Low-temperature pyrolysis method of coal gas for hydrogen production and co-production of LNG (liquefied natural gas)

A low-temperature pyrolysis and coal gas technology, applied in hydrogen separation, gas fuel, petroleum industry, etc., can solve the problems of high comprehensive investment and increased investment cost, achieve low energy consumption, reduce investment and operating costs, and meet the demand for hydrogen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

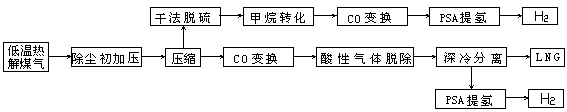

[0027] The method of low-temperature pyrolysis coal gas hydrogen production and co-production of LNG in this embodiment is to use a certain low-temperature pyrolysis gas, whose composition is shown in Table 1, and the designed gas treatment capacity is 2.0×10 5 N m 3 / h, the target hydrogen demand is 1.02×10 5 N m 3 / h, according to which the gas volume percentage of the two parts is divided into 12%: 88%, and the heat section is carried out according to their respective processes. After the raw gas is dedusted, initially pressurized (using a screw compressor) and compressed (using a reciprocating compressor), a part (12%) is desulfurized by a dry method, and then sent to the PSA after passing through a methane conversion device and a carbon monoxide conversion device. The hydrogen extraction device extracts hydrogen. The other part (88%) is sent to the conversion device for carbon monoxide conversion, then eluted with low-temperature methanol to remove acid gas, a...

Embodiment 2

[0031] The method of low-temperature pyrolysis coal gas hydrogen production and co-production of LNG in this embodiment is to use a certain low-temperature pyrolysis gas, whose composition is shown in Table 2, and the designed gas processing capacity is 2.0×10 5 N m 3 / h, the target hydrogen demand is 1.48×10 5 N m 3 / h, according to which the gas volume percentage of the two parts is divided into 34%: 66%. The gas is firstly dedusted, initially pressurized (using a screw compressor) and compressed (using a reciprocating compressor), and a part (34%) is desulfurized by a dry process, and then sent to the PSA after passing through a methane conversion device and a carbon monoxide conversion device. The hydrogen plant extracts hydrogen. The other part (66%) is sent to the conversion device for carbon monoxide conversion, then eluted with low-temperature methanol to remove acid gas, and then sent to the cryogenic separation device for separation to produce hydrogen an...

Embodiment 3

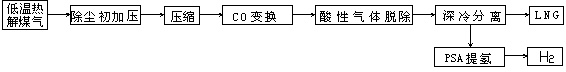

[0035] see figure 2 , the method of low-temperature pyrolysis coal gas hydrogen production and co-production of LNG in this embodiment is to use a certain low-temperature pyrolysis gas, the composition of which is shown in Table 3, and the designed gas treatment capacity is 2.0×10 5 N m 3 / h, the target hydrogen demand is 7.42×10 4 N m 3 / h, according to this, there is no need to divide the gas into two parts, and the gas is directly dedusted, initially pressurized (using a screw compressor) and compressed (using a reciprocating compressor), and then sent to the conversion device for carbon monoxide conversion. Elute the acid gas with low-temperature methanol, and then send it to the cryogenic separation device for separation to produce hydrogen and LNG products, and send the hydrogen separated by cryogenic separation to the PSA hydrogen extraction device for further purification. Among the obtained products, the purity of the hydrogen product reaches 99.99%, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com