Attapulgite-contaiing composite nanofiltration membrane and making method thereof

A technology of composite nanofiltration membrane and attapulgite, which is applied in the field of nanofiltration membrane, can solve the problems of unsatisfactory comprehensive performance of flux and salt interception rate, and achieve simple and easy experimental process, improved water flux and excellent reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

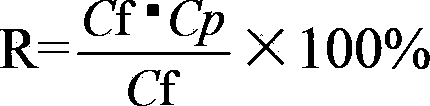

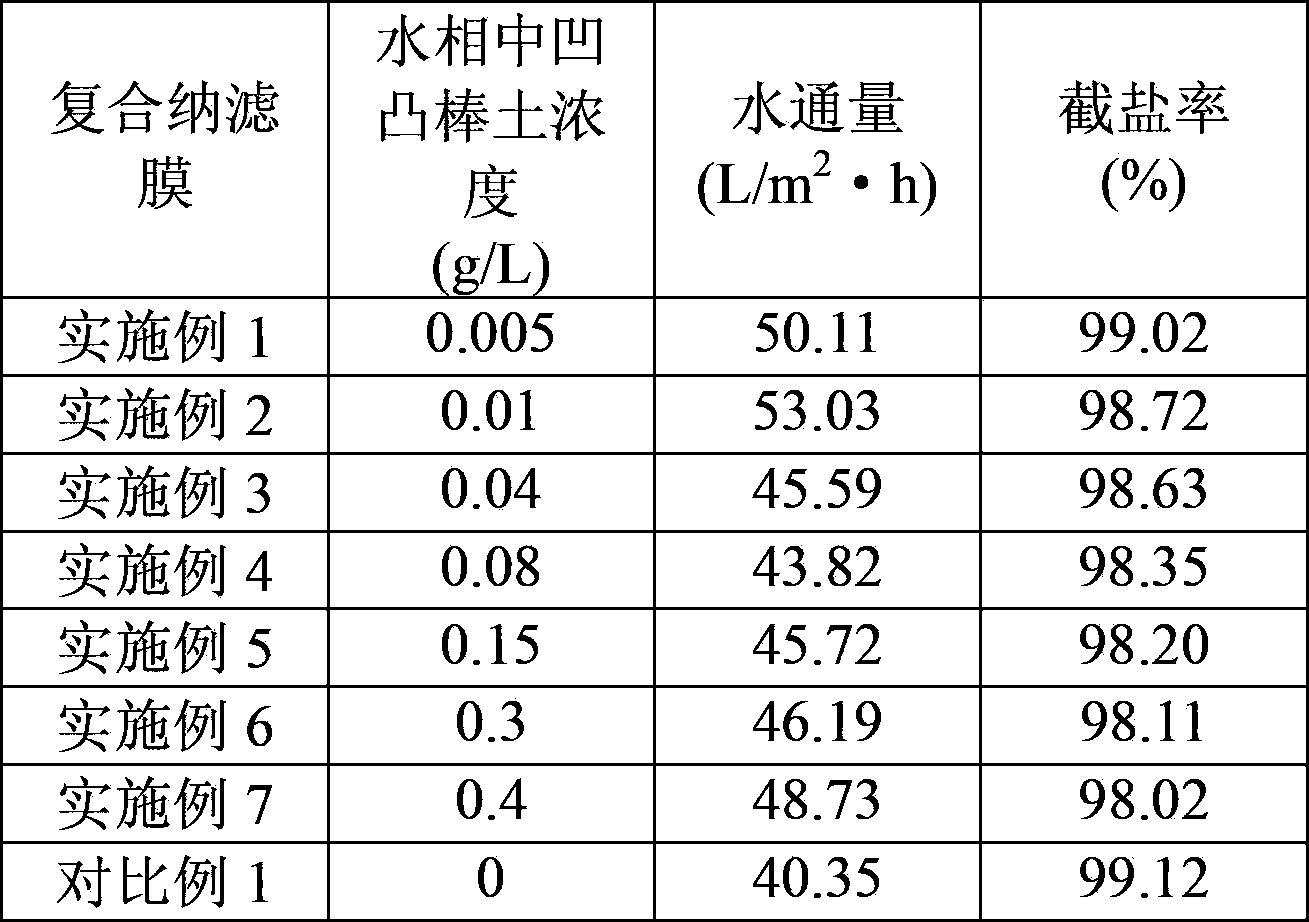

Embodiment 1

[0046] Using a polysulfone porous support membrane, contact with a concentration of 5g / L piperazine (PIP) aqueous phase solution for about 30 seconds, wherein the piperazine aqueous phase solution contains 5g / L triethylamine (TEA), 1g / L decathene Sodium dialkyl sulfate (SDS), 0.005g / L attapulgite, and the polysulfone support membrane soaked by the piperazine aqueous phase solution were removed with a rubber roller to remove excess solution. Then this support film was contacted with n-hexane solution containing 1g / L trimesoyl chloride for 2 minutes; then the formed polyamide layer was air-dried, put into a vacuum oven at 40°C for 8 minutes, and then placed in a Rinse in water at 40° C. for 10 minutes to obtain a polypiperazine amide composite nanofiltration membrane containing attapulgite, and the prepared composite nanofiltration membrane is stored in deionized water. The hollow nanoscale pores of the attapulgite will allow more water molecules to pass through the composite na...

Embodiment 2

[0049] Using a polysulfone porous support membrane, contact with a concentration of 4g / L piperazine (PIP) aqueous phase solution for about 1 minute, wherein the piperazine aqueous phase solution contains 4g / L sodium carbonate (Na 2 CO 3 ), 1g / L sodium dodecylbenzenesulfonate (SBS), 0.01g / L attapulgite, and the polysulfone support membrane soaked by the piperazine aqueous phase solution was removed with a rubber roller to remove excess solution. Then this support membrane was contacted with a cyclohexane solution containing 0.5g / L isophthaloyl chloride for 1 minute; then the formed polyamide layer was air-dried and placed in a vacuum oven at 40°C for 10 minutes , and then rinsed in water at 40° C. for 10 minutes to obtain a polypiperazine amide composite nanofiltration membrane containing attapulgite, and the prepared composite nanofiltration membrane was stored in deionized water. The hollow nanoscale pores of the attapulgite will allow more water molecules to pass through th...

Embodiment 3

[0052] Use a polysulfone porous support membrane to contact with a piperazine (PIP) aqueous phase solution with a concentration of 5g / L for about 1 minute, wherein the piperazine aqueous phase solution contains 5g / L triethylamine (TEA), 1g / L Sodium dialkylbenzenesulfonate (SBS), 0.04g / L attapulgite, and the polysulfone support membrane soaked by the piperazine aqueous phase solution were used to remove excess solution with a rubber roller. Then this supporting film is contacted with ISOPAR E solvent oil (isoparaffin) solution containing 0.5g / L trimesoyl chloride for 50 seconds; then the formed polyamide layer is air-dried and placed in a vacuum at 40°C Keep in an oven for 8 minutes, then rinse in water at 40°C for 10 minutes to obtain a polypiperazine amide composite nanofiltration membrane containing attapulgite, and store the prepared composite nanofiltration membrane in deionized water. The hollow nanoscale pores of the attapulgite will allow more water molecules to pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com