Water-fire resistant ventilation air methane mixing device

A water-sealing fire-stop and wind-gas technology, applied in mixers, mixing methods, fluid mixers, etc., can solve the problems of wire mesh blockage, dust blockage, and increased airflow pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

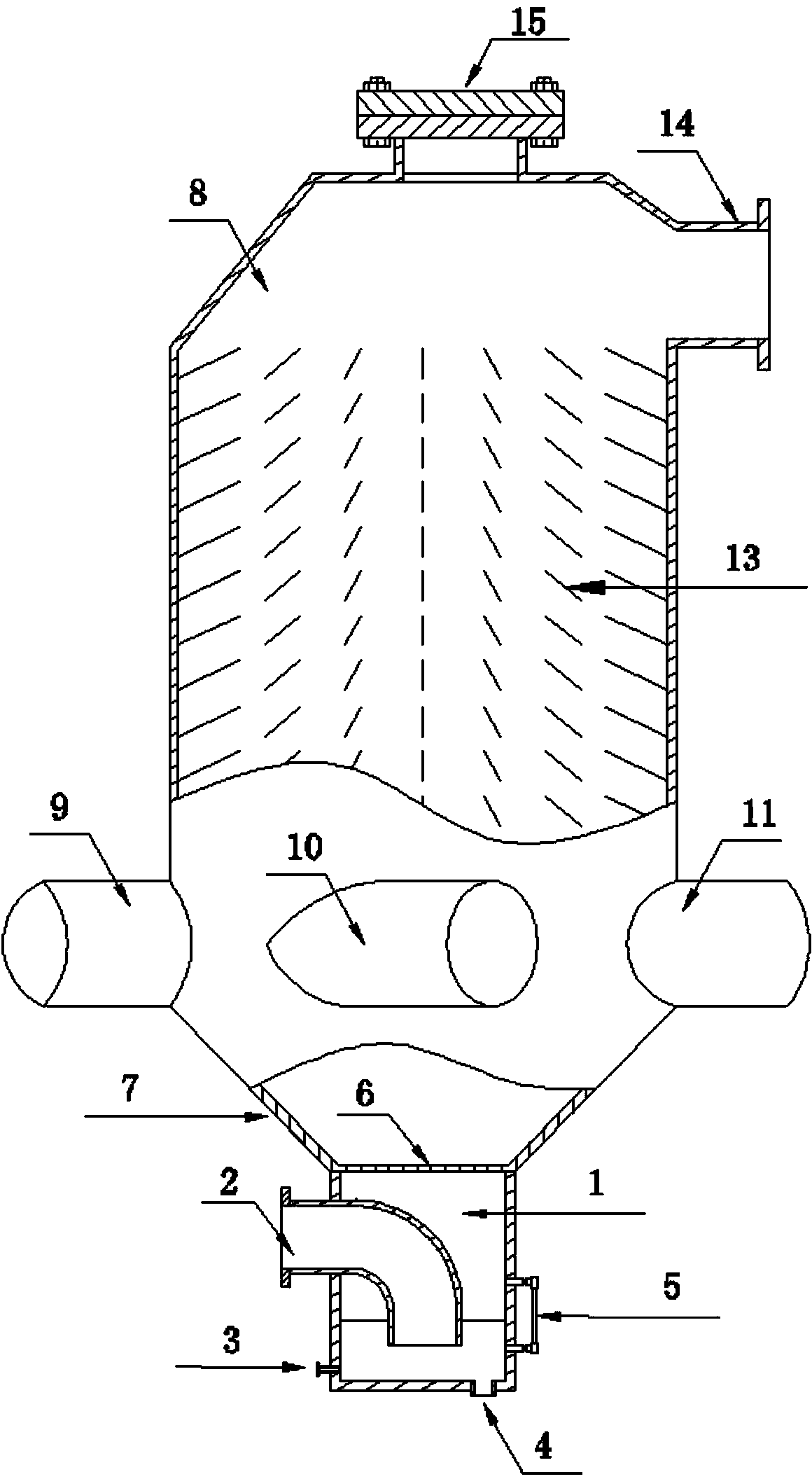

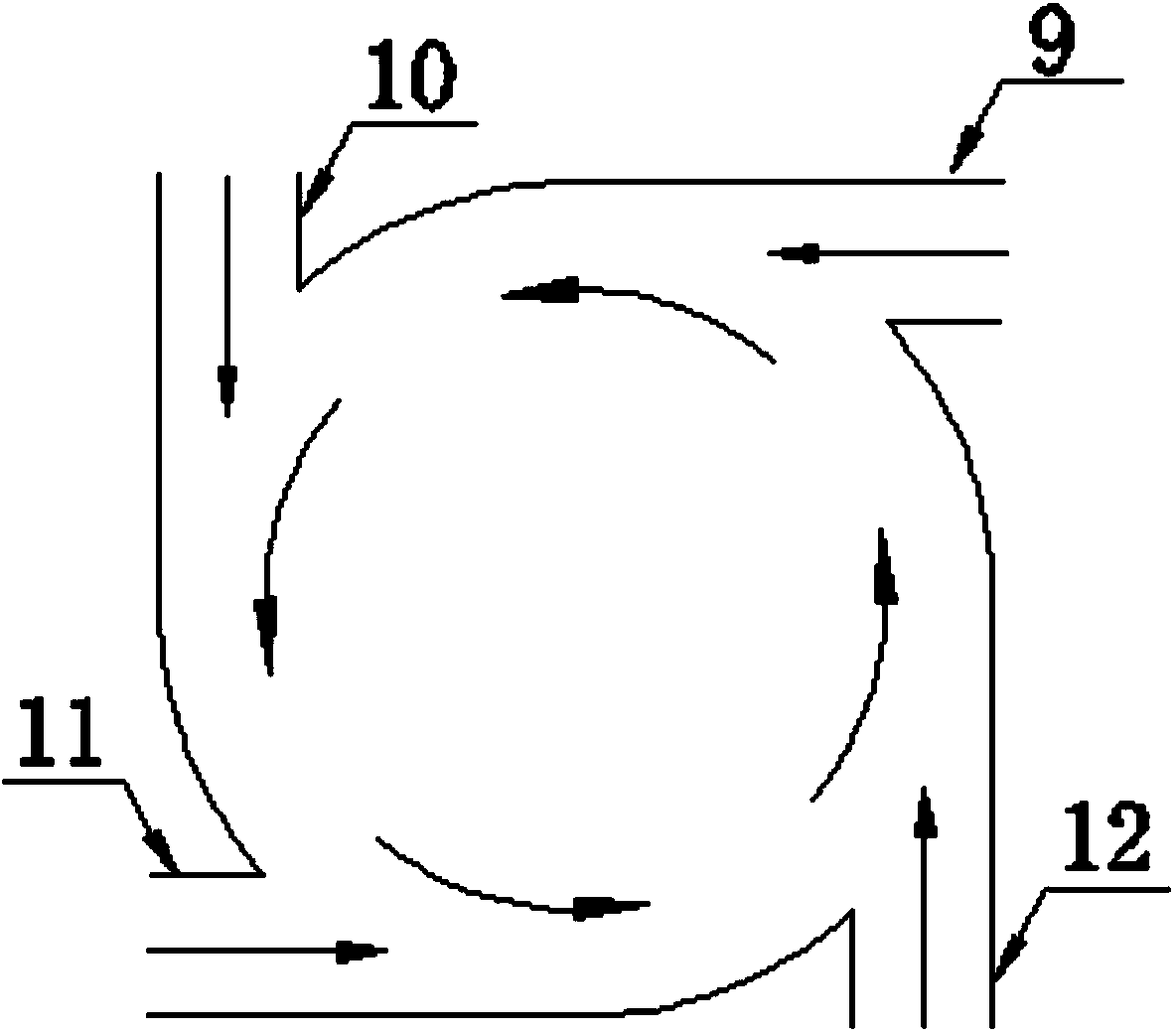

