Method for preparing imidafenacin

A technology of midanacin and methylimidazole, which is applied in the field of drug synthesis, can solve the problems of low safety, blindness, unfriendly to the human body and the environment, and achieve the effect of being friendly to the human body and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

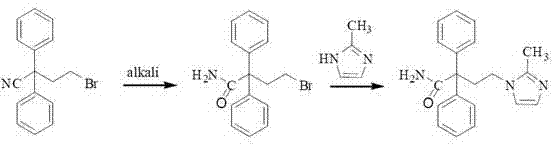

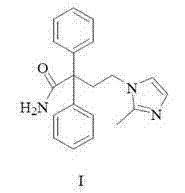

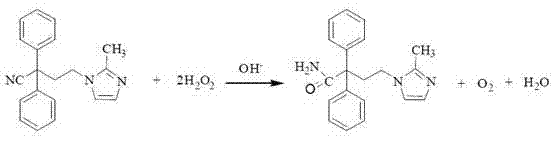

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of 4-bromo-2,2-diphenylbutyronitrile

[0033] Add 400 mL of dry tetrahydrofuran to a 2L reaction flask, add 60% sodium hydride (82.8 g, 2.06 mol) under nitrogen protection, and stir to obtain a gray turbid liquid A. Fully dissolve diphenylacetonitrile (200g, 1.04mol) and 1,2-dibromoethane (204.2g, 1.08mol) with 400mL of dry tetrahydrofuran solution to obtain a colorless clear liquid B; at 5~15℃, the solution B was dropped into the turbid liquid A, and the reaction was kept at 10-15°C for 6 hours. After the reaction was detected by TLC, a small amount of water was dropped into the reaction system until no bubbles were generated. Then, 800 mL of water and 400 mL of ethyl acetate were added and stirred for liquid separation, the organic layer was washed with water and saturated sodium chloride solution, the organic layer was dried with anhydrous sodium sulfate, filtered with suction, and concentrated under reduced pressure to obtain 310 g of yellow liqu...

Embodiment 2

[0036] Example 2: Preparation of 4-bromo-2,2-diphenylbutanamide

[0037] Add 4-bromo-2,2-diphenylbutyronitrile (150g, 0.5mol), 750mL 6mol / L KOH solution, 750mL dimethyl sulfoxide to a 3L reaction flask, and heat to 100~120℃ and stir to react. 1h, after TLC detects that the reaction is completed, the temperature is lowered to 40°C, 2000mL water and 2000mL dichloromethane are added, and the mixture is separated. The organic layer is washed with water, saturated sodium bicarbonate and sodium chloride solution, separated and dried with anhydrous sodium sulfate. The organic layer was filtered with suction and concentrated under reduced pressure to obtain 161.92 g of brown oily liquid with a yield of 96%.

[0038]

Embodiment 3

[0039] Example 3: Preparation of 4-bromo-2,2-diphenylbutanamide

[0040] Add 4-bromo-2,2-diphenylbutyronitrile (150g, 0.5mol), 666mL 6mol / L NaOH solution, and 750mL dimethyl sulfoxide into a 3L reaction flask. Heat to 100~120℃ and stir to react. 1h, after TLC detects that the reaction is completed, the temperature is lowered to 40°C, 2000mL water and 2000mL dichloromethane are added, and the mixture is separated. The organic layer is washed with water, saturated sodium bicarbonate and sodium chloride solution, separated and dried with anhydrous sodium sulfate. The organic layer was filtered with suction and concentrated under reduced pressure to obtain 146.73 g of a brown oily liquid with a yield of 87%.

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com