Automatic hydraulic braking pressure supply device for unmanned aerial vehicle

A technology for hydraulic braking and unmanned aerial vehicles, which is applied to braking transmissions, aircraft braking arrangements, brakes, etc., can solve the problems of limited installation location, high cost, and high system failure rate, and achieves simple connection and failure. The effect of low rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

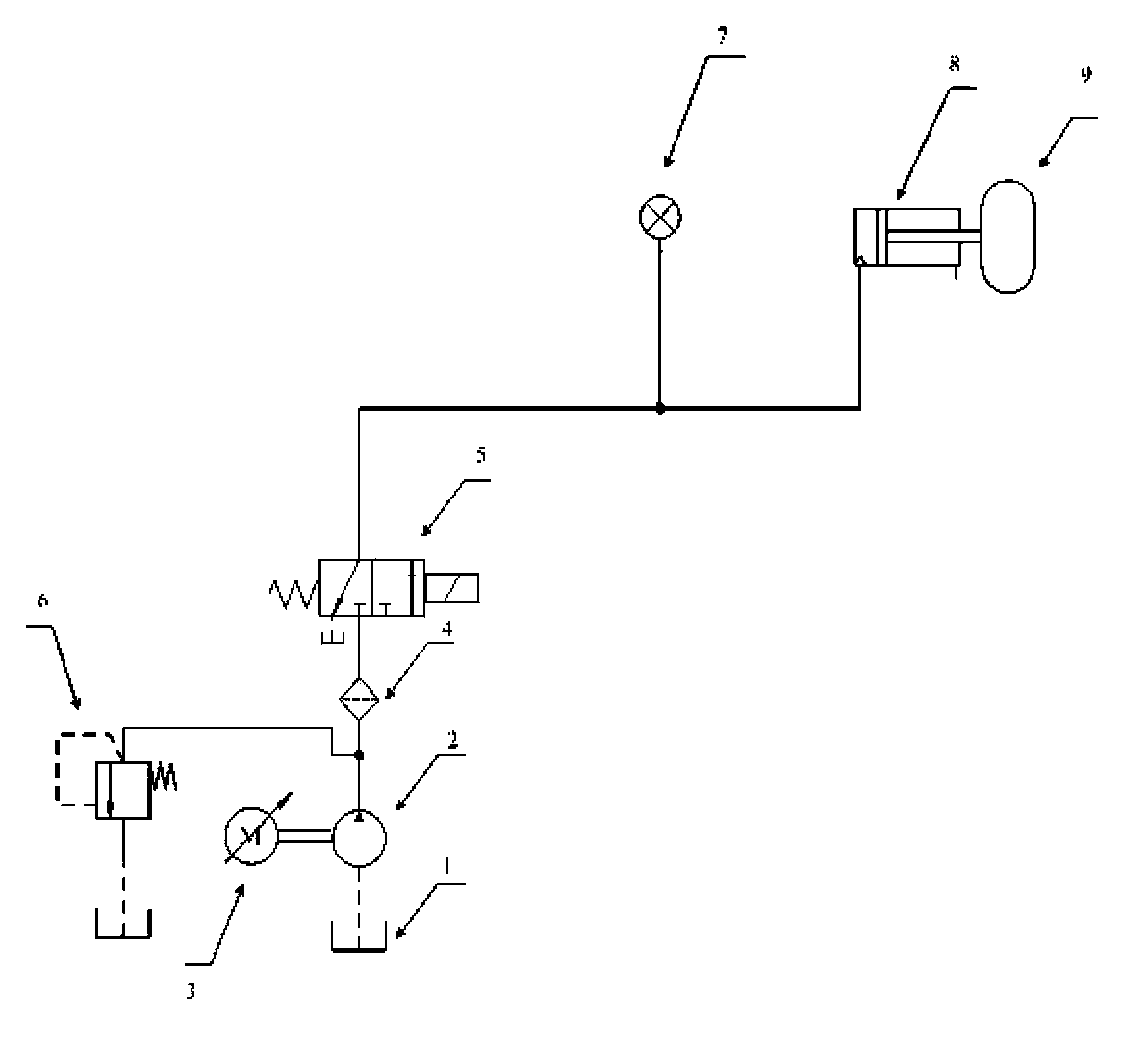

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. The UAV automatic hydraulic brake pressure supply device includes a hydraulic oil tank 1, a quantitative hydraulic pump 2, a frequency conversion motor 3, an oil filter 4, a brake valve 5, an overflow valve 6, a brake sensor 7, a brake actuator 8, and a quantitative hydraulic pump 2 The drive shaft of the fixed displacement hydraulic pump 2 is connected to the output shaft of the variable frequency motor 3, the oil suction port of the quantitative hydraulic pump 2 is connected to the oil tank 1, the oil outlet of the quantitative hydraulic pump 2 is connected to one end of the oil filter 4 and the overflow valve 6, and the other end of the oil filter 4 One end is connected to the inlet of the brake valve 5, and the outlet of the brake valve 5 is connected to one end of the brake pressure sensor 7 and the brake cylinder 8 respectively.

[0013] The pressure of the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com