A reactive rubber asphalt densely graded concrete and its design method

A rubberized asphalt, reactive technology, applied in the field of reactive rubberized asphalt densely graded concrete and its design, can solve the problems of comparable, storage, processing, transportation, mixing constraints, difficult road performance, etc., to save energy, reduce Heavy pollution and improved road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation process of reactive rubber asphalt, the mass parts of base asphalt, waste tire rubber blocks and reaction aids meet the following requirements:

[0034] Base asphalt 100 parts;

[0035] Waste tire rubber blocks 50-75 parts;

[0036] Reaction auxiliary agent 1.5~3.5 parts.

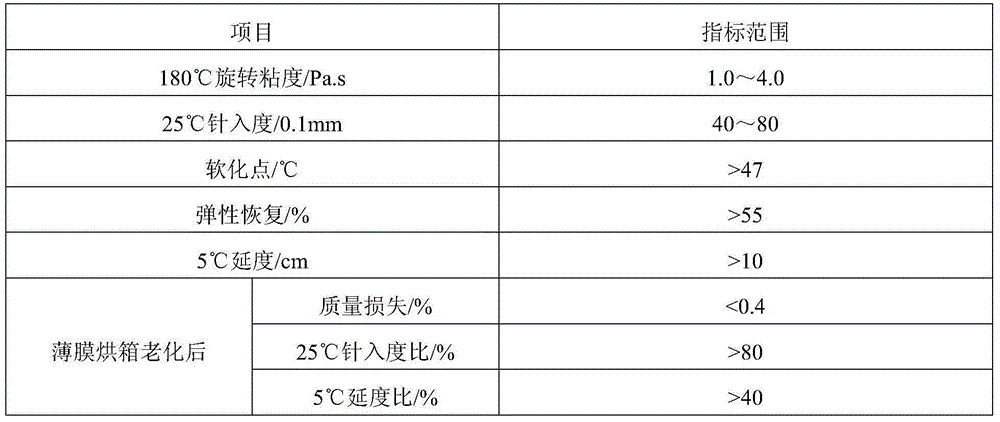

[0037] The technical indicators of the reactive rubber asphalt are as follows:

[0038] Basic indicators: rotational viscosity at 180°C / Pa.s: 1.0~4.0; penetration at 25°C / 0.1mm: 40~80; softening point / °C: >47; elastic recovery / %: >55; ductility at 5°C / cm:>10;

[0039] Indexes after film oven aging: mass loss / %: 80; 5°C ductility ratio / %: >40.

[0040] The technical indicators of reactive rubber asphalt are collected in Table 1 as follows:

[0041] Table 1 Technical indicators of reactive rubber asphalt

[0042]

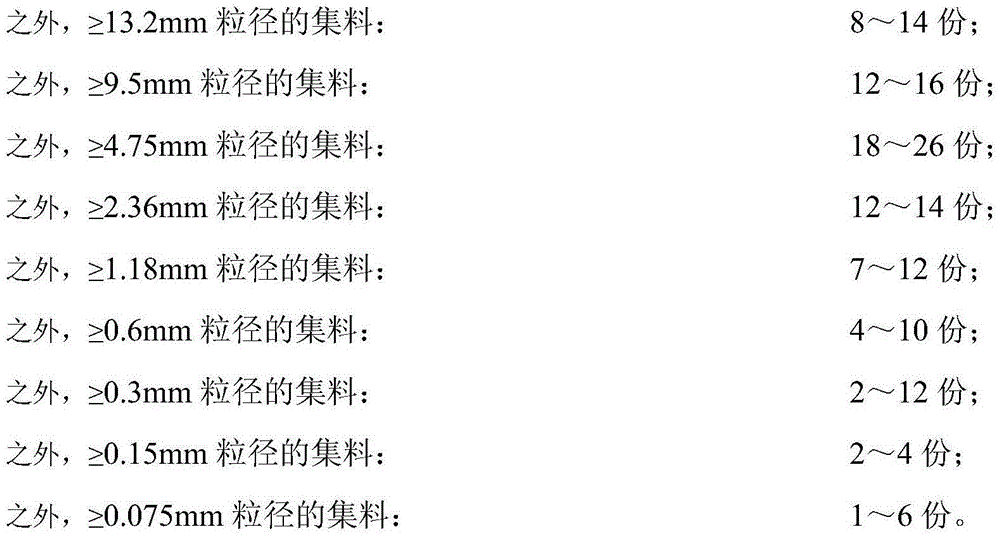

[0043] (2) Use aggregates with a particle size of <0.075mm as mineral powder, sieve the aggregates according to the mass ratio requirements, and use the sieved a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com