Liquid packaging body paper board and preparation method thereof

A liquid and cardboard technology, applied in the field of liquid packaging raw cardboard and its preparation, can solve the problems of poor fiber bonding strength, high basis weight, and high pressure on fiber environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the above-mentioned liquid packaging raw cardboard, comprising the following steps:

[0043] After mixing 80-100wt% of unbleached kraft pulp and 0-20wt% of undried chemical broad-leaved fresh pulp, it is passed into the bottom headbox of the stacked wire paper machine;

[0044] After mixing 10-20wt% of undried chemical broad-leaved fresh pulp, 50-80wt% of unbleached kraft pulp and 5-30wt% of mechanical pulp, it is passed into the core layer headbox of the stacked wire paper machine;

[0045] After mixing 20-80wt% of undried chemical broad-leaved fresh pulp and 20-80wt% of chemical soft-leaved pulp, it is passed into the surface headbox of the stacked wire paper machine;

[0046] The base paper with the bottom paper layer, the core paper layer and the face paper layer is obtained by forming the three layers of the web by the stacking paper machine;

[0047] After drying the base paper for the first time, coatin...

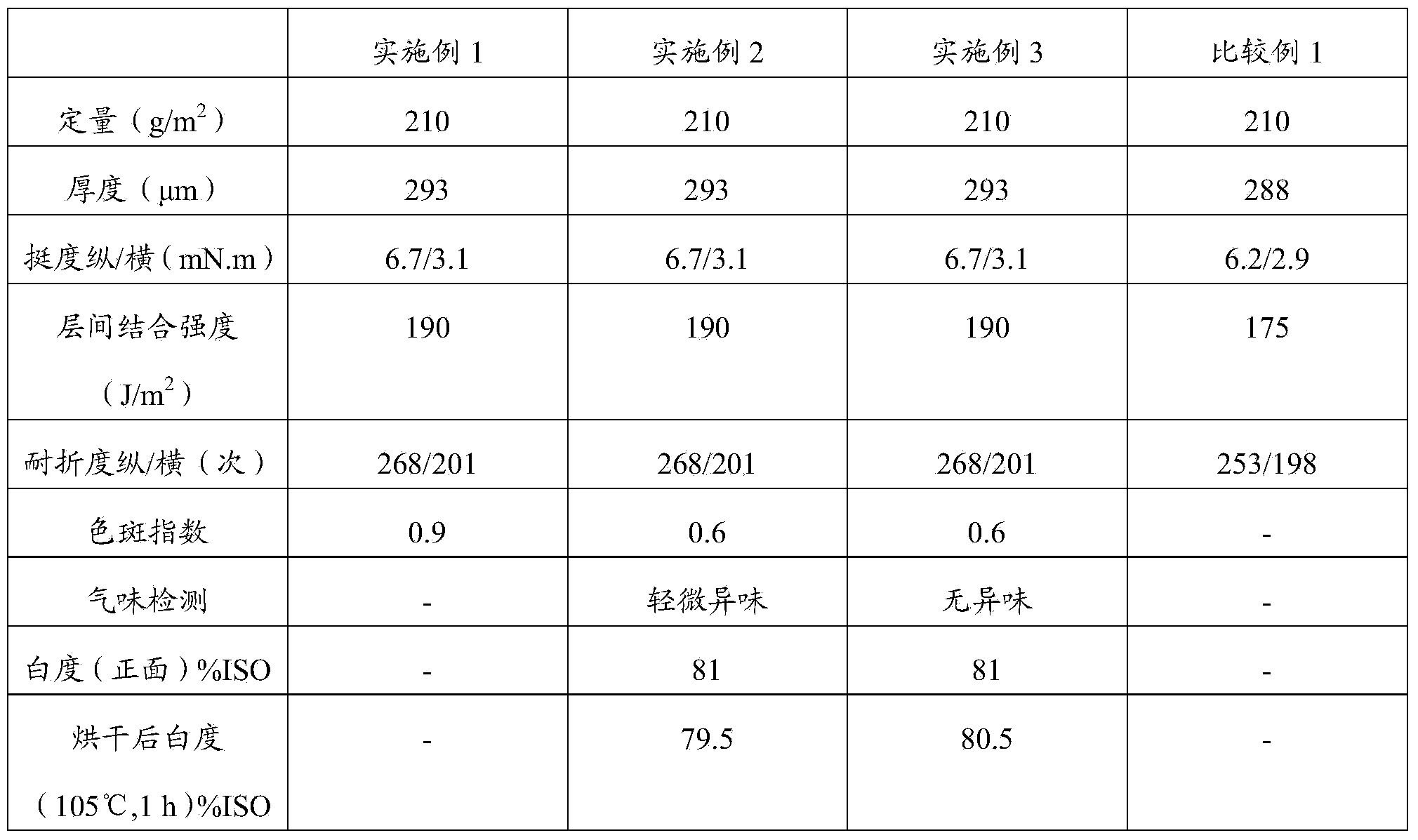

Embodiment 1

[0053] The basis weight of the face paper layer is 42g / m 2 , using 50wt% undried chemically bleached broadleaf fresh pulp and 50wt% chemically bleached softwood pulp board; the basis weight of the core paper layer is 115g / m 2 , using 10wt% undried chemically bleached broadleaf fresh pulp, 70wt% unbleached kraft softwood pulp board and 20wt% chemical mechanical pulp board; the basis weight of the bottom paper layer is 21g / m 2 , using 100wt% unbleached sulphate soft-leaf pulp; the above-mentioned pulp sheets are respectively disintegrated by a pulper, mixed with the above-mentioned components, screened, and beaten by a refiner, and mixed with the fresh pulp from the pulping line in the mixing tank. After mixing, it enters the surface layer headbox, core layer headbox and bottom headbox of the stacking paper machine respectively, and then is formed by three layers of the stacking paper machine to obtain a surface paper layer, a core paper layer and a bottom layer. The base paper...

Embodiment 2

[0057] The basis weight of the face paper layer is 42g / m 2 , using 50wt% undried chemically bleached broadleaf fresh pulp and 50wt% chemically bleached softwood pulp board; the basis weight of the core paper layer is 115g / m 2 , using 10wt% undried chemically bleached broadleaf fresh pulp, 70wt% unbleached kraft softwood pulp board and 20wt% chemical mechanical pulp board; the basis weight of the bottom paper layer is 21g / m 2 , using 100wt% unbleached sulphate soft-leaf pulp; the above-mentioned pulp sheets are respectively disintegrated by a pulper, mixed with the above-mentioned components, screened, and beaten by a refiner, and mixed with the fresh pulp from the pulping line in the mixing tank. After mixing, it enters the surface layer headbox, core layer headbox and bottom headbox of the stacking paper machine respectively, and then is formed by three layers of the stacking paper machine to obtain a surface paper layer, a core paper layer and a bottom layer. The base paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com