Transformer rectangular pipe opening blocking plate sealing structure and sealing method

A technology of sealing structure and transformer, which is applied in transformer/inductor parts, engine sealing, electrical components, etc. It can solve the problems of time-consuming and labor-intensive turning of the wrench, consumption of gas cutting fuel, and consumption of raw materials, so as to achieve good sealing effect and reduce labor Strength, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

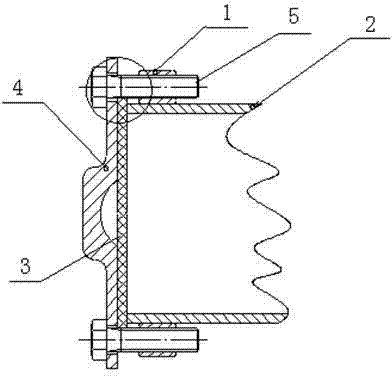

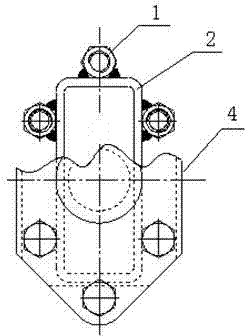

[0017] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

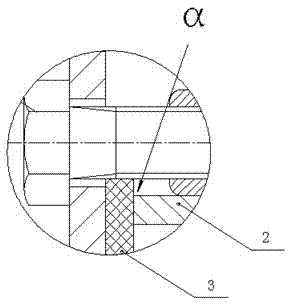

[0018] A sealing structure of a transformer rectangular nozzle blocking plate, including a hexagonal nut 1, a rectangular steel pipe 2, a rubber backing plate 3, a blocking plate 4 and fastening bolts 5, and several hexagonal The nut, the blocking plate is hexagonal, and is connected with the rectangular steel pipe through fastening bolts and hexagonal nuts. There is a rubber backing plate between the blocking plate and the connected rectangular steel pipe. The rubber backing plate is rectangular and its size matches the end face of the rectangular steel pipe. .

[0019] The rubber pad is provided with mounting holes.

[0020] A method for sealing a rectangular tube opening blocking plate of a transformer, comprising the following process steps: ① Fix several hexagonal nuts on the outer sides of the four tube walls at the rectangular steel tube opening, the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com