A core-shell structure lixv2o5/liv3o8 lithium intercalation material and its preparation method

A core-shell structure and composite nanomaterial technology is applied in the field of high-performance composite lithium vanadate positive electrode material with core-shell structure and its preparation, which can solve the problems of poor rate performance and short cycle life, and improve the cycle stability performance. , The effect of improving cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

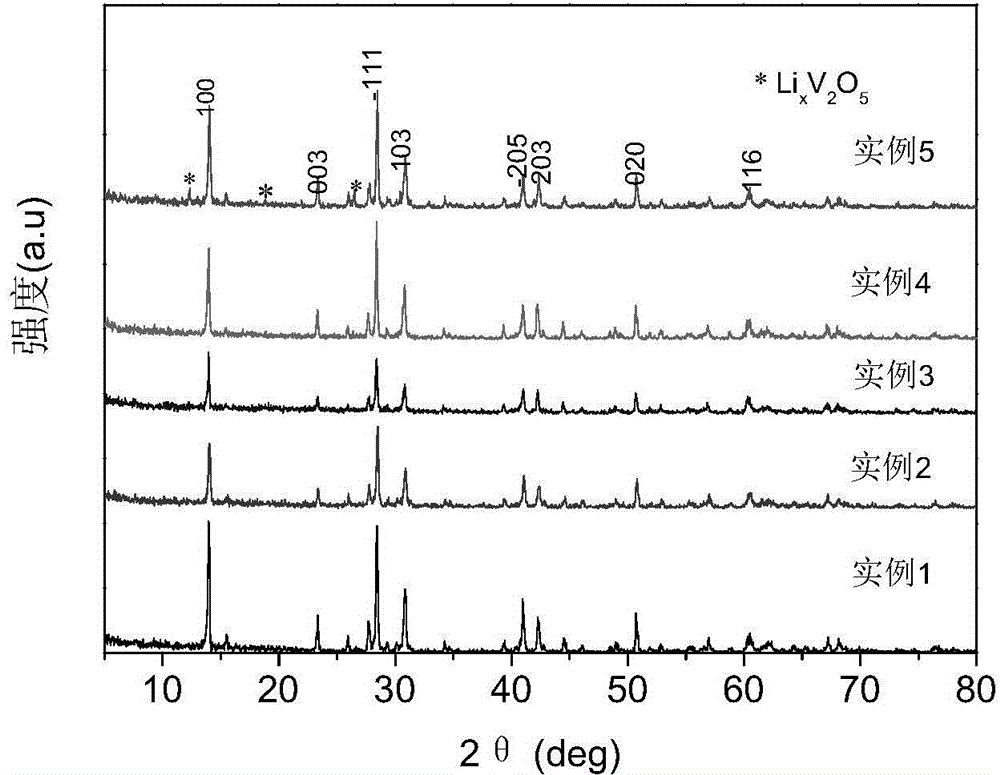

[0028] Weigh 2.5g flake LiV 3 o 8 Nanomaterials are placed in a tube furnace. at 120cm 3 The flow rate of / min is continuously injected with argon protective gas. After half an hour, it is heated to 450°C at a heating rate of 15°C / min for 10 minutes, and the tube furnace is turned off, and it is naturally cooled to room temperature to obtain LiV without reducing gas treatment. 3 o 8 , for comparative studies. The crystal structure of the material is shown in figure 1 Example 1 in . It can be seen from the XRD curve that the prepared product belongs to the monoclinic crystal system, P2 1 / m point group.

[0029] Mix the prepared target material, conductive agent Super P, and binder PVDF uniformly in a certain mass ratio (80:10:10), use tetrahydrofuran (THF) as the solvent, stir thoroughly for 6 hours, and use a film applicator to quickly spread the slurry Spread evenly on aluminum foil. After the solvent evaporates, place the coated pole piece in a vacuum drying oven a...

Embodiment 2

[0031] Weigh 2.52g flake LiV 3 o 8 Nanomaterials are placed in a tube furnace. at 120cm 3 The flow rate of / min is continuously injected with argon protective gas. After half an hour, it is heated to 450°C at a heating rate of 15°C / min for 10 minutes, and the argon flow is immediately switched to H. 2 / Ar(H 2 volume 5%) mixed gas, H 2 / Ar mixed gas flow rate is 60cm 3 / min, stop the gas injection after 1min of treatment, close the tube furnace, and cool down to room temperature naturally to obtain the target material. Its crystal structure is shown in figure 1 Example 2 in . It can be seen from the XRD curve that the prepared product belongs to the monoclinic crystal system, P2 1 / m point group, there is no obvious impurity diffraction peak, indicating that 1min H 2 Heat treatment in LiV / Ar mixed gas 3 o 8 Li formed on the surface x V 2 o 5 The content is very small, below the detection limit of XRD diffraction.

[0032] The manufacturing process and testing of ...

Embodiment 3

[0034] Weigh 2.52g flake LiV 3 o 8 Nanomaterials are placed in a tube furnace. at 120cm 3 The flow rate of / min is continuously injected with argon protective gas. After half an hour, it is heated to 450°C at a heating rate of 15°C / min for 10 minutes, and the argon flow is immediately switched to H. 2 / Ar(H 2 volume 5%) mixed gas, H 2 / Ar mixed gas flow rate is 60cm 3 / min, stop the gas injection after 5 minutes of treatment, turn off the tube furnace, and let it cool down to room temperature naturally to obtain the target material. Its crystal structure is shown in figure 1 Example 3 in . It can be seen from the XRD curve that the prepared product belongs to the monoclinic crystal system, P2 1 / m point group, there is no obvious impurity diffraction peak, indicating that 5min H 2 / Ar mixed gas heat treatment in LiV 3 o 8 Li formed on the surface x V 2 o 5 Also rarely, its content is below the detection limit of XRD diffraction.

[0035] The manufacturing proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com