Plasmid, recombinant engineering bacteria and method for preparing hyaluronic acid with uniform molecular weight

A technology of recombinant engineering bacteria and hyaluronic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, recombinant DNA technology, etc., can solve problems such as unrealization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

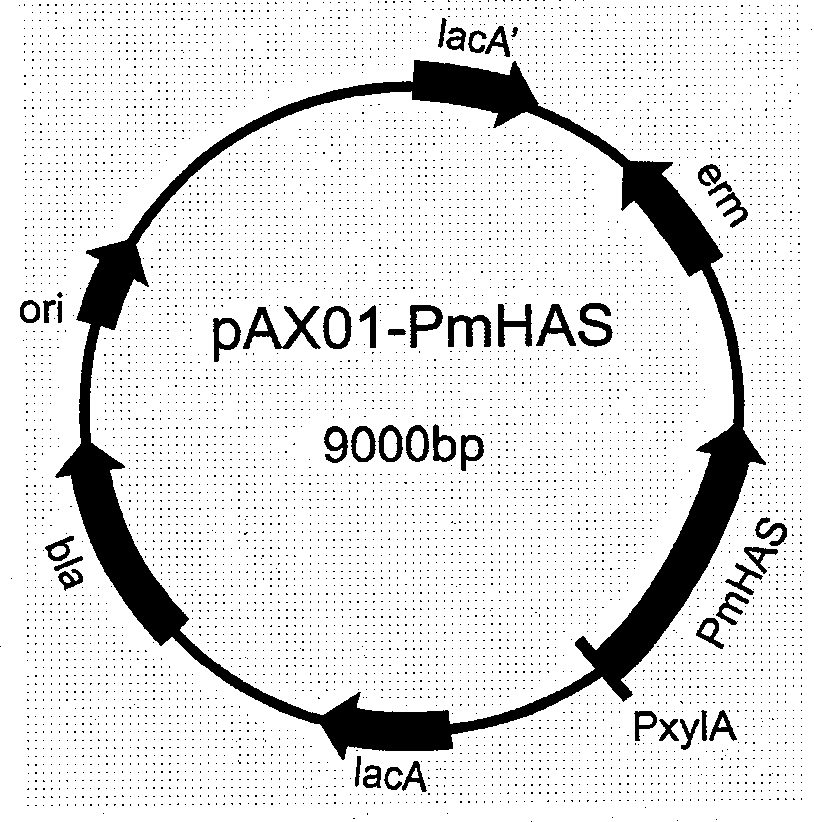

[0085] Example 1: Cloning of hyaluronan synthase gene and construction of integrated expression vector

[0086] (1) Cloning of Pasteurella multocida Hyaluronate synthase gene

[0087] Genomic DNA of Pasteurella multocida (Pasteurella multocida P-1059ATCC#15742) was extracted using the Tiangen Bacteria Genomic DNA Extraction Kit, and a pair of primers were designed to perform PCR reaction using the extracted Genomic DNA of Pasteurella multocida as a template , the specific reaction conditions were pre-denaturation at 94°C for 5 minutes, followed by 30 cycles of 94°C for 1 minute, 48°C for 1 minute, and 72°C for 2 minutes and 30 seconds, and finally 72°C for 8 minutes. The sequence of a pair of primers designed is as follows:

[0088] 5'-CGACTAGTATGAATACATTATCACAAGCAATAAAAGC-3' (with a Spe I restriction site at the 5' end, ACTAGT), primer SEQ NO.12.

[0089]5'-CGGGATCCCTAAATATCTTTTAAGATATCAATCT-3' (with a BamH I restriction site at the 5' end, GGATCC), primer SEQ NO.13.

[00...

