CF-4 grade diesel engine oil composition and application thereof

An oil composition, CF-4 technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of not meeting the requirements of engine oil, and achieve the effect of good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0037] Various formulations of CF-415W-40 were prepared by using detergent, dispersant, antioxidant, thickener, pour point depressant, antifoaming agent, and HVI base oil as raw materials. The composition of each formulation is shown in Table 1. The above mixture was heated and stirred at 55°C for 1 hour until completely homogeneous.

[0038] The following simulation tests were used to investigate the performance of the oil product: the oxidation induction period was used to examine the oxidation resistance of the oil product, the longer the time, the better the anti-oxidation performance of the oil product; The smaller the oil, the better the anti-wear performance of the oil; the coke plate test examines the cleanliness of the oil, the less the coke weight, the better the cleanliness of the oil; the soot dispersibility test examines the dispersibility of the oil, and the viscosity increases The smaller the ratio, the better the oil dispersion.

[0039] The specific results o...

Embodiment 8

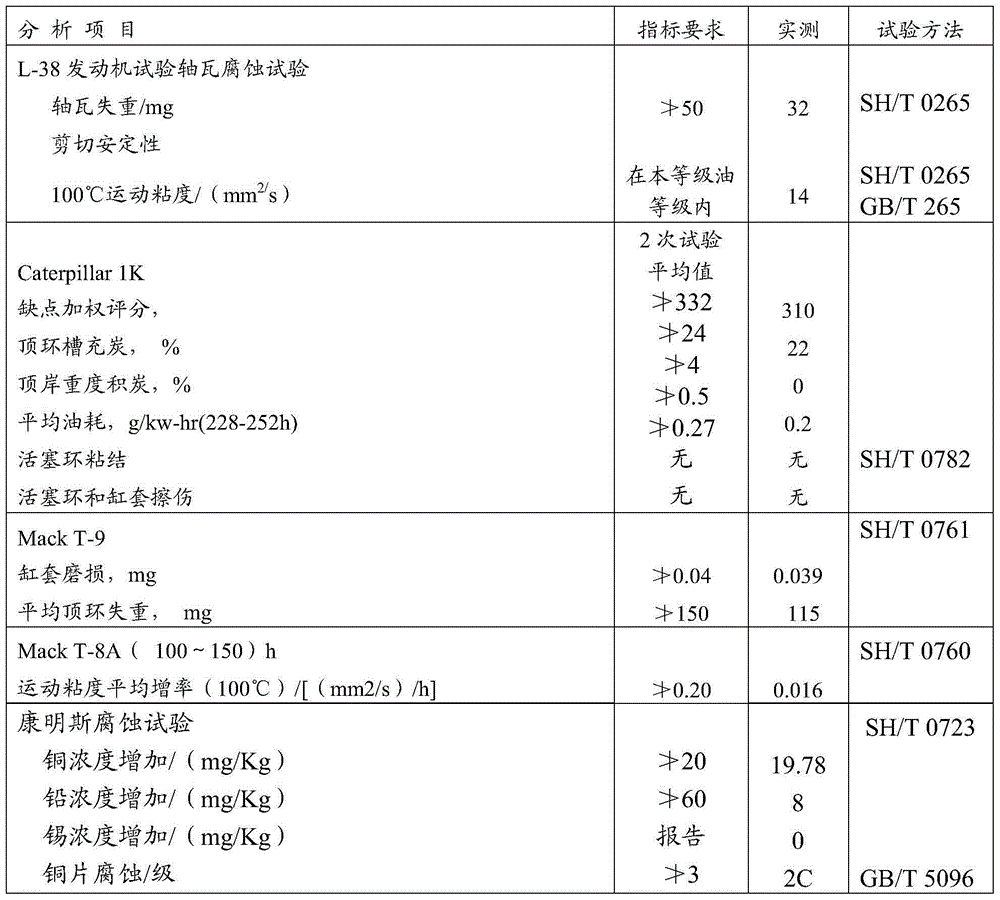

[0041] The formula described in [Example 7] was subjected to each bench test specified in GB11122-2006CF-4 quality level, and the bench test results are shown in Table 3.

[0042] Table 1 Table 2

[0043] table 3

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com