Resin particle aggregate, method for manufacturing same and application of same

一种树脂粒子、聚集体的技术,应用在涂层等方向,能够解决树脂粒子易扬起、难处理、流动性差等问题,达到良好柔焦效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

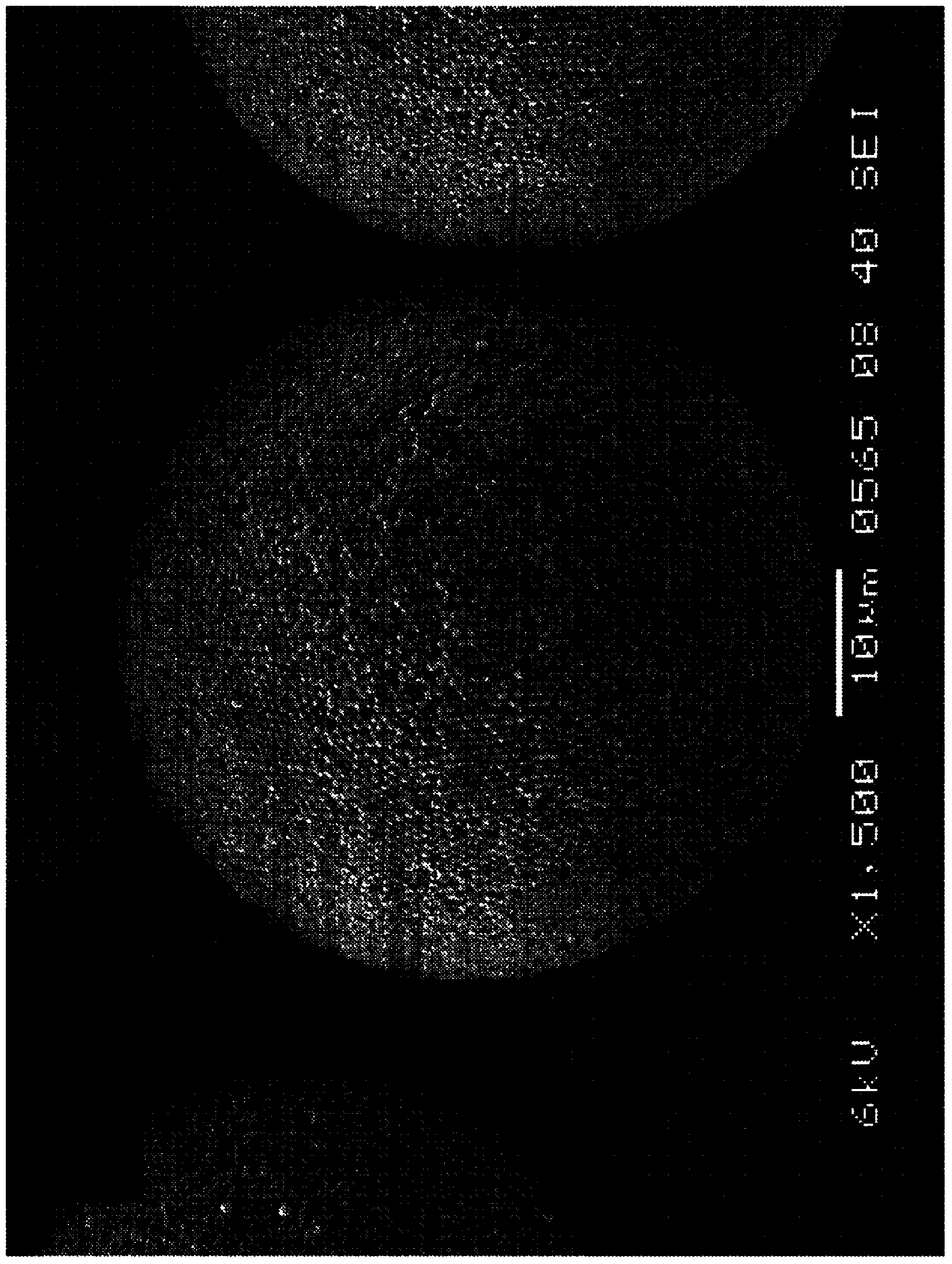

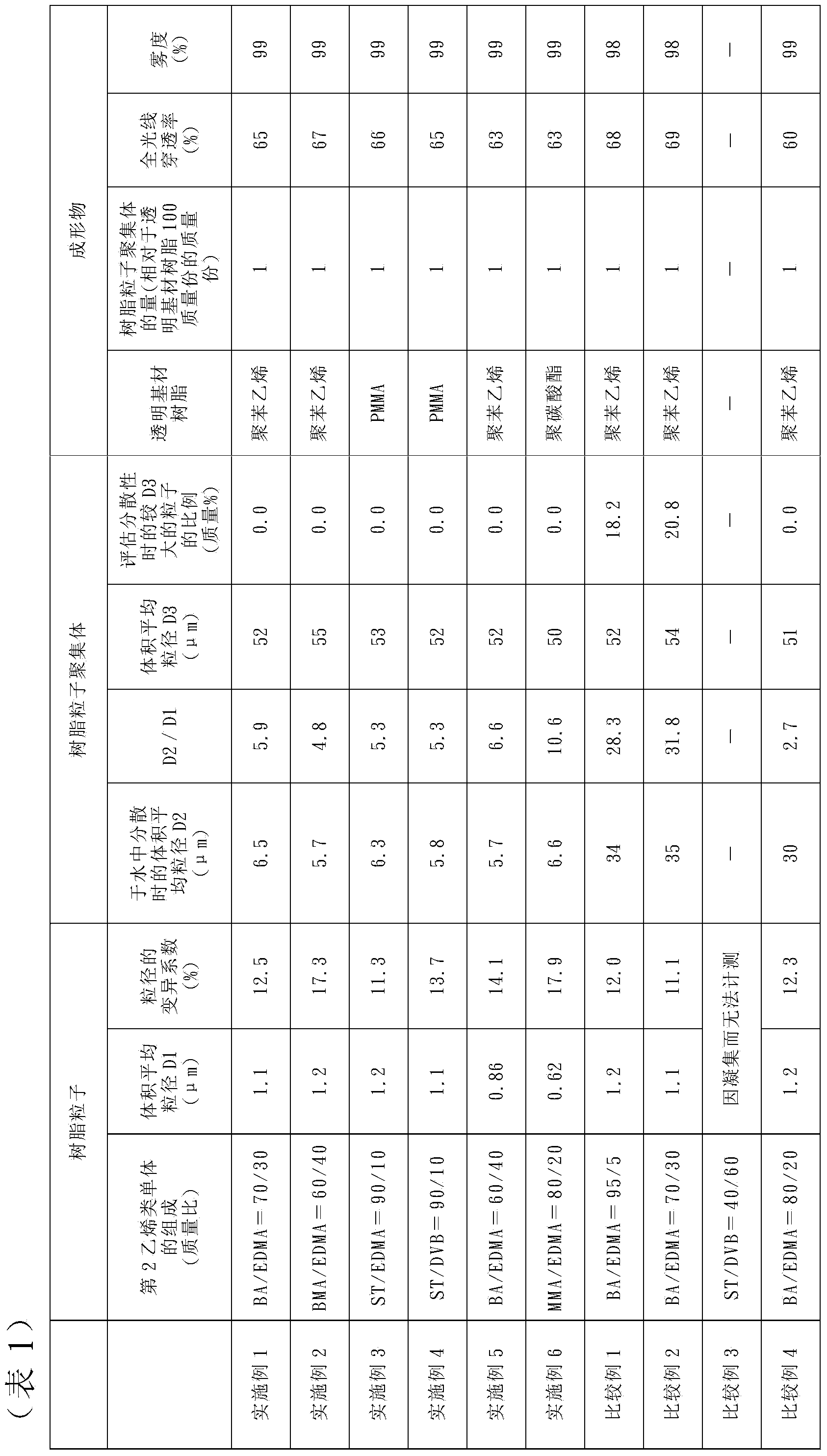

[0049] (resin particle aggregates)

[0050] The resin particle aggregate of the present invention is a resin particle aggregate formed by aggregating (aggregating) a plurality of resin particles (primary particles) composed of polymers of vinyl monomers, and comprising 100 parts by mass of the resin particles With 1 to 5 parts by mass of surfactant, the resin particles are crosslinked by 9 to 50 mass % of crosslinkable monomers relative to the total mass of the resin particles, and the inorganic components in the aggregates of the resin particles The content is 0.5% by mass or less; the ratio of the volume average particle diameter D2 of the particles contained in the dispersion liquid obtained by dispersing the resin particle aggregates in water to the volume average particle diameter D1 of the resin particles D2 / D1 is 15 or less. Here, the volume average particle diameter D2 is measured by the following measurement method: 0.50 g of the resin particle aggregate is mixed wit...

Embodiment )

[0124] Hereinafter, although an Example and a comparative example demonstrate this invention, this invention is not limited to these.

[0125] (Measurement method of mass average molecular weight of seed particles)

