] When high temperature steam (300°C) and N 2 +CO 2 + During the experimental study of surfactant compound throughput, the high-temperature fluid is cooled by the cooling coil 1 controlled by the low-temperature circulating water bath 13, and then enters the back pressure valve 2 in the constant temperature water bath 11, and the back pressure is controlled by the manual pump 7, and the fluid is passed into the The bottom of the triangle flask 5 with a rubber stopper, the gas in the triangle flask 5 enters the wet gas flow meter 6 through the separation pipeline to measure the amount of gas produced, the balance 12 weighs the quality of the liquid in the triangle flask, and cyclohexane is added in a certain proportion After dissolving and extracting the crude oil in the oil-water mixture in the triangle flask 5 with a rubber stopper, the water is separated through a separatory funnel, and the amount of water is measured, and finally the liquid separated from the water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com