Microwave output energy controllable pyrolysis method and device of unit mass reactors

A technology of unit mass and output energy, applied in the field of biomass energy and oleochemical energy, which can solve the problems of insufficient research on microwave cracking furnace, affecting the quality of green chemicals, and temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

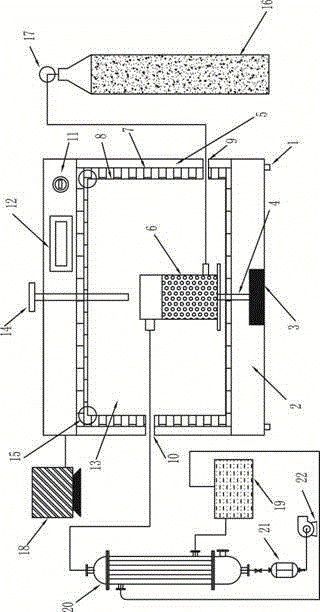

[0020] Add 500g of dried eucalyptus oil saponification into the quartz reactor (6), and the quartz reactor (6) is connected to the gas storage cylinder (16) and the condenser (20) respectively, and the gas storage (inert gas or reducing gas) is adjusted ) the flow meter (17) of the steel cylinder (16) to the maximum opening, turn on the switch of the gas storage cylinder (16), adjust the valve to an appropriate opening, and flush the reaction system for 2 minutes. Adjust the temperature of the cooling water circulation system (20) to 0°C, and adjust the negative pressure system of the air pump (22) to 0.2 bar. Close the cracking furnace door, turn on the microwave cracking instrument switch (11), select the weight control mode through the LED display touch control panel (12), adjust the power to 1500W, and set the power-weight automatic adjustment program to 3W / g (each reduction in the mass of the reactant The microwave output power of 1g is reduced by 3W), the reaction time i...

Embodiment 2

[0022] Add 500g of dry tallow ester oil saponification into the quartz reactor (6), and the quartz reactor (6) is connected to the gas storage cylinder (16) and the condenser (20) respectively, and the gas storage (inert gas or reducing gas) is adjusted The flow meter (17) of the steel cylinder (16) reaches the maximum opening, open the switch of the gas storage cylinder (16), adjust the valve to an appropriate opening, and flush the reaction system for 2 minutes. Adjust the temperature of the cooling water circulation system (20) to 0°C, and adjust the negative pressure system of the air pump (22) to 0.2 bar. Close the pyrolysis furnace door, open the microwave pyrolysis instrument switch (11), select the weight control mode through the LED display touch control screen (12), adjust the power to 1500W, and set the power-weight automatic adjustment program to 4W / g (each reduction in the mass of the reactant The microwave output power of 1g is reduced by 4W), the reaction time i...

Embodiment 3

[0024] Add 200g of dry bagasse (after 10% phosphoric acid treatment) into the quartz reactor (6), and the quartz reactor (6) is connected to the gas storage cylinder (16) and the condenser (20) respectively, and adjust the gas storage (inert gas or reducing When the flow meter (17) of the steel cylinder (16) reaches the maximum opening, turn on the switch of the gas storage cylinder (16), adjust the valve to an appropriate opening, and flush the reaction system for 2 minutes. Adjust the temperature of the cooling water circulation system (20) to 0°C, and adjust the negative pressure system of the air pump (22) to 0.2 bar. Close the pyrolysis furnace door, open the microwave pyrolysis instrument switch (11), select the weight control mode through the LED display touch control screen (12), adjust the power to 2000W, set the power-weight automatic adjustment program to 10W / g (each reduction in the mass of the reactant The microwave output power of 1g is reduced by 10W), the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com