Iron removal method in acid aluminum smelting process

A technology of acid method and process, which is applied in the field of iron removal in the acid method aluminum smelting process, can solve the problems of unsatisfactory recovery and purification, and achieve the effect of good iron removal effect and easy industrial practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

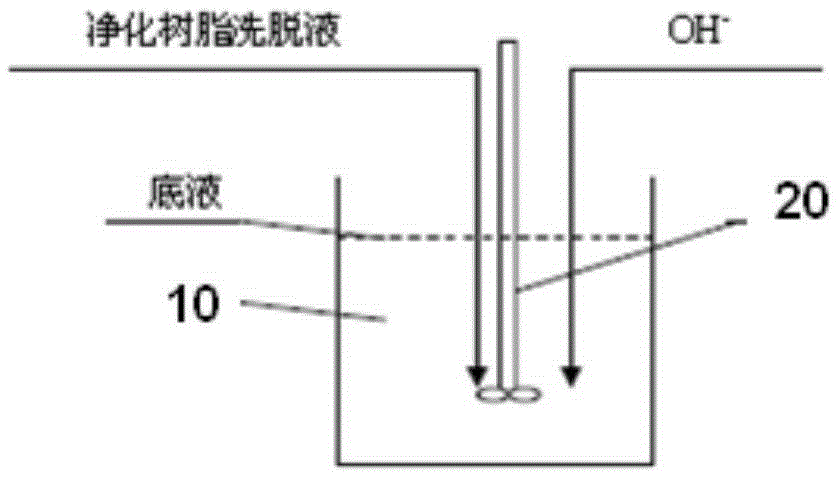

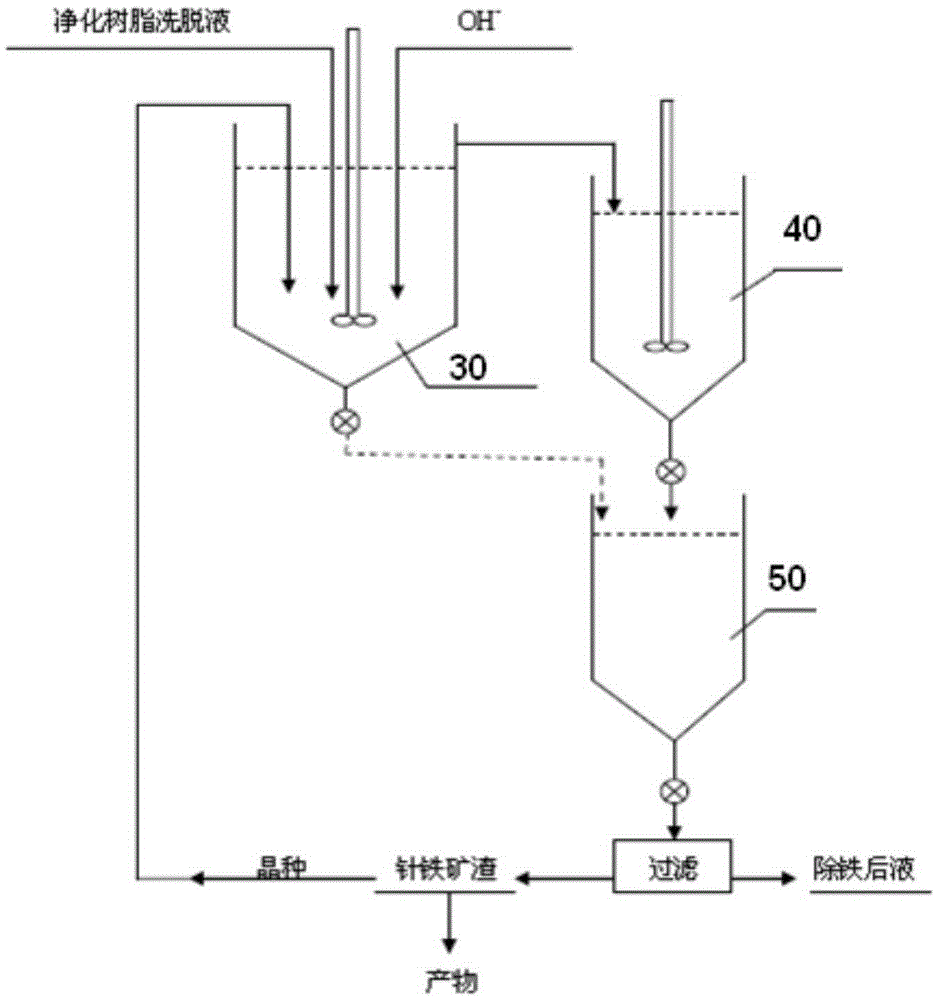

Image

Examples

Embodiment 1

[0042] (1) Take 1000ml of water or liquid after iron removal, pour it into a 1300ml stainless steel reaction tank, adjust the pH=2.0 with hydrochloric acid, adjust the temperature of the super constant temperature water bath to 90°C, start the stirrer, and stir slowly;

[0043] (2) When the temperature rises to 90°C, increase the stirring speed to 500r / min, take 2ml of purified resin eluent from the bottom of the reaction tank and add it to the bottom solution at one time, after 10min of reaction, add 1mol / L Na 2 CO 3 Adjust pH=2.0 with 12ml of solution;

[0044] (3) Repeat the feeding step until 80ml of purified resin eluent is added to obtain a goethite seed slurry of about 3g / L;

[0045] (4) Take 20ml of purified resin eluent from the bottom of the reaction tank and add it to the above-mentioned goethite seed slurry at one time. After 10 minutes of reaction, add 1mol / L Na 2 CO 3 Adjust pH=2.0 with 24ml of solution;

[0046] (5) Repeat the feeding step until 400ml of pur...

Embodiment 2

[0051] Except for step (2), the process conditions of other steps are the same as in Example 1. The process conditions of step (2) are adjusted to:

[0052] (2) When the temperature rises to 90°C, increase the stirring speed to 500r / min, take 4ml of the purified resin eluent from the bottom of the reaction tank and add it to the bottom solution at one time, and after 10min of reaction, use 1mol / L Na 2 CO 3 12ml of the solution was adjusted to pH=2.0.

[0053] It has been determined that in the solution after iron removal, the removal rate of iron is 99.7%, and the loss rate of gallium is less than 5.0%.

Embodiment 3

[0055] Except for step (2), the process conditions of other steps are the same as in Example 1. The process conditions of step (2) are adjusted to:

[0056](2) When the temperature rises to 90°C, increase the stirring speed to 500r / min, take 10ml of purified resin eluent from the bottom of the reaction tank and add it to the bottom solution at one time, after 10min of reaction, use 1mol / L Na 2 CO 3 12ml of the solution was adjusted to pH=2.0.

[0057] It has been determined that in the solution after iron removal, the removal rate of iron is 99.5%, and the loss rate of gallium is less than 5.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com