Method for producing aerated concrete block from iron tailings

A kind of technology of aerated concrete and iron tailings, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as hidden dangers, dangerous environment and safety of tailings dam dam failure, coarse particle size, etc. To achieve the effect of improving the composition, reducing the particle size of tailings, and increasing the content of silicon and aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

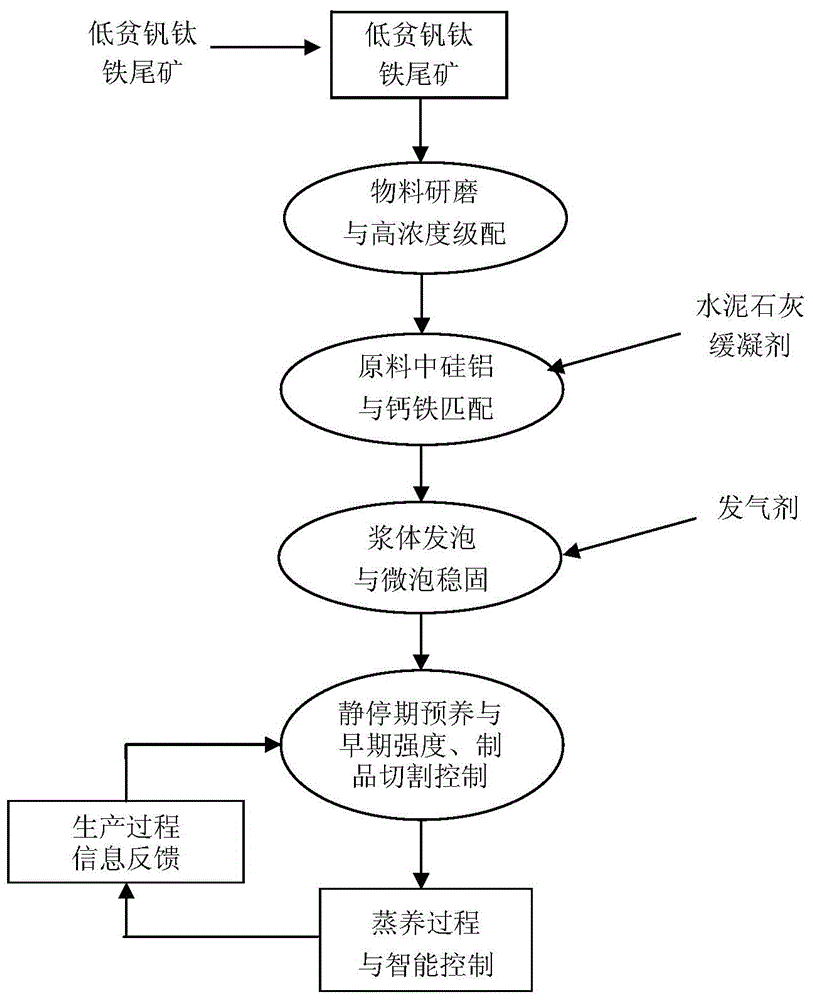

[0043] A method for producing an aerated concrete block from iron tailings, comprising the steps of:

[0044] 1) Desliming the low-vanadium-titanium ferro-titanium tailings in advance, and then grinding to obtain a powder with a particle size of less than 0.080mm;

[0045] 2) mixing the powder obtained in step 1) with cement and lime to obtain a mixture, wherein 52wt% of the powder, 25wt% of cement, and 23wt% of lime;

[0046] 3) After mixing the mixture obtained in step 2) with water, add a retarder and an air-generating agent to form a green body; the ratio of water to the mixture is 0.5; The total amount of is benchmark, and described retarder is 4.5wt%, and gas generating agent is 0.15wt%;

[0047] 4) The green body obtained in step 3) is subjected to static precuring for 2 hours, turning over and cutting, and autoclaving at 200° C. and 0.7 MPa for 7 hours to obtain the aerated concrete block.

Embodiment 2

[0049] A method for producing an aerated concrete block from iron tailings, comprising the steps of:

[0050] 1) Desliming the low-vanadium-titanium ferro-titanium tailings in advance, and then grinding to obtain a powder with a particle size of less than 0.015mm;

[0051] 2) mixing the powder obtained in step 1) with cement and lime to obtain a mixture, wherein the powder is 78wt%, cement 5wt%, and lime 17wt%;

[0052] 3) After mixing the mixture obtained in step 2) with water, add a retarder and an air-generating agent and inject and foam it into a green body; the ratio of water to the mixture is 0.8; The total amount is a benchmark, and the retarder is 0.5wt%, and the gas generating agent is 0.05wt%;

[0053] 4) The green body obtained in step 3) is subjected to static precuring for 4 hours, turned over and cut, and autoclaved at 150° C. and 2.0 MPa for 10 hours to obtain the aerated concrete block.

Embodiment 3

[0055] A method for producing an aerated concrete block from iron tailings, comprising the steps of:

[0056] 1) Desliming the low-vanadium-titanium ferro-titanium tailings in advance, and then grinding to obtain a powder with a particle size of less than 0.20mm;

[0057] 2) mixing the powder obtained in step 1) with cement and lime to obtain a mixture, wherein 65wt% of powder, 10wt% of cement, and 25wt% of lime;

[0058] 3) After mixing the mixture obtained in step 2) with water, add a retarder and an air-generating agent to form a green body; the ratio of water to the mixture is 0.64; The total amount of is a benchmark, and the retarder is 2wt%, and the gas generating agent is 0.8wt%;

[0059] 4) The green body obtained in step 3) was subjected to static precuring for 1.5 hours, turned over and cut, and autoclaved at 190° C. and 1.0 MPa for 9 hours to obtain the aerated concrete block.

[0060] According to GB11968-2006, the properties of the air-entrained concrete blocks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com