Olefin isomerization catalyst passivation treatment method

A technology for olefin isomerization and passivation treatment, which is applied in the direction of physical/chemical process catalysts, catalyst protection, isomerization hydrocarbon production, etc. It can solve the problem that the output of isobutene cannot meet the needs of the production of etherification units, so as to improve the output efficiency and selectivity, inhibition of polymerization, and promotion of isomerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

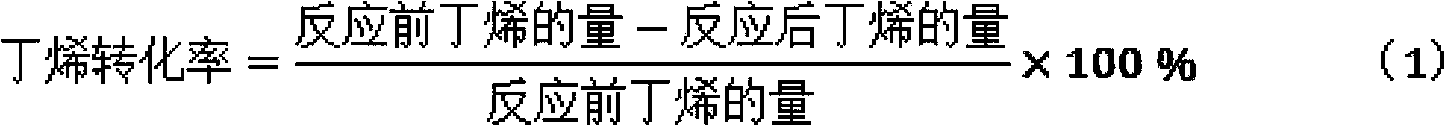

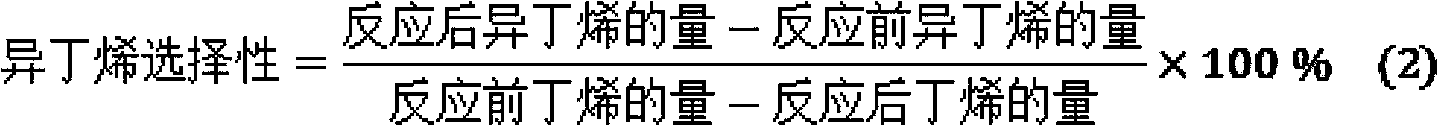

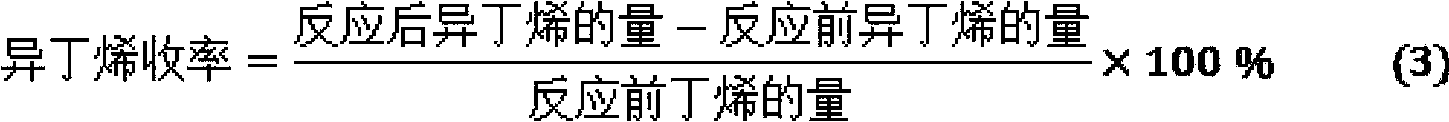

Examples

Embodiment 1

[0029] Dry mix HZSM-35 molecular sieve and pseudo-boehmite, then drop nitric acid aqueous solution to make extrudable material, wherein the weight ratio of HZSM-35 molecular sieve / pseudo-boehmite is 1:1. The mixed materials were extruded into strips with a diameter of 2mm, dried at 120°C for 2 hours, and calcined at 540°C for 4 hours to obtain HZSM-35 acidic molecular sieve catalyst.

Embodiment 2

[0031] The catalyst prepared in Example 1 was loaded into a fixed bed reaction evaluation device, and under the conditions of a temperature of 320° C. and a pressure of 0.15 MPa, the -1 The mass space velocity is passed into the heavy component of n-butene isomerization process by-product (i.e. passivating agent, mainly containing 20% by weight of C 5 , 10 wt% C 6 , 65% by weight of C 8 and a small amount of C 7 and C 9 , where C 5 、C 6 、C 7 、C 8 、C 9 Respectively represent hydrocarbon compounds containing 5, 6, 7, 8, 9 carbon atoms; the passivating agent used below has the same composition) contact with the catalyst and passivate for 5 hours. Stop the feed of passivating agent, calculated as n-butene for 1.0h -1 After the mass space velocity is passed into ether, mixed carbon four (containing 43.93% by weight of n-butene, 9.82% by weight of trans-2-butene, 6.16% by weight of cis-2-butene, 2.36% by weight of isobutene, 22.72 weight % of isobutane, 15.02 weight % of...

Embodiment 3

[0033] The specific implementation process is roughly the same as in Example 2, except that the temperature is changed to 350° C., and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com