Elastic dobby fabric with different warp and different weft and its weaving process

A technology of jacquard fabric and different weft is applied in the field of elastic small jacquard fabric with different warp and different weft and its weaving technology, which can solve problems such as defective fabrics, and achieve the effects of easy weaving, less difficulty in weaving and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

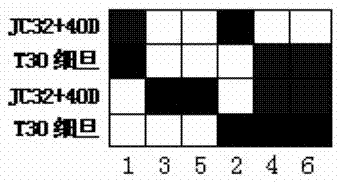

[0021] Example: such as figure 1 As shown, the fabric is designed so that the warp yarn is pure cotton yarn (JC32) and the ratio of pure polyester yarn (T30 fine denier) is 4:2, and the weft yarn is a kind of elastic yarn (JC32+40D) and a kind of pure polyester yarn (T30 fine denier) composition, the ratio is 1:1, and the fabric weave is dobby weave (2 / 2+3 / 1+1 / 3 joint weave) ( figure 1 The number below is the page number of the heald frame).

[0022] The specific implementation process steps of the present invention are: winding process→warping process→sizing process→reeding process→weaving process→finishing process:

[0023] (1) Winding process: use a fully automatic winder to wind the bobbin into a large-capacity, well-formed bobbin with a certain density, and remove impurities to remove defects and impurities on the yarn;

[0024] (2) Warping process: two kinds of warp yarns with a certain number and length are respectively drawn from the winding bobbin to form a yarn she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com