Multi-wire cutting machine

A technology of multi-wire cutting machine and pay-off wheel, which is applied in the field of machinery and can solve problems such as uneven tension of steel wires and short distance between guide wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

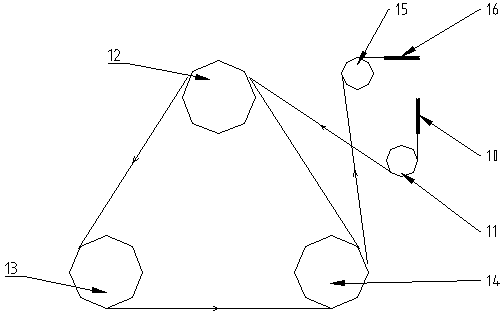

[0014] See attached figure 1 , 2 , a multi-wire cutting machine shown in the embodiment of the present invention, it at least includes a bed, a working panel, a rear panel, three sheaves 12, 13, 14 distributed in the shape of a finished product are installed on the working panel, and the rear panel is installed There are pay-off wheel 1, take-up wheel 24, and a guide wheel 2 and four guide wheel connecting rods are also installed on the rear panel, which are respectively 25, 26, 27, 28, and one is respectively installed on both sides of each guide wheel connecting rod. The guide wheels are respectively guide wheels 3, 4, 5, 6, 20, 21, 22, 23, and there are also a plurality of reversing wheels 7, 8, 9, 10, 11, 15, 16, 17, 18, 19, after steel wire is released by pay-off wheel 1, guide wheel 2, guide wheel 3, 4, 5, 6, multiple reversing wheels 7, 8, 9, lead to the front working panel successively, and Through the reversing wheel 10, it is wound around three sheaves 12, 13, 14 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com