Array substrate as well as production method thereof and display device

A technology for array substrates and base substrates, applied in the fields of array substrates, array substrates, and display devices, can solve problems such as liquid crystal deflection disorder in display devices, affect the display quality of display devices, and liquid crystal deflection disorder in display devices, etc., to achieve improved Transmittance, avoiding light leakage and color mixing, and improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

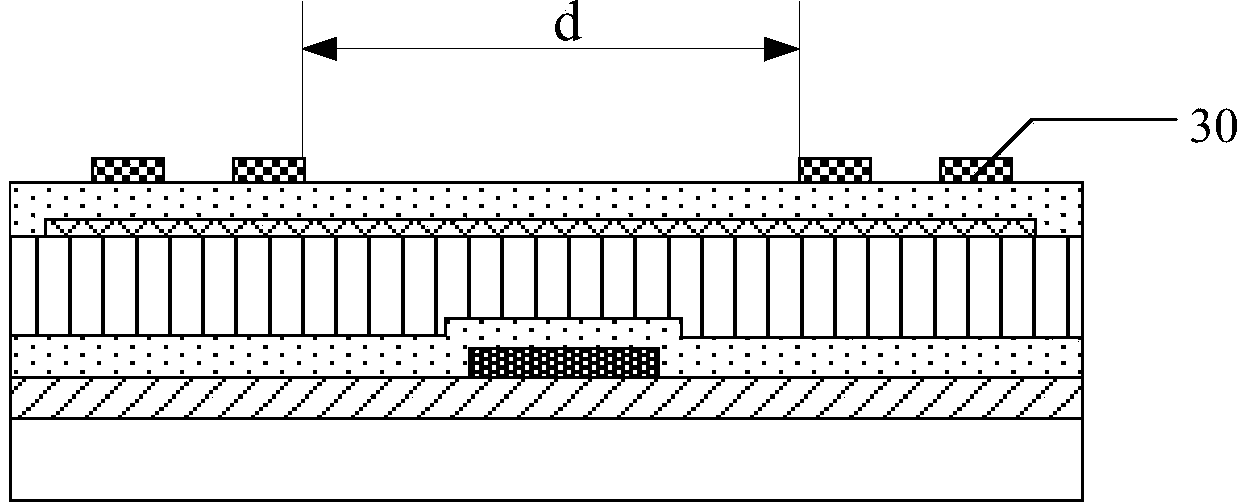

Image

Examples

Embodiment approach 1

[0062] Preferably, the first transparent electrode is in the shape of a slit, and the second transparent electrode is in the shape of a plate.

[0063] Preferably, the second transparent electrode is located in a different layer from the first transparent electrode.

[0064] For example, for the ADS (Advanced Smart Display System, advanced ultra-dimensional field switching technology) mode, when the first transparent electrode is in the shape of a slit, the second transparent electrode can be in the shape of a plate; and, the second transparent electrode and the first transparent electrode on different floors.

[0065] ADS technology is to form a multi-dimensional electric field through the electric field generated by the edge of the slit electrode in the same plane and the electric field generated between the slit electrode layer and the plate electrode layer, so that all the oriented liquid crystal molecules between the slit electrodes and directly above the electrodes in th...

Embodiment approach 2

[0073] Preferably, the first transparent electrode is in the shape of a slit, and the second transparent electrode is in the shape of a slit.

[0074] Preferably, the second transparent electrode is located on a different layer from the first transparent electrode, or

[0075] The second transparent electrodes are located on the same layer as the first transparent electrodes, and the second transparent electrodes and the first transparent electrodes are arranged crosswise.

[0076] In a specific implementation, when the second transparent electrodes are located in different layers from the first transparent electrodes, an insulating member may be provided between adjacent second transparent electrodes, or the insulating member may not be provided.

[0077] Preferably, when the second transparent electrode and the first transparent electrode are located in different layers, the insulating component is located between two adjacent second transparent electrodes, and the upper sur...

Embodiment 1

[0173] In Embodiment 1 of the present invention, the first transparent electrode is a pixel electrode, and the second transparent electrode is a common electrode, and the first transparent electrode is in the shape of a slit, and the second transparent electrode is in the shape of a plate.

[0174] Preferably, the manufacturing method of the array substrate in the embodiment of the present invention includes:

[0175] Step A1, forming gates and gate lines on the base substrate;

[0176] Among them, such as Figure 5A As shown, the formed gate 1 and gate line 10 are connected to each other.

[0177] Step A2, forming a gate insulating layer covering the gate and gate lines on the base substrate;

[0178] Step A3, forming an active layer on the gate insulating layer;

[0179] Among them, such as Figure 5A As shown, the formed gate 1 completely covers the active layer 2 .

[0180] Step A4, forming source electrodes, drain electrodes and data lines on the active layer;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com