Counterflow closed cooling tower

A closed cooling tower and counter-flow technology, applied in water shower coolers, direct contact heat exchangers, heat exchange equipment, etc., can solve problems such as easy blockage of air ducts, inability to change water volume, and excessive cooling capacity, and achieve Eliminate white fog phenomenon, reduce the risk of icing, and satisfy the effect of cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

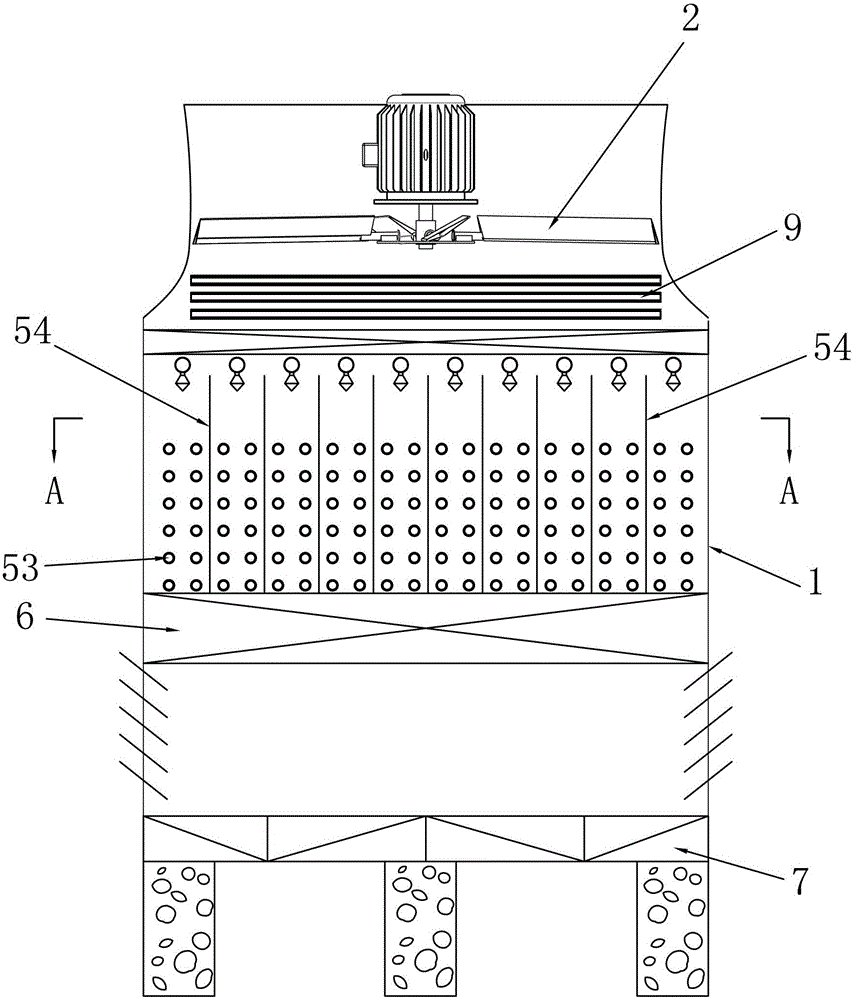

[0027] like figure 1 As shown, like the prior art, the first embodiment of the counterflow closed cooling tower of the present invention includes a tower body 1, and the tower body 1 is respectively provided with a fan 2, a water eliminator 3, a water distribution device, The first heat exchanger 5, filler 6 and water collection tank 7, the side wall of the tower body 1 is provided with an air inlet, the air inlet is located between the filler 6 and the water collection tank 7, and the air inlet is provided with an air inlet louver 8, which is similar to the existing The technical difference is: the tower body 1 is also provided with a second heat exchanger 9, the second heat exchanger 9 is located between the fan 2 and the water eliminator 3, the second heat exchanger 9 is connected to the first heat exchanger 5 In addition, the water distribution device in this embodiment includes ten water distribution pipes 41, each water distribution pipe 41 is distributed from the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com