Two-stage lithium bromide absorption heat pump unit with refrigerant water preheater

A technology of lithium bromide absorption and heat pump units, which is applied in the direction of refrigerators, refrigeration and liquefaction, and machines using waste heat, etc., can solve the problems that the temperature rise of hot water cannot be further increased, waste heat cannot be recycled, and energy consumption increases, etc., to achieve load reduction , heat transfer area is reduced, the effect of increasing the absorption pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

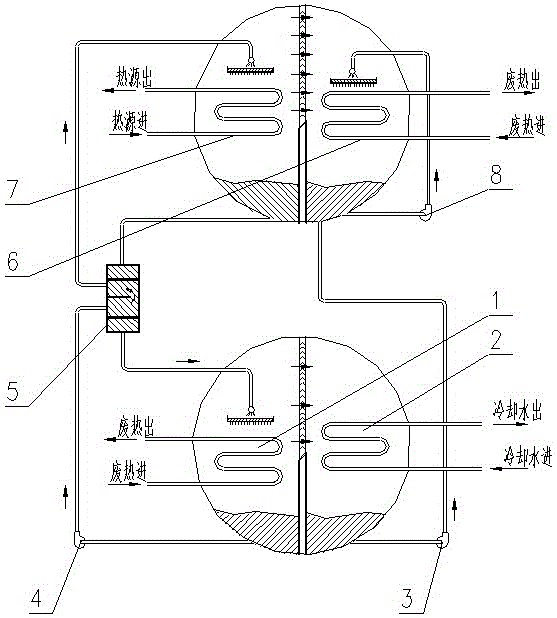

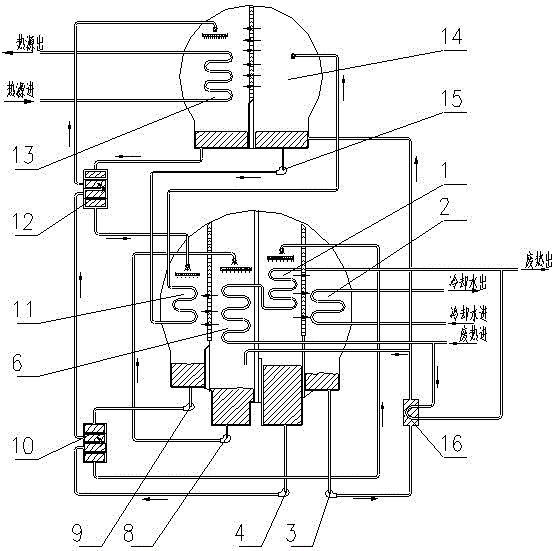

[0032] like figure 2 As shown, a two-stage lithium bromide absorption heat pump unit with a refrigerant water preheater includes a generator 1, a condenser 2, an evaporator 6, a primary absorber 11, a secondary absorber 13, and a flash evaporator 14. Low temperature solution heat exchanger 10, high temperature solution heat exchanger 12, concentrated solution pump 4, refrigerant pump 3, evaporator refrigerant circulation pump 8, dilute solution pump 9, flash refrigerant circulation pump 15, refrigerant water Preheater 16, control system (not shown in the figure) and pipelines connecting various components, etc. The secondary absorber 13 and the flash evaporator 14 are in the same cylinder and placed above; the primary absorber 11, the evaporator 6, the generator 1 and the condenser 2 are in the same cylinder, separated by a partition into two independent The cavity is placed below, the primary absorber 11 and the evaporator 6 are in the same cavity, and the generator 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com