Elastic redirection shell ejection mechanism

A kind of elastic, cartridge case technology, applied in grapple hooks, weapon accessories, offensive equipment, etc., can solve the problems of high temperature explosion, inability to push out the cartridge case completely, gunpowder smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

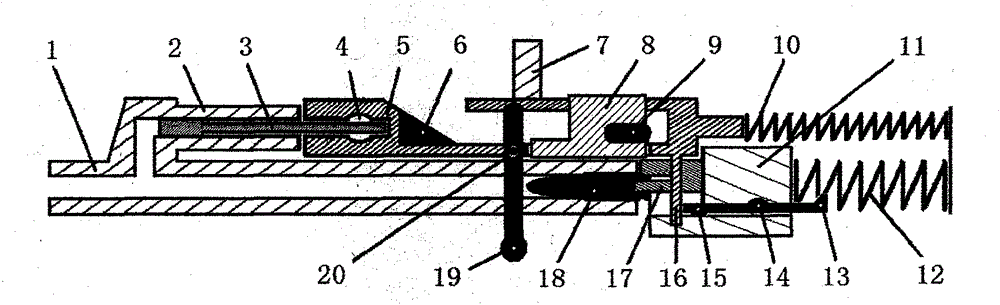

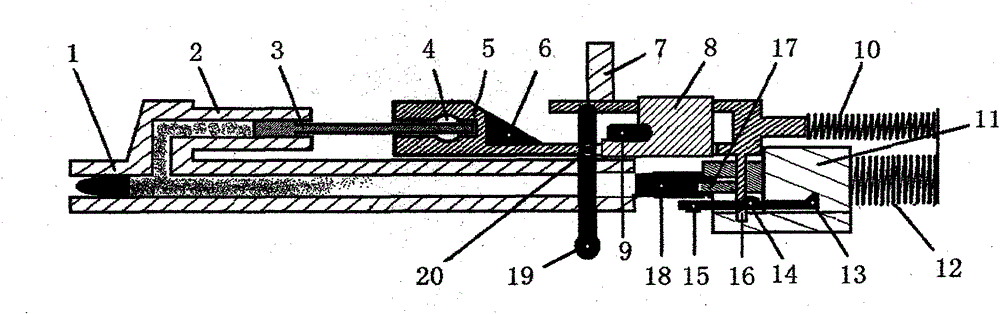

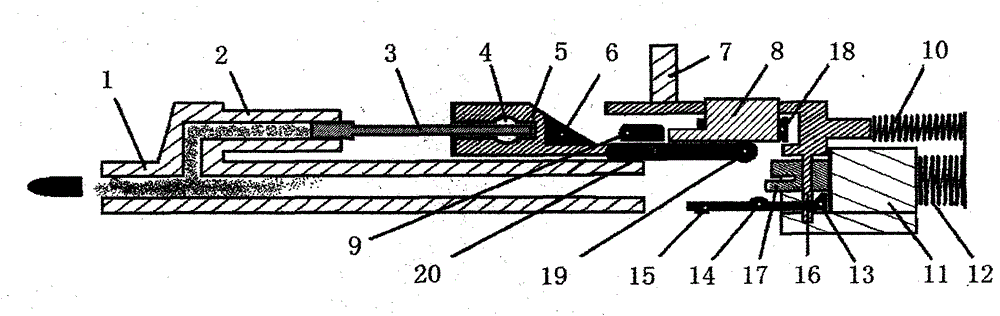

[0021] When the trigger handle is pulled by hand or the gas in the air duct is pushed, the piston rod and the ejection cylinder withstand the bolt and move back, while the ejection cylinder is exposed to the shell inlet.

[0022] The plate-shaped shell grabbing hooks installed symmetrically on both sides of the bolt pull out the shell casings. After the U-shaped lever meets the lever resistance iron, the shell end of the U-shaped lever is turned upwards, and the shell casings are pushed into the shell inlet of the ejection barrel. The bolt goes over After the trigger controls the sear, continue to retreat until the bolt is triggered and the bolt is locked. The shell ejection barrel starts to reset and eject the shell under the action of the return spring. state. After the ejection cylinder stops, the cartridge case moves forward according to inertia, and is ejected sideways after encountering an inclined plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com