Rubber stripping and cutting machine

A peeling and cutting machine and rubber technology, which is applied in the direction of dust removal, metal processing, and separation of dispersed particles. It can solve the problems of dust affecting the yield rate, affecting work efficiency, and affecting the thickness of finished products. It achieves high precision of screw transmission and simple operation. Convenience and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

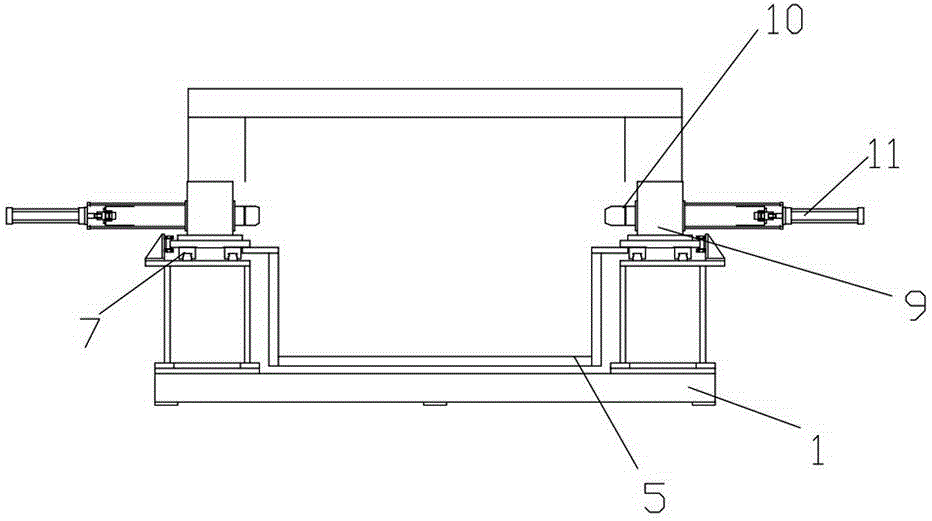

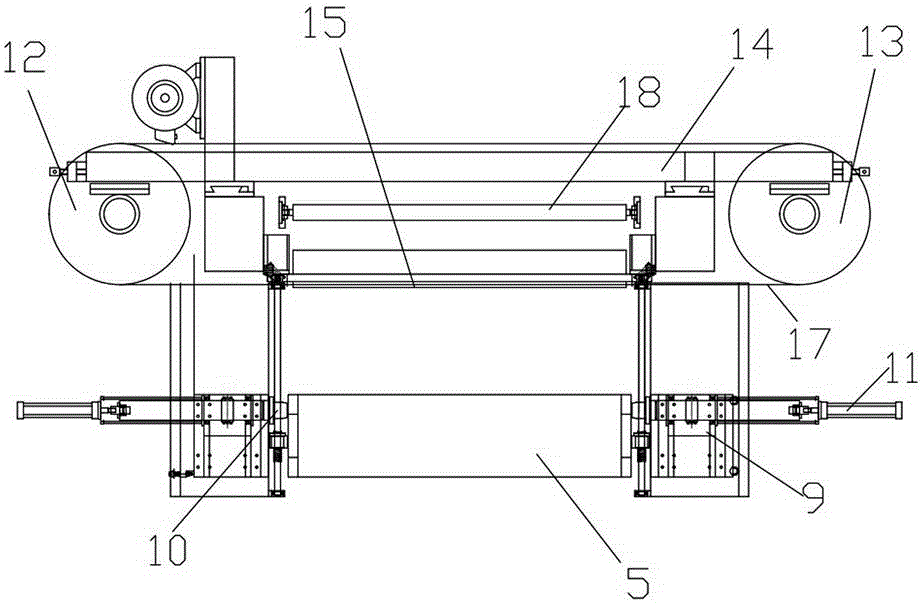

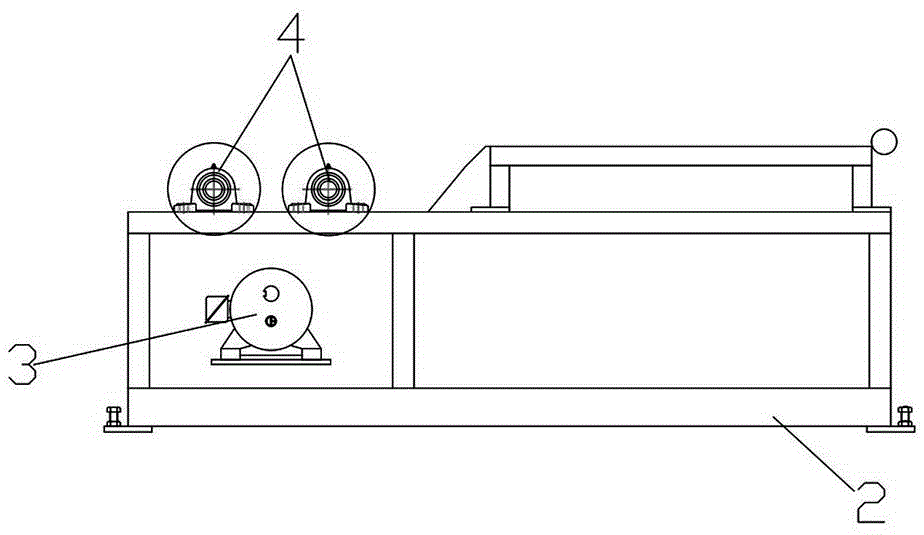

[0035] In this embodiment, refer to Figure 1 ~ Figure 4The specific implementation structure of the rubber peeling and cutting machine includes a frame-type base 1 and a propulsion device 5 installed on the base 1, a feeding device 9 and a dynamic blade device, and an independent winding material device and a control electric box are connected externally, and the control The electric box includes a PLC control system and an operation panel, and the operation panel includes a parameter setting panel, a start button, a stop button and an emergency stop button. The thickness value of the stripped and cut rubber coil can be directly set on the parameter setting panel, so as to automatically adjust the propulsion value of the propulsion device 5 and the rotating speed of the feeding device 9 through the program of the PLC control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com