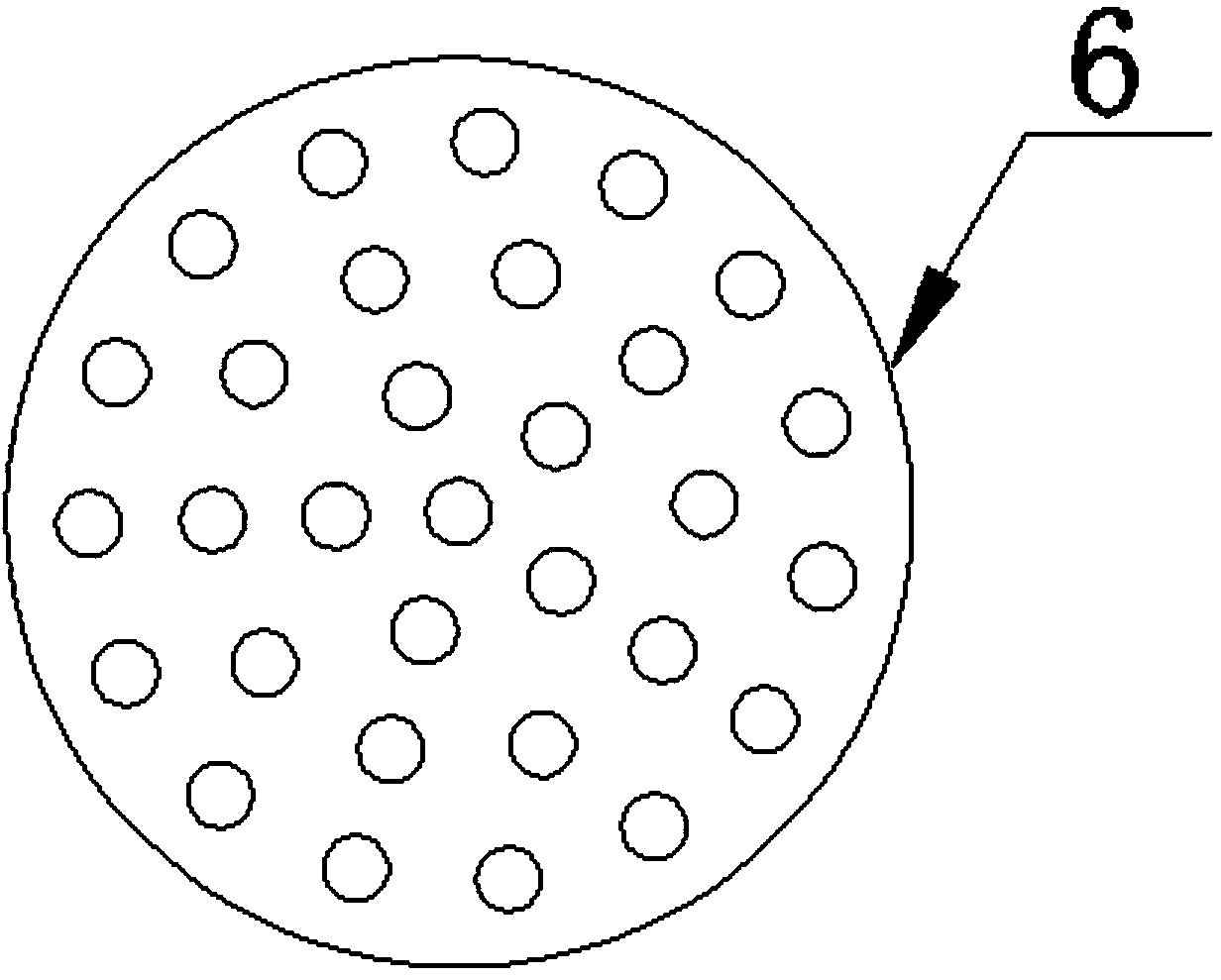

[0022] Such as figure 1 As shown, a water-sealed fire-stop type exhaust gas mixing device includes a water storage cylinder 1 and a mixing cylinder 8 connected to the water storage cylinder, and the water storage cylinder is arranged on the side of the mixing cylinder At the bottom, the water storage cylinder is provided with a low-concentration gas inlet pipe 2, the nozzle of the low-concentration gas (5%-30%) inlet pipe is submerged under the liquid surface, and the lower part of the mixing cylinder is provided with at least two According to the exhaust air inlet pipe, the upper part of the blending cylinder is provided with an air outlet 14, and the exhaust air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com