Water vapor vacuum rapid drying system and working method

A drying system, vacuum fast technology, applied in the direction of drying solid materials, drying gas arrangement, method combination to dry solid materials, etc., can solve the problems of limiting the use of superheated steam drying system, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

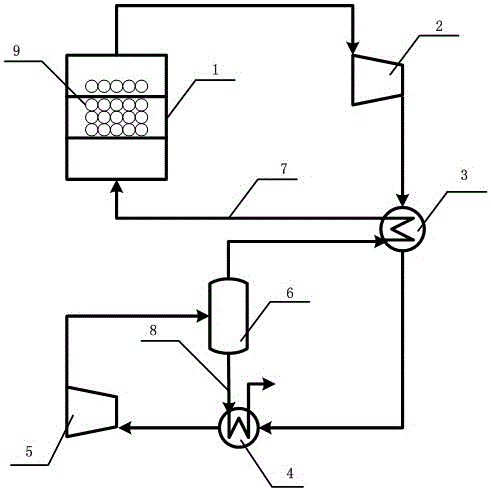

[0019] Refer below figure 1 Describe the working process of the energy-saving and high-efficiency vacuum drying system.

[0020] Firstly, the dryer 1 is evacuated to a certain degree, and then the compressor 2 and the expander 5 are turned on to make the drying system work, so that the system runs smoothly.

[0021] The superheated steam 7 passes through the dryer 1 as a drying medium. Due to the concentration difference between the drying medium and the material to be dried 9, the superheated steam takes out the moisture in the material and becomes a superheated steam with a small superheat, and then compressed by the compressor 2. , the temperature and pressure of the steam rise, and then enter from the hot side of the first heat exchanger 3, the steam releases heat in the first heat exchanger 3, and the temperature of the steam decreases; the outlet of the hot side of the first heat exchanger 3 is connected with the second The hot side inlet of the heat exchanger 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com