Portable full automatic resistance spot welding ultrasonic detecting instrument and detecting method

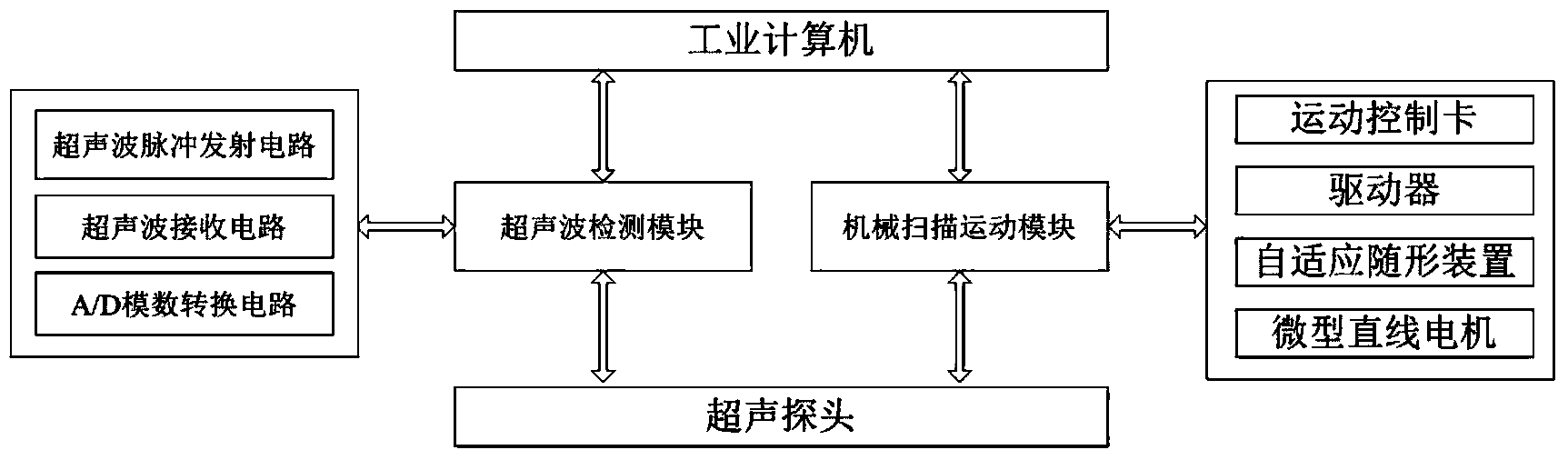

A technology of resistance spot welding and ultrasonic, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of no ultrasonic non-destructive testing equipment, lack of automation, intelligence, quantification, and difficulty in meeting industrial production. Lightweight, cost-effective, good contact coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In this embodiment, the schematic diagram of the scanning path of the ultrasonic probe to the spot welding joint is as follows: Figure 4 shown;

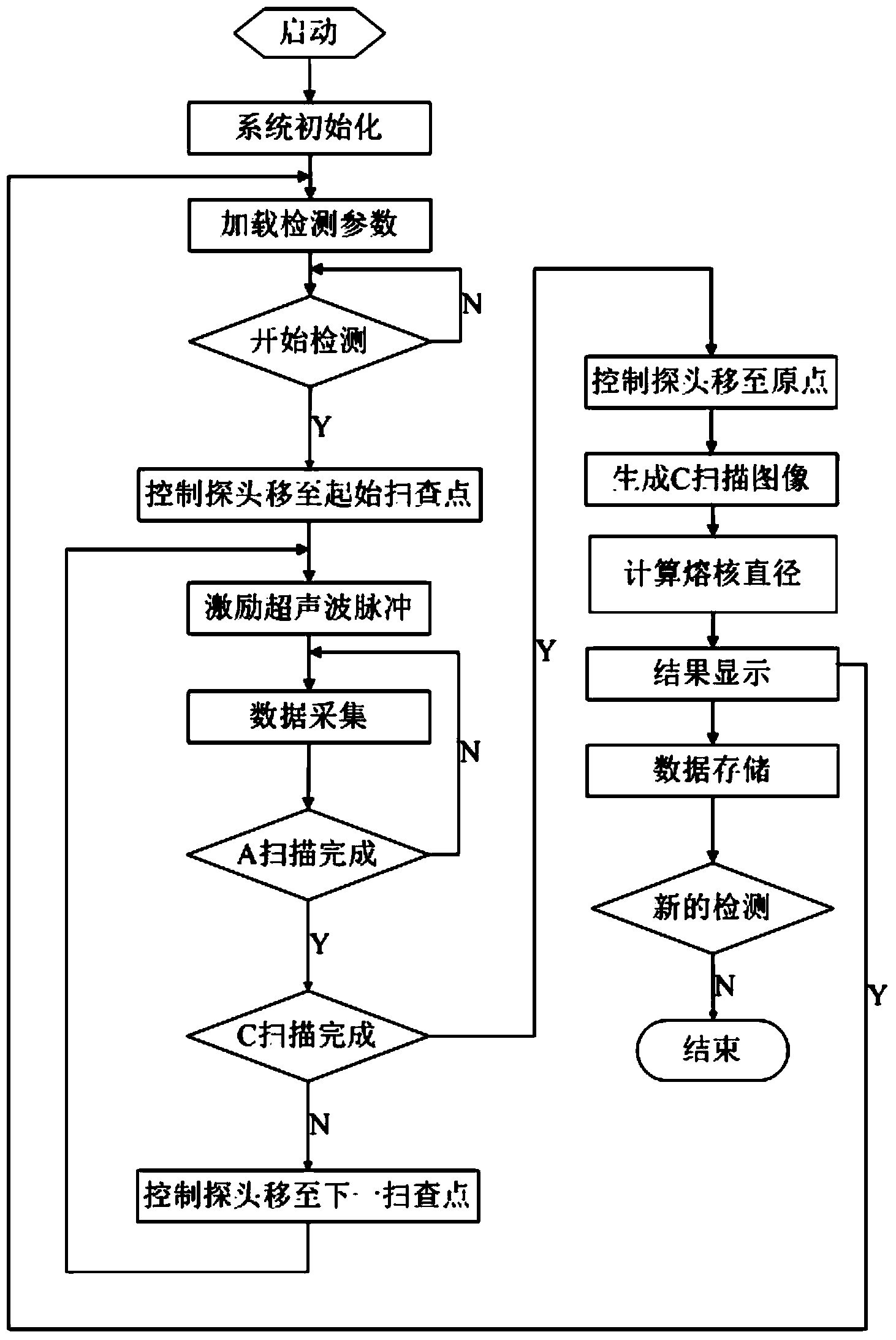

[0036] The present invention carries out the method for ultrasonic detection to the spot welding joint quality and comprises the following steps:

[0037] Step 1: After the detector is started, first load the system settings such as ultrasonic probe parameters, scanning parameters, and signal preprocessing parameters. After receiving the start detection command, move the probe to the center of the spot welding spot through the motion control module as the initial scan point. Determine the size of the rectangular scanning area according to the specific spot welding process conditions to ensure that the scanning area size is larger than the spot welding spot size. In this embodiment, the stainless steel spot welding with a plate thickness combination of 2+2mm is selected as the sample to be tested, and the rectangular plane T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com