Uses of lubricating oil compositions

A technology of lubricating oil composition and use, applied in the field of lubricating oil composition, to achieve the effect of good rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

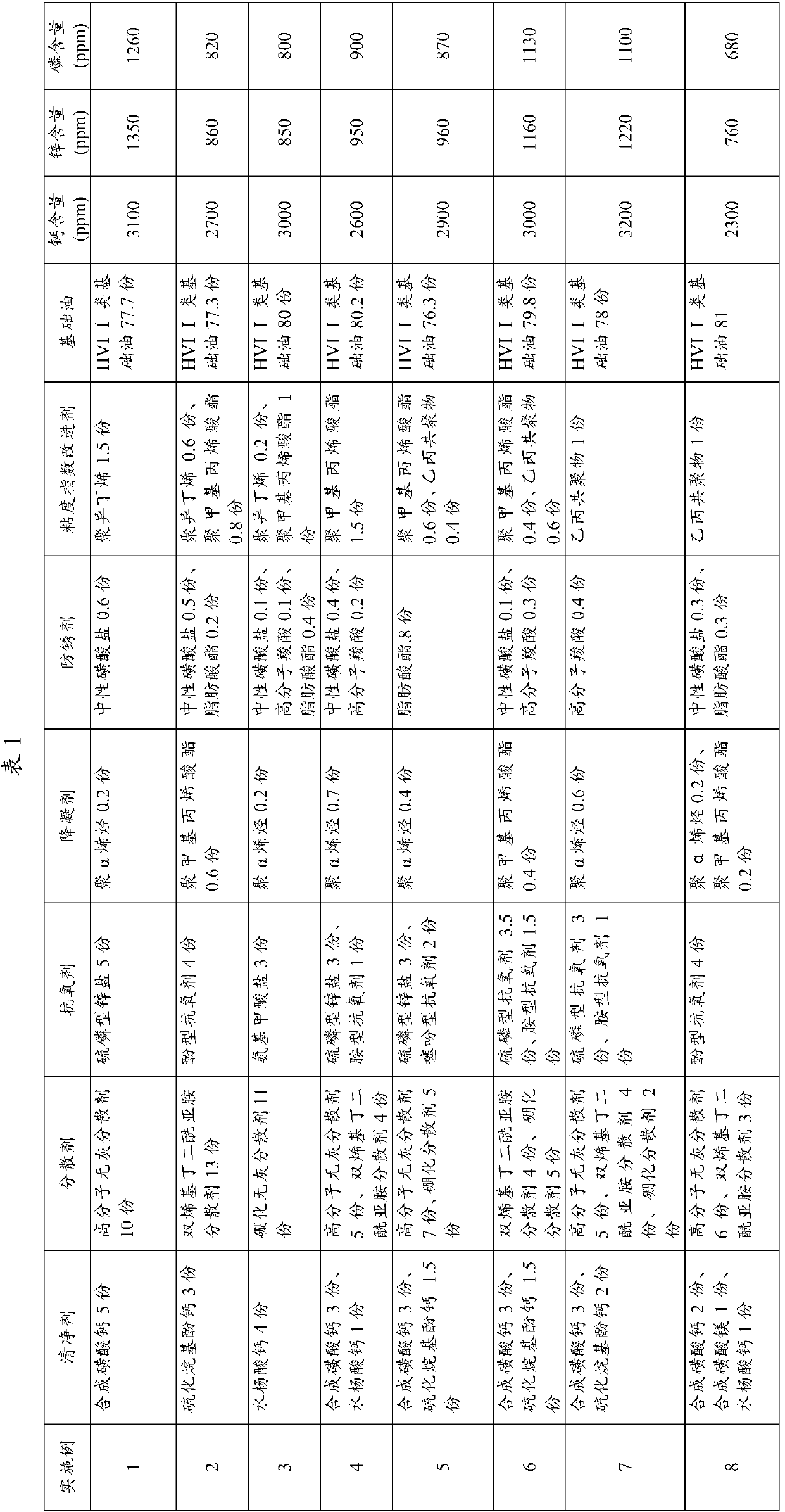

[0037] Using detergent, dispersant, antioxidant, pour point depressant, antirust agent, viscosity index improver, and HVI base oil as raw materials to prepare various formulations of dual-purpose oil for lubrication and antirust of oil-containing bearings, the composition of each formulation is shown in the table 1. The above mixture was heated and stirred at a temperature of 50-60° C. for 1 hour until completely homogeneous.

