Method for reducing SO2 oxidation rate increase of denitrification catalyst

A denitrification catalyst, SO2 technology, applied in the direction of catalyst activation/preparation, catalyst regeneration/reactivation, chemical instruments and methods, etc., can solve the problems of catalyst performance degradation and achieve the effect of reducing industrial waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

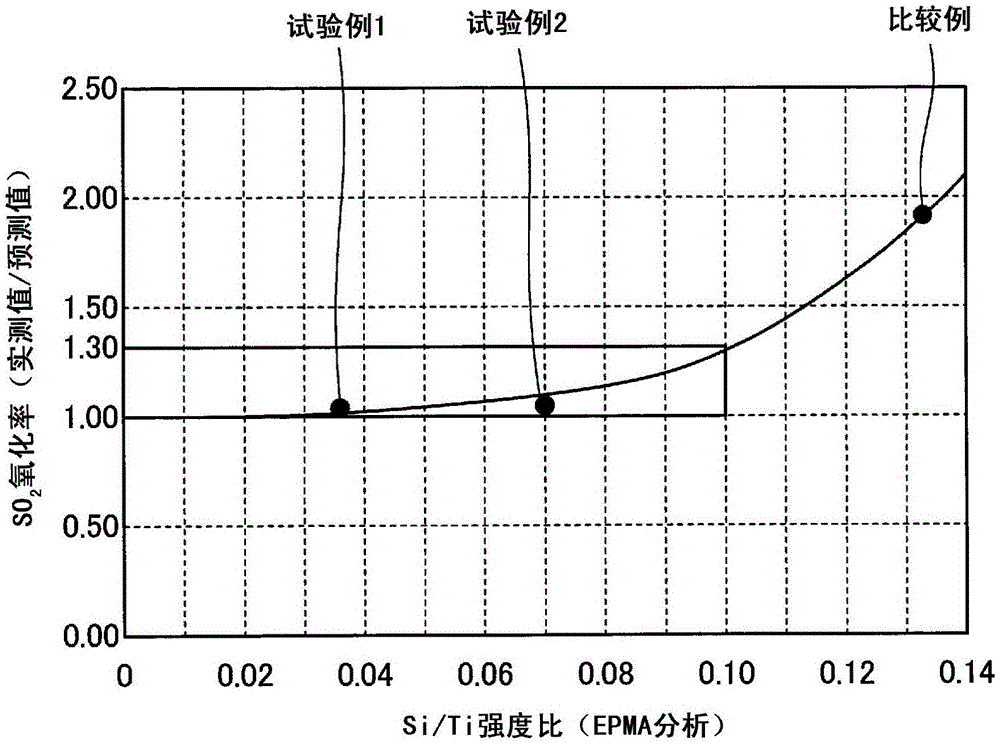

[0026] The catalyst of the present invention is a denitrification catalyst used to remove nitrogen oxides in combustion exhaust gas. 2 When the silica component (silicon compound), which is the inhibitory substance of the increase in the oxidation rate, accumulates on the surface of the catalyst, the silica component already accumulated on the catalyst surface is dissolved to regenerate the catalyst.

[0027] Here, the denitration catalyst regenerated by the present invention has titanium oxide as the main component and contains vanadium, tungsten, molybdenum, etc. as active components, specifically, binary system TiO 2 -WO 3 Catalyst, TiO 2 -MoO 3 Catalyst; or ternary TiO 2 -V 2 o 5 -WO 3 Catalyst, TiO 2 -V 2 o 5 -MoO 3 Catalyst etc.

[0028] Moreover, if the regeneration treatment method of the present invention is shown in the order of steps, the regeneration treatment method of the present invention is a treatment method that undergoes an activation treatment st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com