Thrust bearing pack for automatically regulating axial load of turbodrill

An axial load, turbo drilling tool technology, applied in the direction of rotating bearings, shafts and bearings, sliding contact bearings, etc., can solve the problems of short life, short life and increased cost of thrust bearing sets, and achieve convenient maintenance and installation. , the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

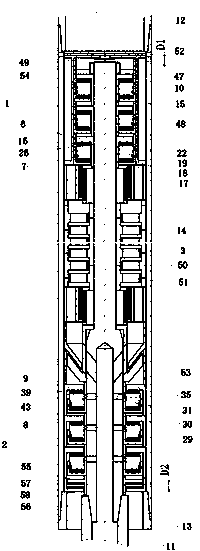

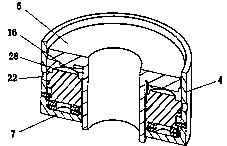

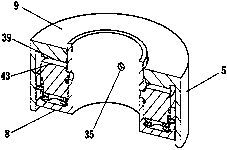

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention is a thrust bearing group that automatically adjusts the axial load of a turbodrilling tool. It is composed of an upper bearing group 1 and a lower bearing group 2. at the bottom of the turbine shaft 3. The upper bearing group 1 is composed of 3 to 5 pairs of upper bearings 4, and the upper bearing 4 is composed of an upper bearing moving ring 6 and an upper bearing static ring 7; the lower bearing group 2 is composed of 3 to 5 pairs of lower bearings 5, and the lower The bearing 5 is composed of the lower bearing moving ring 8 and the lower bearing static ring 9; the shaft head lock nut 10, the output joint 11 and the turbine shaft 3 are threadedly connected, and the upper bearing moving ring 6 and the lower bearing moving ring 8 are press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com