Mesoporous/macropore hierarchical pore block bilirubin adsorbent material and preparation method thereof

A block material and adsorbent technology, applied in chemical instruments and methods, suction devices, and other chemical processes, can solve problems such as low adsorption capacity, poor adsorption selectivity, and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

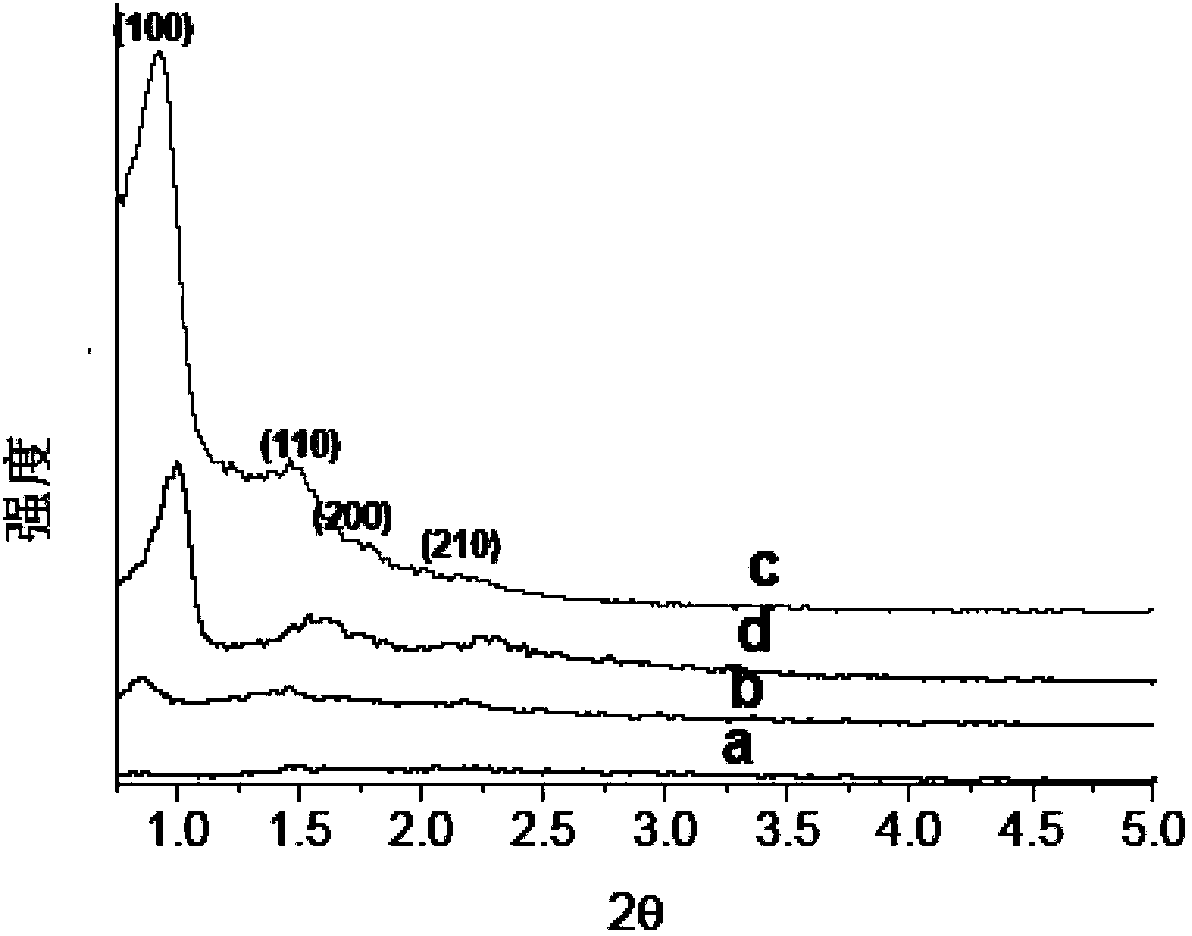

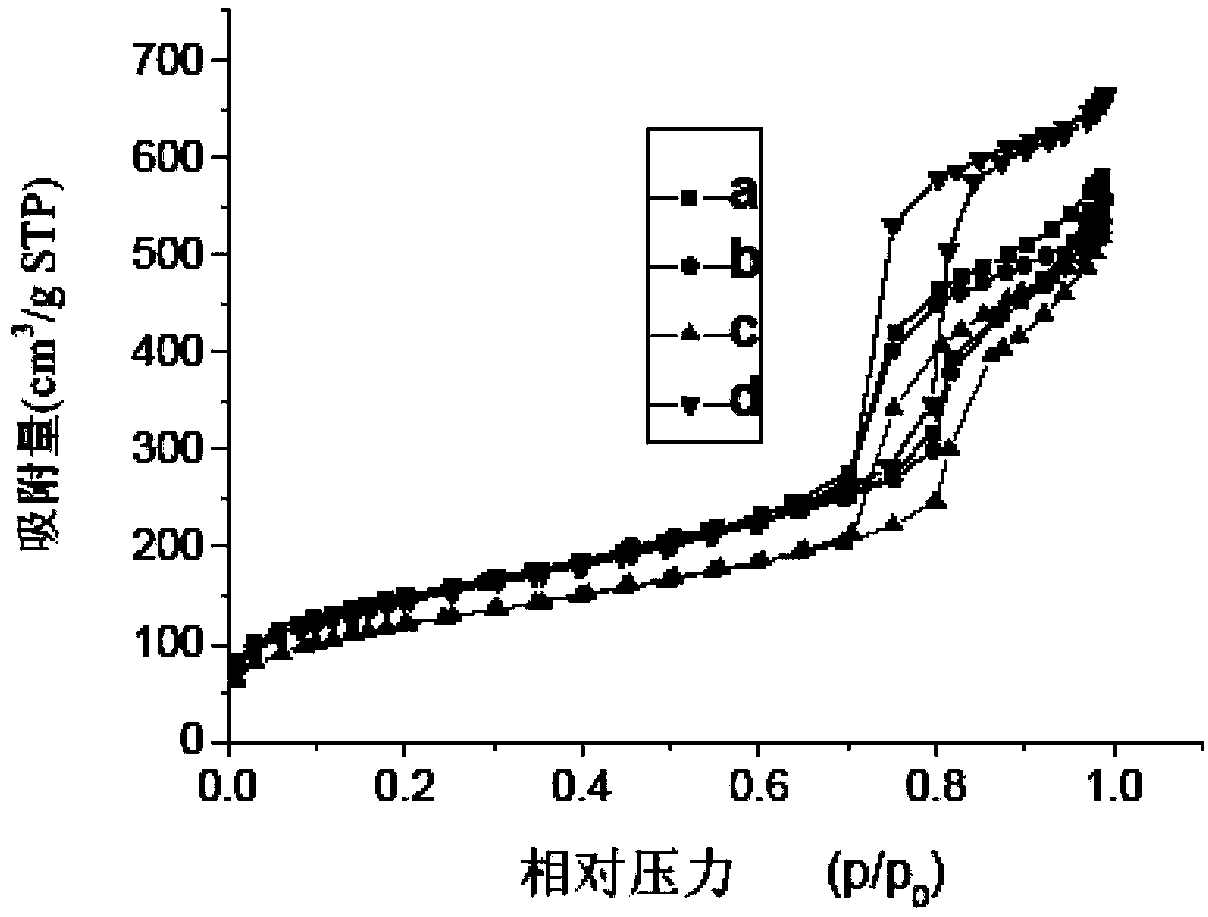

[0075] Weigh a certain amount of P123 into a beaker, then add appropriate amount of hydrochloric acid and water, so that the molar concentration of hydrochloric acid is 1.18M, 1.34M, 1.49M and 1.65M respectively, put the beaker in a 37°C water bath and stir Dissolve P123; after P123 dissolves, add a certain amount of ethyl orthosilicate under strong stirring, so that the molar ratio of the substances in the solution is: SiO 2 :P123:H 2 O=1.00:0.016:180, continue to stir for 5 minutes and immediately transfer the sol to a hydrothermal kettle and place it in a constant temperature oven at 120°C for 24 hours, then wash the obtained block with distilled water and keep it at a constant temperature of 100°C Dry in an oven overnight, and then calcine in a muffle furnace at 550° C. for 6 hours to remove the surfactant P123, so as to obtain each matrix-silica block. It was found that the concentration of hydrochloric acid in the range of 1.18-1.65M can get a complete block ( figure...

Embodiment 5-10

[0081] Weigh a certain amount of P123 into a beaker, add appropriate amount of hydrochloric acid and water to make the molar concentration of hydrochloric acid 1.49M, put the beaker in a 37°C water bath and stir to dissolve the P123; Add a certain amount of ethyl orthosilicate under strong