Method for preparing high-specific-capacity lithium-enriched lithium battery material

A lithium battery material, high specific capacity technology, used in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of poor and low conductivity, requiring tens of minutes or even hours, and low capacity. The effect of improving cycle stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

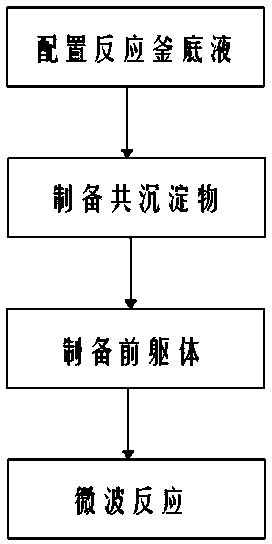

[0032] A preparation method of a high specific capacity lithium-rich lithium battery material, the chemical formula of the high specific capacity lithium-rich lithium battery cathode material is xLi 2 MnO 3 ·(1-x)Li Ni x co y mn 1-x-y o 2 , wherein 0.4≤x≤0.6, 0.2≤y≤0.5, 0.2≤z≤0.35, its preparation method comprises the following steps:

[0033] a. Configure the bottom liquid of the reaction kettle, add a solvent to the nickel source compound, manganese source compound, and cobalt source compound for dissolution, and configure soluble cobalt salt, nickel salt, and manganese salt solutions respectively, with a concentration of 0.5-2.5mol / L, using 30 % of cobalt salt solution, nickel salt solution or manganese salt solution is added to the reactor as the bottom liquid of the reactor;

[0034] b. Prepare co-precipitate, configure a precipitant solution with a concentration of 0.5-2.5mol / L, and add the precipitant solution and the remaining cobalt salt solution, nickel salt sol...

Embodiment 1

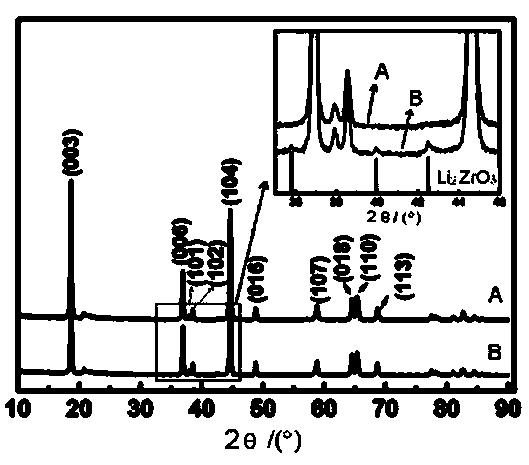

[0039] Press 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Weigh a total of 3988 grams of nickel sulfate, manganese sulfate and cobalt sulfate, add 20L deionized water to dissolve completely, and drop Na at a concentration of 2.2mol / L within 1 hour. 2 CO 3 Solution 10L, co-precipitation reaction temperature maintained at 50 ° C, stirring rate 1000rpm coprecipitation reaction for 3 hours.

[0040] The co-precipitation suspension was filtered and washed three times with water, and transferred to a blast drying oven for 6 hours at 100 °C.

[0041] According to the mass ratio of zirconia: coprecipitate (1.5:97.5), Li was added according to the stoichiometric ratio 2 CO 3 , mixed and ball milled for 3 hours.

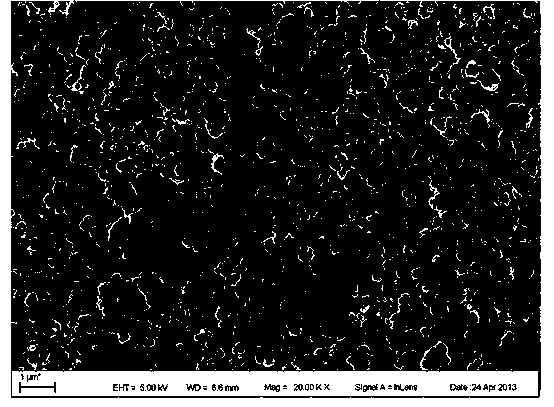

[0042] The obtained precursor was pressed into a disc with a thickness of 2.5 cm under a pressure of 2 MPa. Place the sample piece in a microwave high-temperature reaction furnace for reaction, and within 5 minutes, the material block absorbs microwaves and heats up t...

Embodiment 2

[0048] Prepare the precursor as in Example 1.

[0049] The obtained precursor was compressed into a tablet under a pressure of 3 MPa, with a thickness of 4 cm. Within 6 minutes, the material block absorbs microwaves and heats up to 800°C; control the microwave heating power, and react with microwaves at 800°C for 2 minutes. After the microwave reaction is completed, the lithium-rich layered positive electrode material is rapidly cooled under the action of air cooling and water cooling, and the obtained sample is fully ball milled. (below with embodiment 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com