Desolventizer toaster special for tea seed meal

A technology of steaming off-line and tea meal, which is applied in the direction of fat production, fat oil/fat production, etc. It can solve the problems that the solvent is not easy to remove, block the feeding port, and is not conducive to the preservation of tea meal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

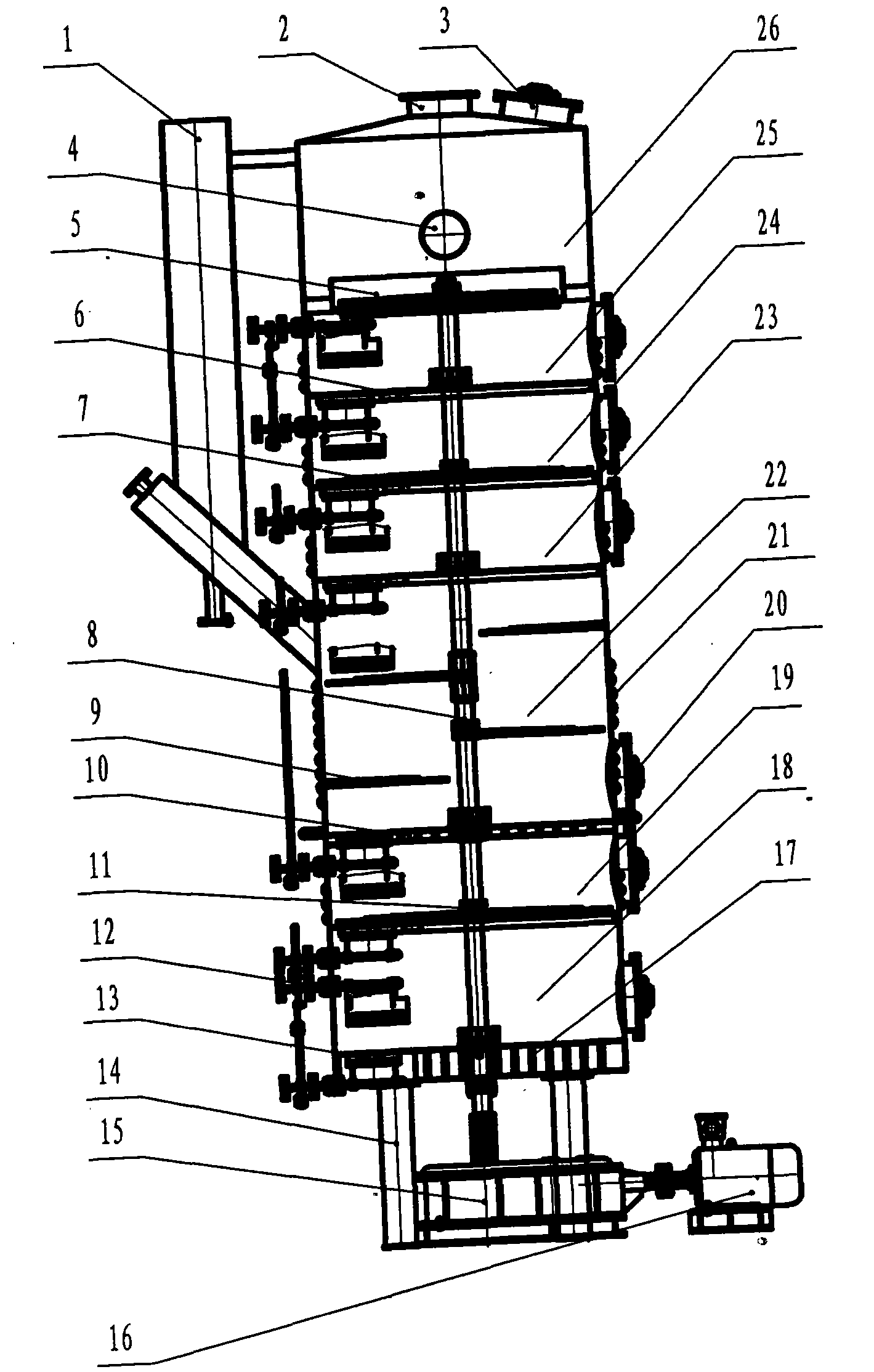

[0006] The products involved in this project are as follows: figure 1 As shown, the equipment is vertically arranged in the system through four pillars 14; the cylinder 26 is provided with a cooling layer 18, a drying layer 19, a high material layer 22, a pre-removal third layer 23, a pre-removal second layer 24, a pre-removal first layer Layer 25 has six layers in total; each layer is provided with outlets in a staggered direction. Side maintenance manhole 20, automatic material door 12 and indirect heating outer ring 21 are all provided on the side of each layer of cylinder body 26, and automatic material door 12 is connected with the material pendulum of the upper layer. A stirring knife 11 is provided at 5 millimeters above the plane of the cylinder body 26 from the pre-off disc 5, the steam permeable disc 6, the heating disc 7, the direct steam interlayer 10, and the air-cooled interlayer 17. The top of the cylinder body 26 is provided with a mixed steam outlet 2 and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com