stirring, so that the molar ratio of the substances in the solution is: SiO 2 :P123:HCl:H 2 O=1.00:0.016:5.00:180, after continuing to stir for 5 minutes, immediately transfer the sol into a hydrothermal kettle and place it in a constant temperature oven for 24 hours. The temperatures of each constant temperature oven are respectively: 110, 120, 130, 140, 150 and 170°C, and then the obtained block was washed with distilled water and dried overnight in a constant temperature oven at 100°C, and then calcined in a muffle furnace at 550°C for 6 hours to remove the surfactant P123 to obtain each precursor - Silica bulk. It was found that hydrothermal temperatures in the range of 110–170°C yield...

Embodiment 11-21

[0088] Weigh a certain amount of P123 into a beaker, add appropriate amount of hydrochloric acid and water to make the molar concentration of hydrochloric acid 1.49M, put the beaker in a 37°C water bath and stir to dissolve the P123; Add a certain amount of ethyl orthosilicate under strong stirring, so that the molar ratio of the substances in the solution is: SiO 2 :P123:HCl:H 2 O=1.00:0.016:5.00:180, continue to stir for 5 minutes and immediately transfer the sol into a hydrothermal kettle and place it in a constant temperature oven at 120°C for 2 hours and 50 minutes, 5 hours and 20 minutes, and 7 hours and 50 minutes , 10 hours and 20 minutes, 11 hours and 30 minutes, 13 hours, 15 hours and 45 minutes, 18 hours and 30 minutes, 21 hours and 20 minutes, 22 hours and 20 minutes and 24 hours, then the resulting block was washed with distilled water and heated at 100°C Dry in a constant temperature oven overnight, and then calcinate in a muffle furnace at 550° C. for 6 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com