Method for preparing nano-titanium dioxide photocatalysis transparent glass coating by electrospinning technology

A technology of nano-titanium dioxide and electrospinning technology is applied in the field of manufacturing self-cleaning transparent glass coatings, which can solve the problems of high equipment investment, impossible to put into use in a large area, and complicated preparation process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

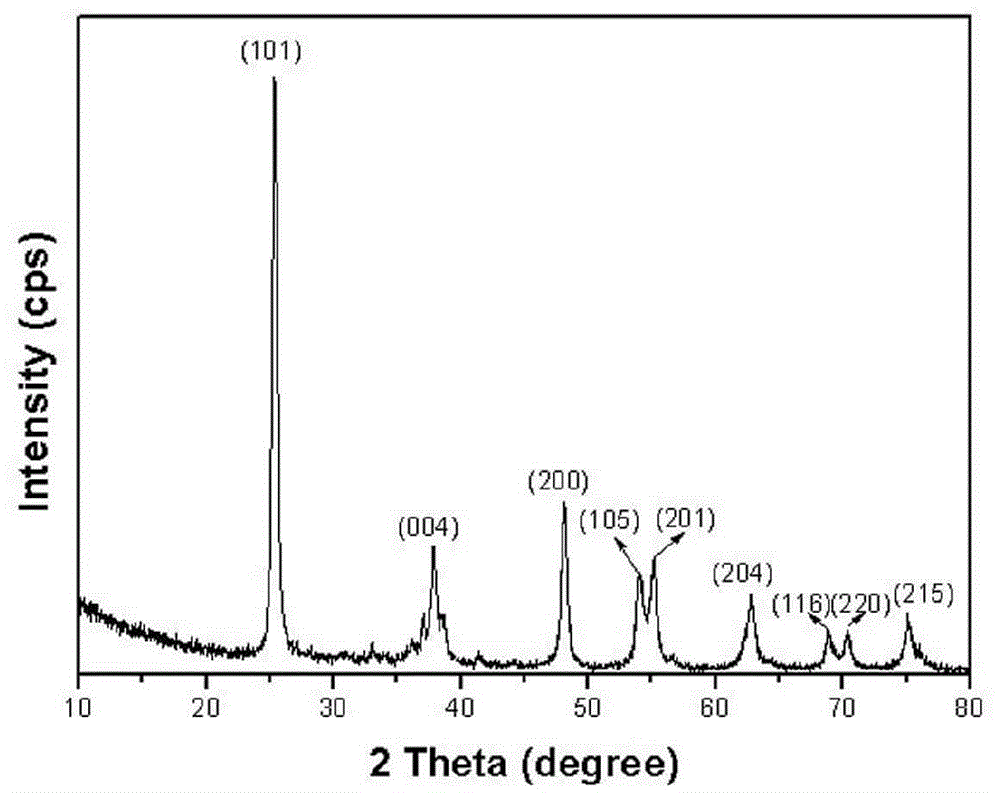

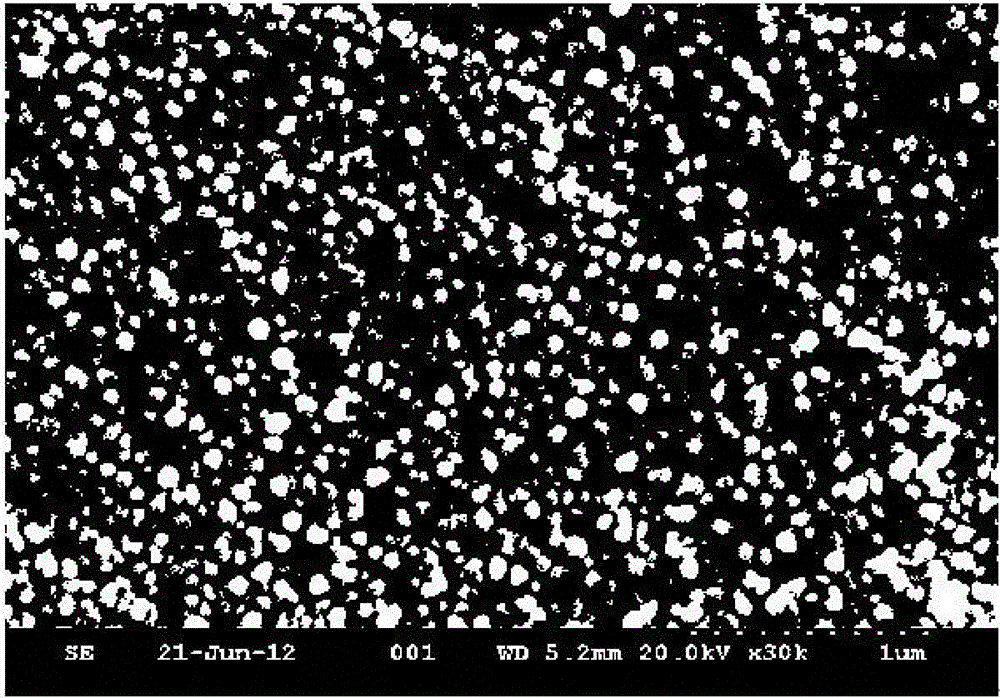

[0033] Prepare a precursor solution containing 0.0wt% DEA, and then use this solution to prepare TiO by electrospinning 2 Glass coating. The specific steps are as follows: First, take 4.0g tetrabutyl titanate, 10.0g acetic acid and 8.0g ethanol in a closed container and stir for about 30min to obtain the first homogeneous sol; in addition, take 1.6g PVP and slowly add 4.0g DMF and 12.0g ethanol solution Stir continuously in the middle for more than 12h until the PVP is completely dissolved to obtain the second sol; mix and stir the above two sols evenly to obtain the precursor solution for electrospinning. Ordinary glass slides were placed in deionized water, acetone, ethanol and isopropanol in sequence and ultrasonically cleaned, and placed at 80 o C is dried for later use. The flat collection device directly below the electrospinning nozzle is wrapped with aluminum foil, and the clean glass substrate is placed on the flat collection device. The distance between t...

Embodiment 2

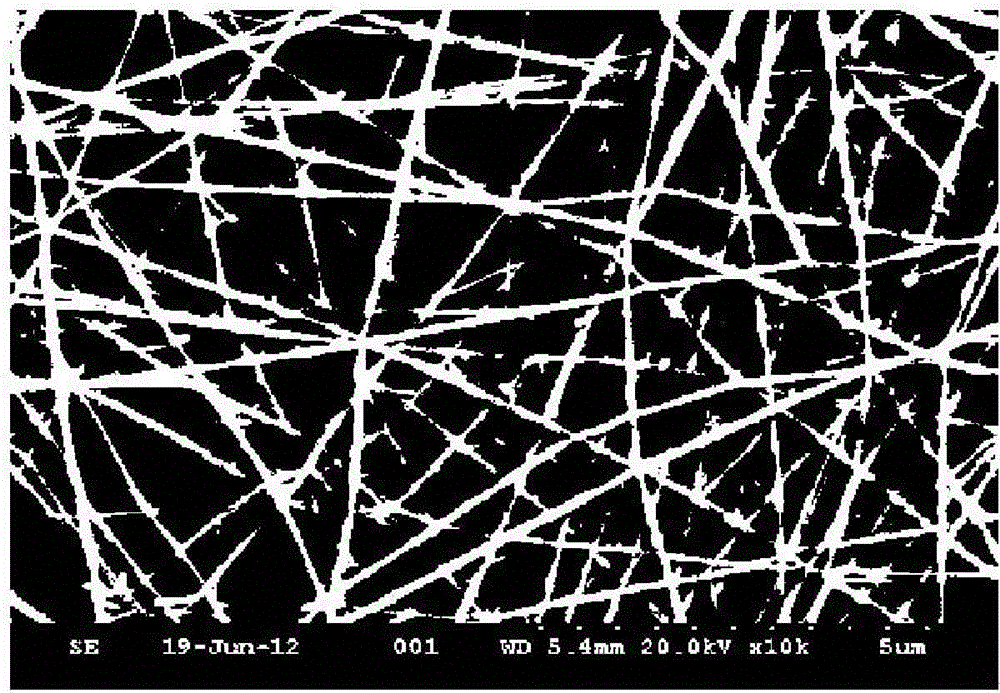

