Flue-cured tobacco steam resurgence device and working method thereof

A steaming and flue-cured tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems that commercial characteristics cannot be fully displayed, affect the income of tobacco companies and tobacco farmers, and affect the work enthusiasm of grading personnel, etc., and achieve good moisture resurgence effect and tobacco leaf moisture resurgence Uniform, structurally simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

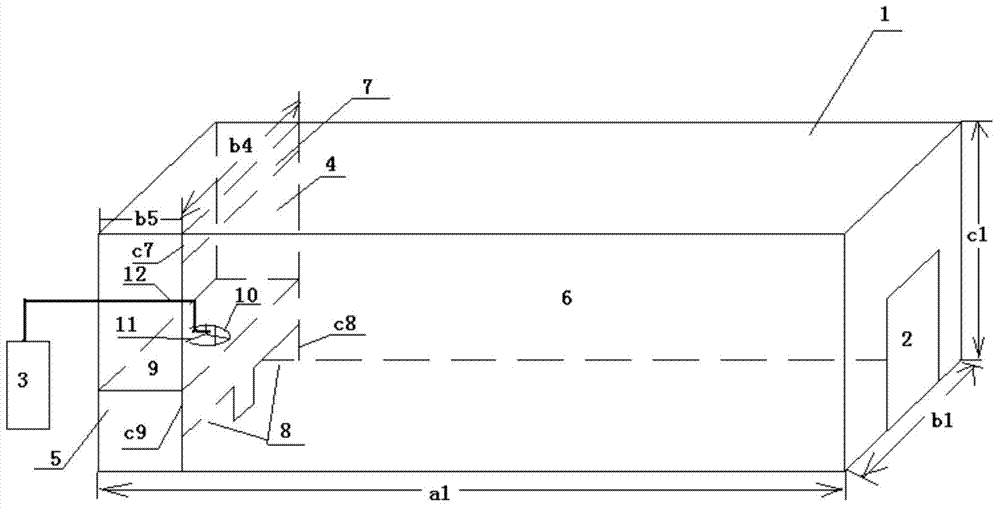

[0049]A flue-cured tobacco vapor resurfacing device, comprising a device casing 1, a loading and unloading door 2 is arranged at one end of the casing 1, and a high-temperature and high-pressure steam generating device 3 is arranged outside the other end of the casing; inside the casing 1 A partition 4 is provided, and the partition 4 divides the shell into a steam chamber 5 and a smoke chamber 6, and an air return port 7 is arranged between the upper end of the partition 4 and the top end of the shell 1, and the partition An air outlet 8 is provided between the bottom end of the plate 4 and the bottom of the housing 1;

[0050] In the steam chamber 5, a fan partition 9 is arranged between the air return port 7 and the air outlet 8, and a mounting hole 10 is arranged on the fan partition, and a high-pressure Fan 11, the wind direction of the high-pressure fan 11 is: blowing from top to bottom; above the high-pressure fan 11 is provided with an outlet pipe 12 of the high-temper...

Embodiment 2

[0052] A kind of working method of flue-cured tobacco steam moisture resurfacing device as described in embodiment 1, comprises steps as follows:

[0053] (1) installing a moisture meter in the shell of the flue-cured tobacco steam resurfacing device;

[0054] (2) Send the tobacco leaves to be rehydrated into the casing with the tip facing upward and the petiole downward, and discharge it close to the partition; the bottom of the tobacco leaf is overhead, and its overhead height is the same as the height of the air outlet adapt;

[0055] (3) Turn on the high-pressure fan and the high-temperature and high-pressure steam generating device, and the high-temperature and high-pressure steam enters the bottom of the tobacco leaves along the air outlet pipe, the fan, and the air outlet, and finally passes through the gaps between the tobacco leaves to achieve moisture resurgence on the tobacco leaves;

[0056] (4) Under the action of the high-pressure fan, the airflow in the casing ...

Embodiment 3

[0058] A kind of flue-cured tobacco steam moistening device as described in embodiment 1, its difference is,

[0059] A cigarette loading trolley 13 is also arranged in the smoke loading room, and the cigarette loading trolley 13 includes multi-layer mesh cages 14, and a cage door 15 is arranged on one side of each layer of mesh cages.

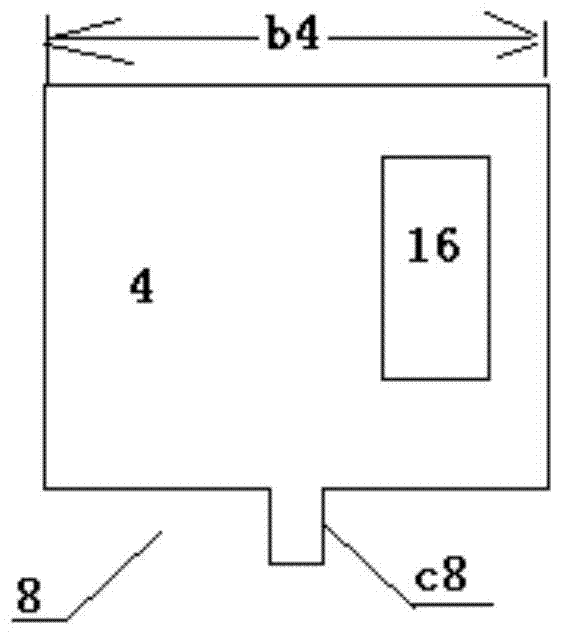

[0060] The length a1 of the shell 1 is 700-750cm, the width b1 is 270-280cm, and the height c1 is 300-310cm; the width b4 of the partition 4 is adapted to the width b1 of the shell, and the bottom of the partition 4 The height c8 of the air outlet at the end is adapted to the distance from the bottom cage of the cigarette loading trolley 13 to the ground; the height c7 of the return air outlet 7 arranged at the top of the partition plate 4 is 40-50cm; the steam chamber 5 The width b5 is 100-105cm.

[0061] A maintenance door 16 for maintenance personnel to enter and exit is provided on the partition 4 .

[0062] The length a13 of the cigaret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Installation height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com