Embodiment 2

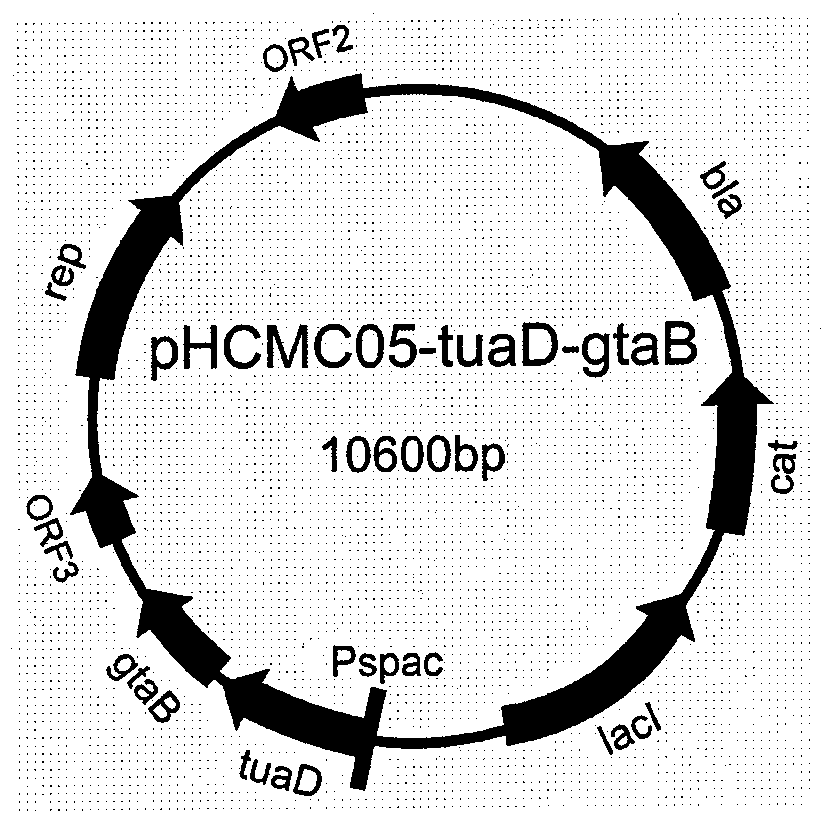

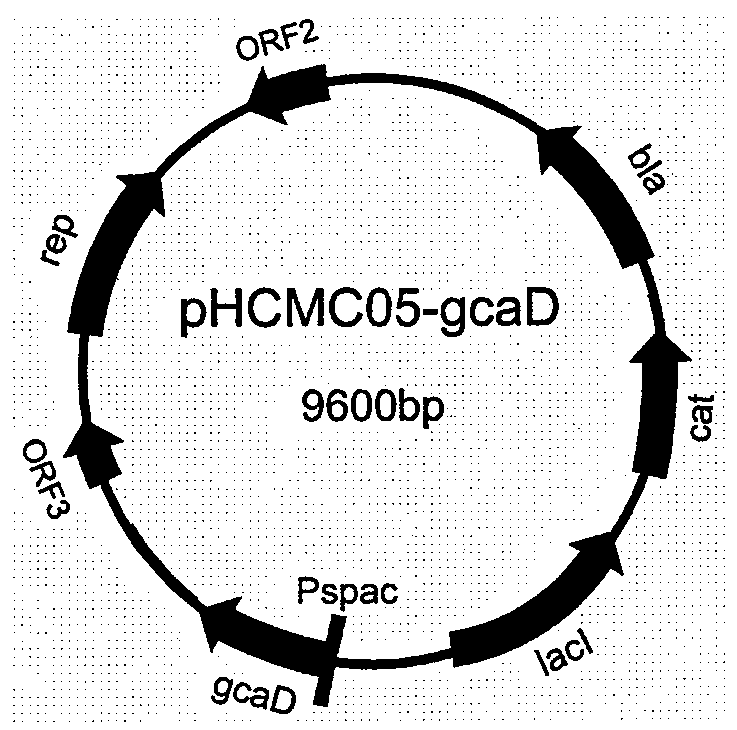

[0093] Example 2: Cloning of enzyme genes related to hyaluronic acid precursor synthesis and construction of episomal stringent expression vectors

[0094] (1) Cloning from Bacillus subtilis UDP-glucose dehydrogenase gene (UDP-Glucose dehydrogenasegene)

[0095] Genomic DNA of Bacillus subtilis (Bacillus subtilis subsp.subtilis168) was extracted using the Tiangen Bacteria Genomic DNA Extraction Kit, a pair of primers were designed, and the extracted Bacillus subtilis genomic DNA was used as a template for PCR reaction. The specific reaction conditions were pre-denaturation at 94°C for 5 Minutes, followed by 30 cycles at 94°C for 1 minute, 48°C for 1 minute, and 72°C for 1 minute and 30 seconds, and finally according to the program of 72°C for 8 minutes. The sequence of a pair of primers designed is as follows:

[0096] 5'-CGGGATCCGGAGAGGGTTGAGCGCTGTGAA-3' (with a BamH I restriction site at the 5' end, GGATCC), primer SEQ NO.14.

[0097] 5'-GCTCTAGATTATAAATTGACGCTTCCCAAGTCTTT...

Embodiment 3

[0120] Example 3: The expression vectors constructed in Examples 1 and 2 were respectively transformed into Bacillus subtilis host cells to obtain recombinant engineered strains, and several homogeneous hyaluronic acids with different molecular weights were prepared by fermentation.

[0121] This example describes the transformation of the expression vectors constructed in Examples 1 and 2 into Bacillus subtilis host cells by preparing competent methods to obtain recombinant engineering strains, and prepare several homogeneous hyaluronic acids with different molecular weights by fermentation .

[0122] (1) The constructed integrated expression vector pAX01-PmHAS was transformed into Bacillus subtilis cells to obtain the recombinant engineering strain B. subtilis (pAX01-PmHAS).

[0123] Prepare the competent state of Bacillus subtilis according to the following method: Streak Bacillus subtilis on the LB plate to obtain a single colony, then inoculate the single colony into 3mL li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com