[0035] Prepare a precursor solution containing 2.0 wt% DEA, and then use this solution to prepare TiO by electrospinning 2 Glass coating. The specific steps are as follows: First, take 4.0g tetrabutyl titanate, 10.0g acetic acid and 8.0g ethanol in a closed container and stir for about 30min to obtain the first homogeneous sol; in addition, take 1.6g PVP and slowly add 4.0g DMF and 12.0g ethanol solution Stir continuously in the medium for more than 12h until the PVP is completely dissolved to obtain the second sol; mix the above two sols and add 2.0 wt% DEA and stir evenly to obtain the precursor solution for electrospinning. Ordinary glass slides were placed in deionized water, acetone, ethanol and isopropanol in sequence and ultrasonically cleaned, and placed at 80 o C is dried for later use. The flat collection device directly below the electrospinning nozzle is wrapped with aluminum foil, and the clean glass substrate is placed on the flat collection device. T...

Embodiment 3

[0037] Prepare a precursor solution containing 4.0 wt% DEA, and then use this solution to prepare TiO by electrospinning 2 Glass coating. The specific steps are as follows: First, take 4.0g tetrabutyl titanate, 10.0g acetic acid and 8.0g ethanol in a closed container and stir for about 30min to obtain the first homogeneous sol; in addition, take 1.6g PVP and slowly add 4.0g DMF and 12.0g ethanol solution Stir continuously in the medium for more than 12h until the PVP is completely dissolved to obtain the second sol; mix the above two sols and add 4.0 wt% DEA and stir evenly to obtain the precursor solution for electrospinning. Ordinary glass slides were placed in deionized water, acetone, ethanol and isopropanol in sequence and ultrasonically cleaned, and placed at 80 o C is dried for later use. The flat collection device directly below the electrospinning nozzle is wrapped with aluminum foil, and the clean glass substrate is placed on the flat collection device. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com