Method for manufacturing shield tunnel longitudinal prestressing concrete lining segment

A technology for lining segment and shield tunnel, which is applied in the engineering field to achieve the effects of convenient construction, high economic benefit and reduction of longitudinal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0037] The invention discloses a method for preparing a longitudinal prestressed concrete lining segment of a shield tunnel, which comprises the following steps:

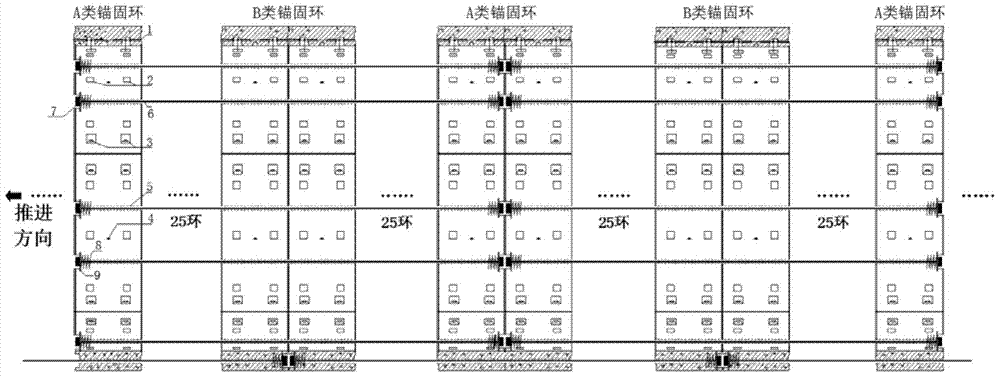

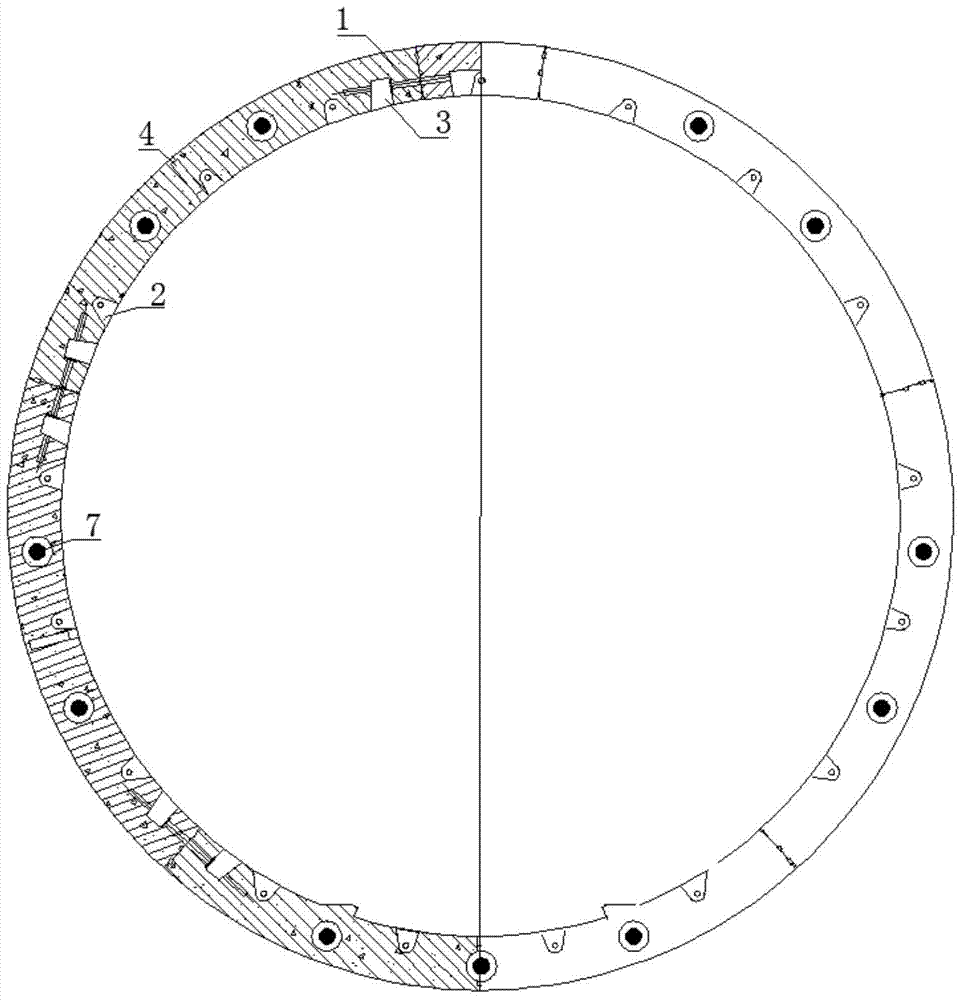

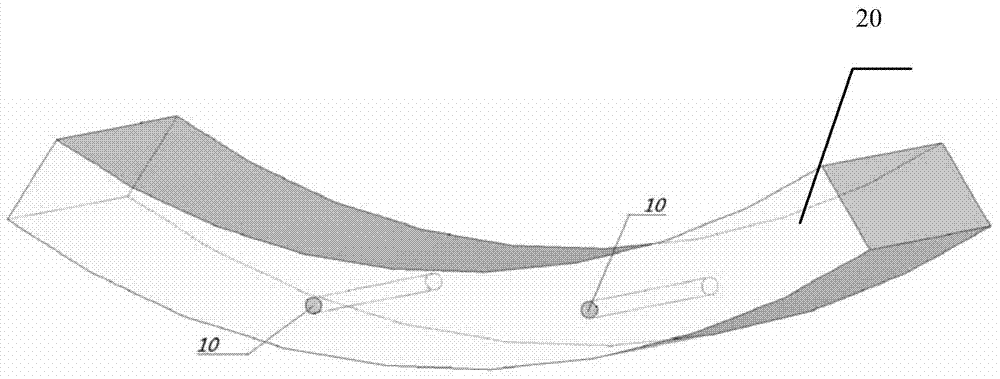

[0038] (1) Permanently embed hole-making devices at predetermined positions on the connecting block, standard block, and arch bottom segment of the lining ring in each group of circulation intervals to make tunnels, and the tunnels on adjacent segments are connected vertically to each other to form multiple tunnels. Preset channels running longitudinally through the circulation area;

[0039] (2) The prestressed steel strands are respectively inserted in multiple preset channels, and when a cycle section is assembled, it is stretched and anchored to form an overall structure.

[0040] The preparation method of the longitudinal prestressed concrete lining segment of the shield tunnel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com