Connector for connecting assembly type steel plate shearing wall and steel beam

A technology of steel plate shear walls and connectors, which is applied in the direction of construction and building structure, etc., can solve the problems of easy eccentricity and out-of-plane buckling of steel plate shear walls under stress, saving installation time and improving Engineering efficiency, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

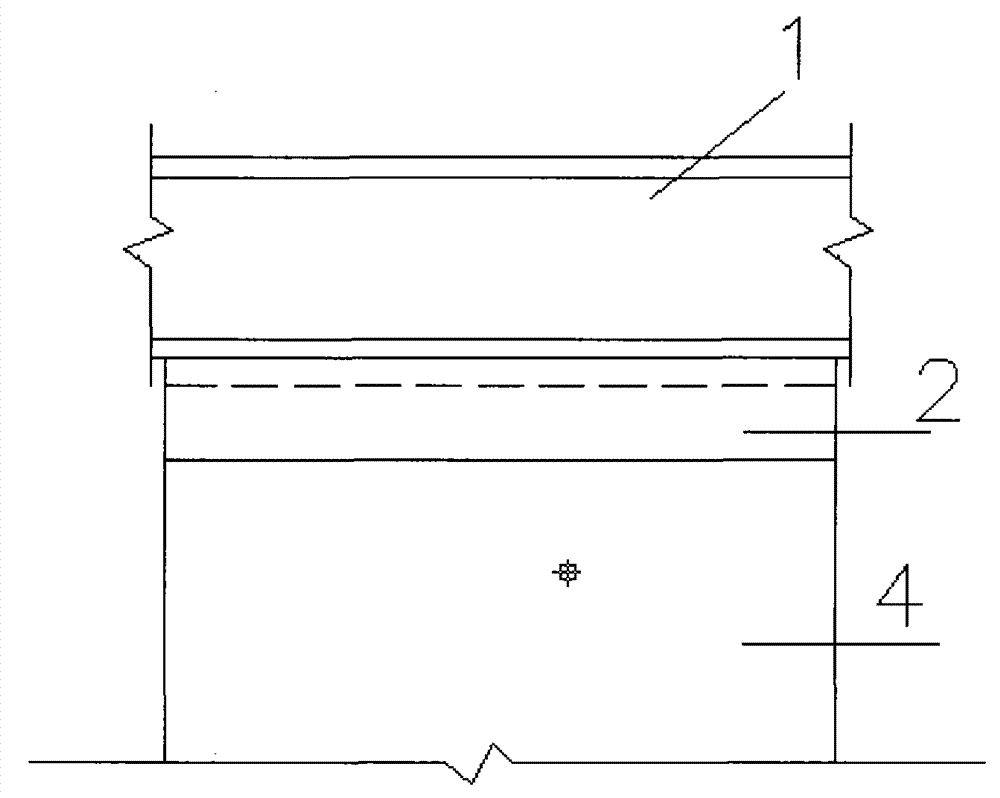

[0027] As shown in the figure, a connector for the connection between a prefabricated steel plate shear wall and a steel beam is characterized in that it includes a steel frame beam (1), a first double fishplate connector (2), and a second double fishplate connector (3), the steel plate shear wall (4), the steel plate shear wall (4) is located directly below the steel frame beam (1), the steel frame beam (1) and the steel plate shear wall (4) A first double fishplate connector (2) and a second double fishplate connector (3) are arranged symmetrically on both sides of the contact part, and the first double fishplate connector (2) and the second double fishplate connector (3) and the steel frame beam (1) have butt welds (5), the first double fishplate connector (2) and the second double fishplate connector (3) and the steel plate shear wall (4) The joints have fillet welds (6). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com