Transmission mechanism used for reciprocating compressor

A transmission mechanism and compressor technology, applied in the field of mechanical transmission, can solve the problems of multi-structure and complexity of moving parts, increase the actual production cost of the machine body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

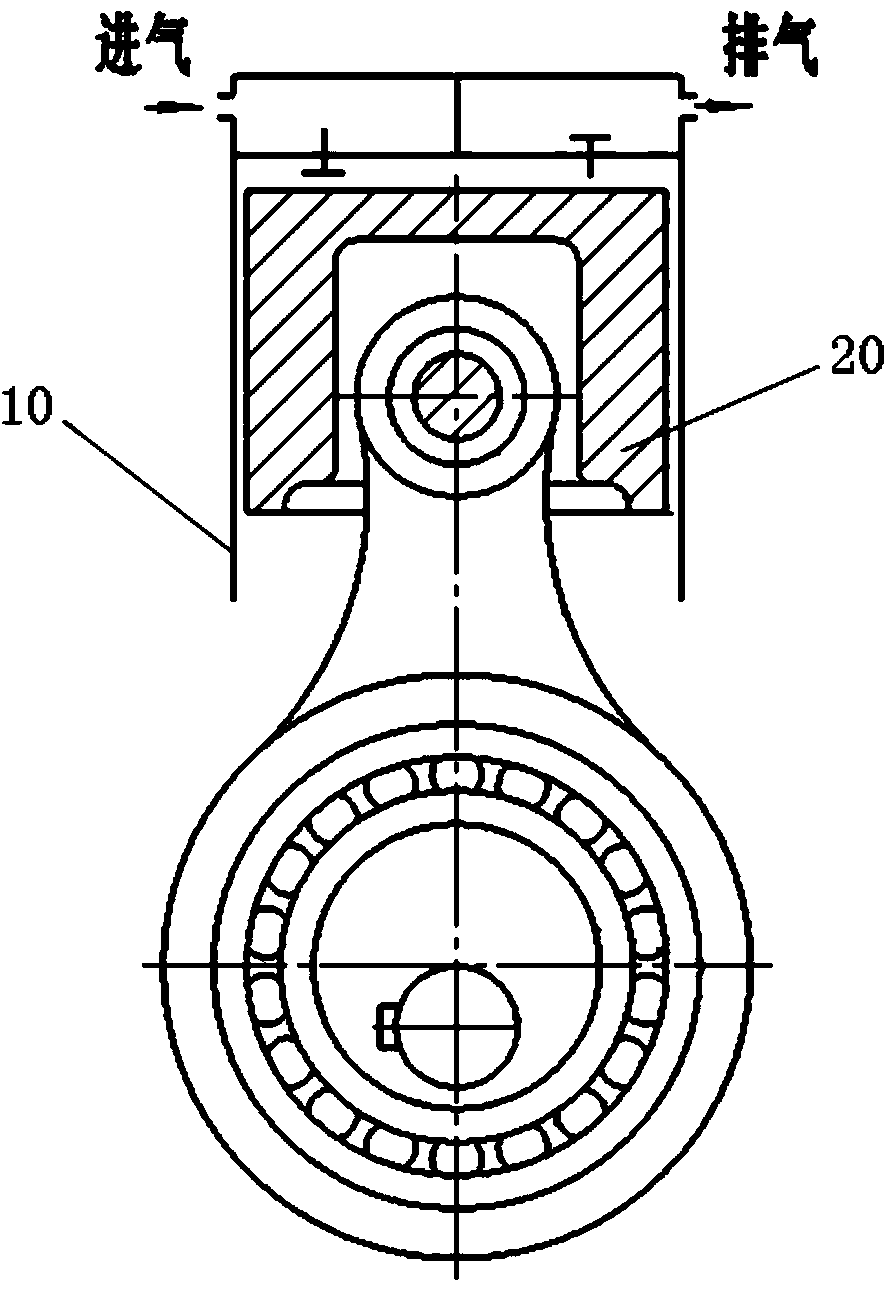

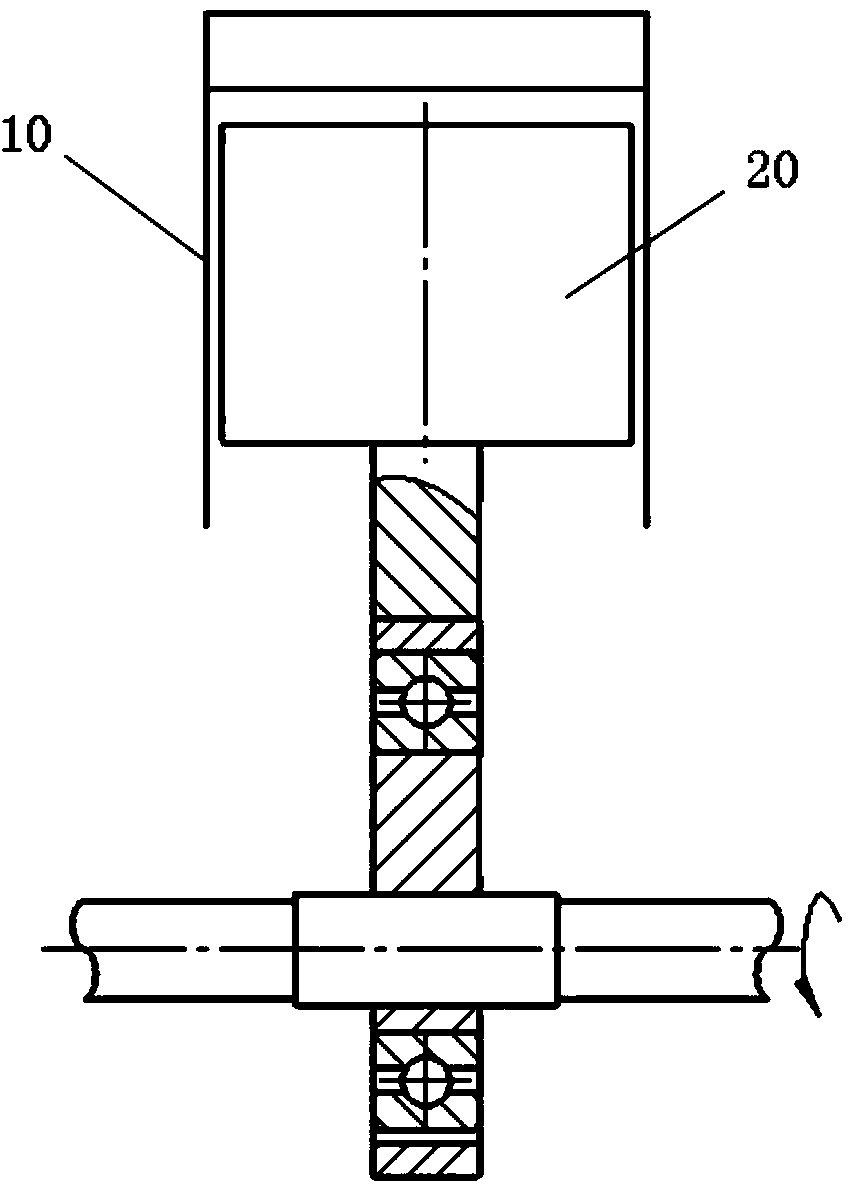

[0024] For ease of understanding, here in conjunction with accompanying drawing, specific testing device of the present invention and its operation process are further described as follows:

[0025] Such as Figure 3-6 As shown, the present invention transmits power through the transmission yoke 50, and the piston 20, the connecting rod 30 and the transmission yoke 50 are fixedly connected among the three; of course, the above three can also be made into an integrated connection structure, and its structure is obviously compared with The existing hinge structure is simpler and easier to implement, and can fundamentally eliminate the friction and wear between the connecting rod and the piston; in addition, during operation, the rolling bearing in the eccentric part 40 only needs to meet the requirements of continuous movement in the transmission yoke 50. The power can be transmitted by rolling, and the axial installation between the rolling bearing and the transmission yoke 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com