Pulping equipment based on reciprocating flow disturbance and pressure jet impact type pulping

An impact and pulping technology, which is applied in textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of low pulping efficiency, low pulp quality, single pulping method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

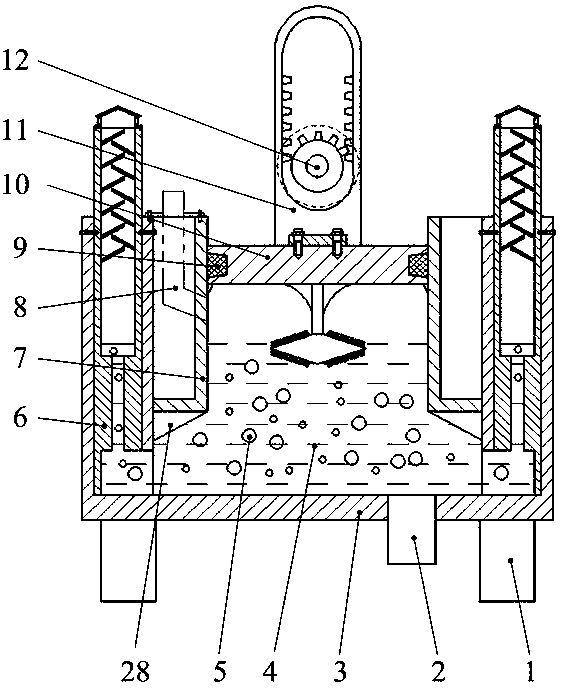

[0043] Such as figure 1 , figure 2 and image 3 As shown, a kind of pulping equipment based on reciprocating turbulence and pressure-jet impact pulping of the present invention mainly includes a slurry generating device, a power drive device, a reciprocating turbulence device and a pressure-impact pulping device, and the power drive device is installed Above the slurry generating device, the reciprocating flow turbulence device is installed in the barrel 3 generating device and below the power drive device, and the press crushing device is installed on the slurry generating device.

[0044] The present invention realizes the generation and output of the slurry through the slurry generating device, that is, the slurry is generated in the material barrel 3 in the slurry generating device, and is output through the slurry outlet 2; The punching pulp device provides reciprocating driving force and reciprocating pressure respectively, that is, the driving wheel 12 and driven rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com