[0126] The mass average molecular weight of the seed particles is measured using gel permeation chromatography (GPC; Gel Permeation Chromatography). The measured mass average molecular weight is the equivalent mass average molecular weight of polystyrene (PS). The measurement method is as follows. First, 50 mg of a sample was dissolved in 10 ml of tetrahydrofuran (THF). The resulting solution was filtered through a 0.45 μm non-aqueous chromato disc. The obtained filtrate was analyzed by GPC, and the PS conversion mass average molecular weight was measured. The measurement conditions of GPC are as follows.

[0127] GPC apparatus: Trade name "Gel Permeation Chromatograph HLC-8020" manufactured by TOSOH Co., Ltd.

[0128] Column: 2 pieces of "TSKgel GMH XL-L" (...

Embodiment 1)

[0153] (Manufacture of seed particles)

[0154] First, 250 g of methyl methacrylate as a monofunctional vinylic monomer (first vinylic monomer) and 5 g of n-octyl mercaptan as a chain transfer agent were mixed to prepare 255 g of a monomer mixture. Furthermore, 1.5 g of potassium persulfate as a polymerization initiator was dissolved in 18.5 g of deionized water as an aqueous medium to obtain 20 g of an aqueous potassium persulfate solution.

[0155] Thereafter, 1000 g of deionized water as an aqueous medium was put into a polymerizer equipped with a stirrer and a thermometer, and 255 g of the monomer mixture was supplied to the polymerizer. Then, while stirring the contents of the polymerizer with the stirrer, the air in the polymerizer was replaced with nitrogen, and the internal temperature of the polymerizer was raised to 70°C. Furthermore, after continuing the stirring, while maintaining the internal temperature of the polymerizer at 70° C., 20 g of the aqueous potassium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com