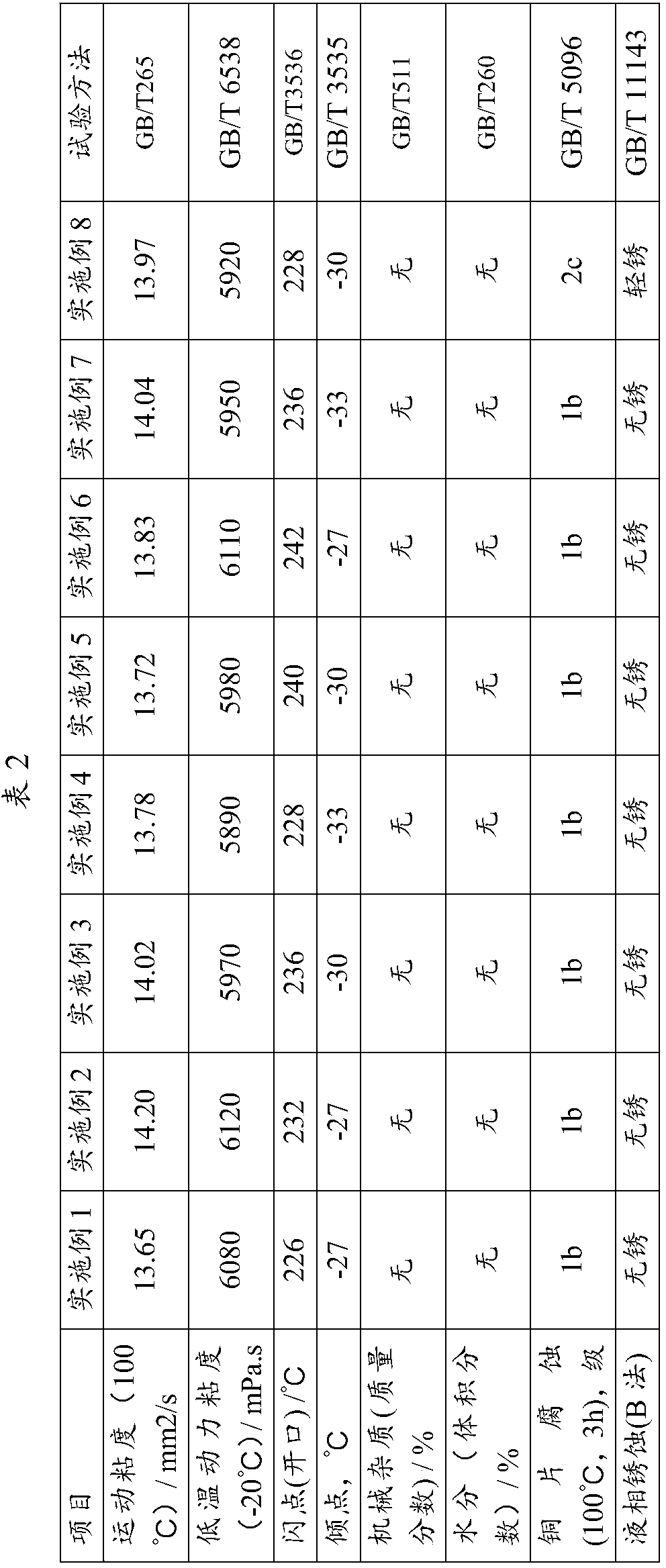

[0038] The following tests are used to investigate the performance of oil products: kinematic viscosity (100°C) indicates the internal friction of the oil when it flows at 100°C, and represents the viscosity of the oil, the higher the value, the greater the viscosity; the low temperature dynamic viscosity (-20°C) indicates the oil The internal friction of the product at -20°C indicates the cold start performance of the oil at low temperature. The lower the value, the better the cold start performance; The safety index of the product, the higher the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com