Iron oxide red and preparation method thereof

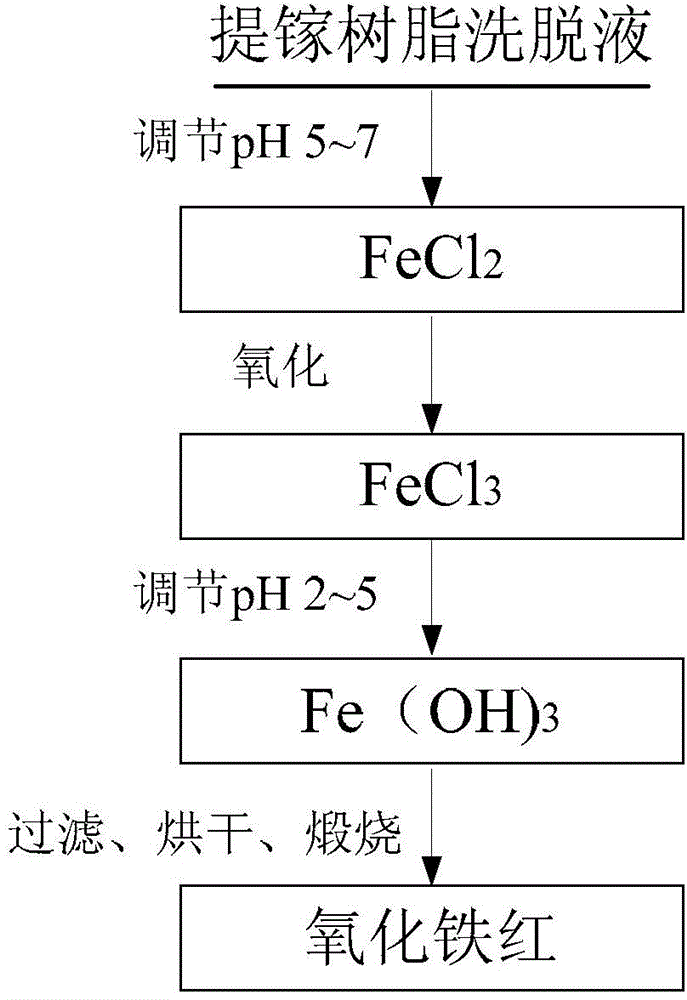

A technology of iron oxide red and iron hydroxide, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of high transportation cost, low value of ferric chloride, and difficulty in market expansion, so as to save energy and shorten Process flow and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

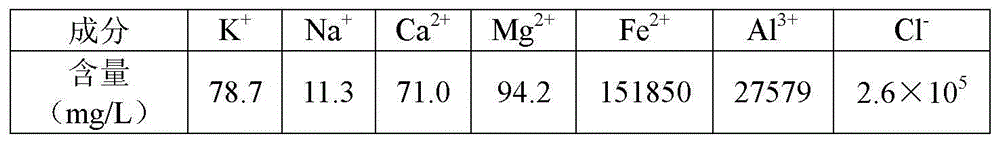

[0033]1) Weigh 250ml of the gallium-extracting resin eluent, add 2mol / L ammonia water to the gallium-extracting resin eluent at room temperature, adjust the pH of the gallium-extracting resin eluent to 6, stir and oxidize, and make the gallium-extracting resin elute The aluminum ions contained in the dehydration and the oxidized ferric ions form aluminum hydroxide and iron hydroxide precipitates. Filter to obtain ferrous chloride solution.

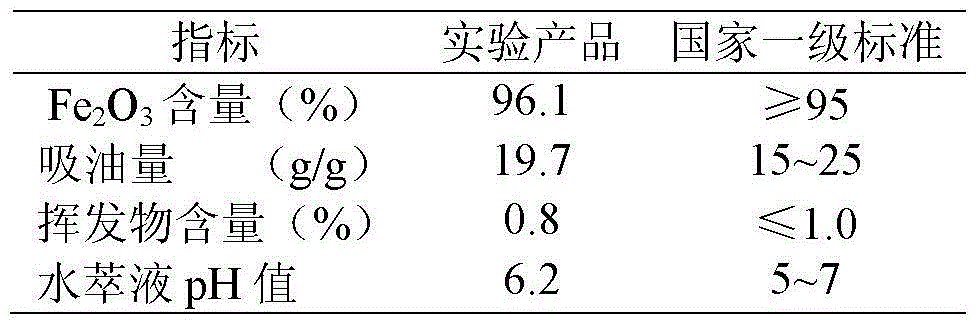

[0034] 2) Feed into the ferrous chloride solution with a flow rate of 30L / h of oxygen (the feed of oxygen is based on the complete oxidation of ferrous iron in the solution to ferric iron as a standard) to generate ferric chloride solution. Adopt the ammoniacal liquor of concentration 2mol / L to adjust the pH of ferric chloride solution to be 4, make it generate ferric hydroxide precipitate; Filter, adopt spray washing, remove the potassium, sodium, calcium and magnesium plasma adsorbed on the surface of ferric hydroxide precipitate, obtain...

Embodiment 2

[0040] 1) Weigh 250ml of the gallium-extracting resin eluent, add ammonia water with a concentration of 3mol / L to the gallium-extracting resin eluent at room temperature, adjust the pH of the gallium-extracting resin eluent to 5, stir and oxidize, and make the gallium-extracting resin eluate The aluminum ions contained in the resin eluent and the oxidized ferric ions form aluminum hydroxide and iron hydroxide precipitates. Filter to obtain ferrous chloride solution.

[0041] 2) Feed into the ferrous chloride solution to make it generate ferric chloride solution with a flow rate of 50L / h of oxygen. Use 2mol / L ammonia water to adjust the pH of the ferric chloride solution to 2 to make it generate ferric hydroxide precipitate; filter and use spray washing to remove the potassium, sodium, calcium and magnesium plasma adsorbed on the surface of the ferric hydroxide precipitate to obtain pure precipitation of ferric hydroxide.

[0042] 3) The ferric hydroxide precipitate was dried...

Embodiment 3

[0047] 1) Weigh 250ml of the gallium-extracting resin eluent, add 4mol / L ammonia water to the gallium-extracting resin eluent at room temperature, adjust the pH of the gallium-extracting resin eluent to 7, stir and oxidize, and make the gallium-extracting resin elute The aluminum ions contained in the dehydration and the oxidized ferric ions form aluminum hydroxide and iron hydroxide precipitates. Filter to obtain ferrous chloride solution.

[0048] 2) Feed into the ferrous chloride solution to make it generate ferric chloride solution with a flow rate of 35L / h. Adopt 4mol / L ammonia water to adjust the pH of ferric chloride solution to be 5 to make it generate ferric hydroxide precipitate; filter, adopt spray washing to remove potassium, sodium, calcium and magnesium plasma adsorbed on the surface of ferric hydroxide precipitate to obtain pure precipitation of ferric hydroxide.

[0049] 3) The ferric hydroxide precipitate was dried in an oven at 110°C, and then calcined in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com