A preparation method of a phase change energy storage type thermal insulation composite board

A technology for thermal insulation composite panels and phase change energy storage, which is applied in chemical instruments and methods, materials for heat exchange, layered products of hydraulic substances, etc. It has obvious problems such as low heat storage and release capacity, and achieves good chemical stability, improved mechanical properties, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

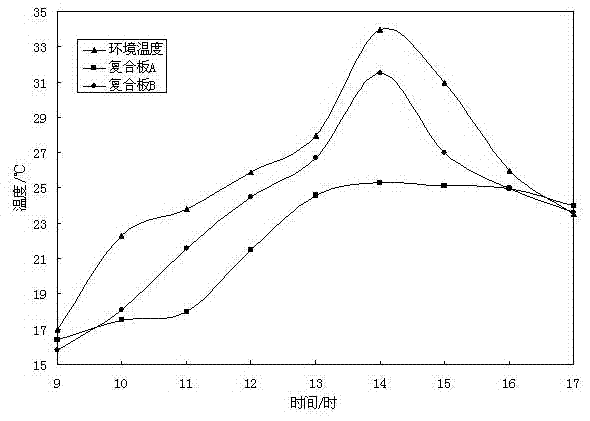

Image

Examples

Embodiment 1

[0025] Paraffin wax with a melting point of 25° C. and a latent heat of phase change of 147 kJ / kg was selected as the organic phase change material. First dissolve 58 parts of paraffin in 280 parts of ethanol solution, heat the organic solution to 40°C, stir at constant temperature for 30 minutes, then slowly add 13 parts of nanometer γ-alumina and 10 parts of coupling agent γ-aminopropyltriethoxy Silane, stirred at high speed for 3 hours, filtered, washed and dried to prepare phase change energy storage aggregates. Then 100 parts of cement, 80 parts of phase change energy storage aggregate, 18 parts of water and 2 parts of reinforcing fiber are blended, stirred evenly, put into a mold and pressed to obtain a phase change energy storage surface layer. The latent heat value of the phase change energy storage surface layer measured by DSC is 52kJ / kg.

[0026] The polyurethane foam board added with flame retardant is used as the insulation board, and the phase change energy stor...

Embodiment 2

[0033] Paraffin wax with a melting point of 30° C. and a latent heat of phase change of 155 kJ / kg was selected as the organic phase change material. Dissolve 20 parts of paraffin in 100 parts of ethanol solution, heat to 50°C, stir at constant temperature for 30 minutes, then slowly add 5 parts of γ-alumina and 6 parts of coupling agent γ-mercaptopropyltrimethoxysilane, and stir at high speed for 3 hours After filtering, washing and drying, the phase change energy storage aggregate can be prepared. Then blend 100 parts of plaster of paris, 30 parts of phase change energy storage aggregate, 35 parts of water, 1 part of reinforcing fiber and 0.5 part of retarder, mix well, put it into a mold and press it to obtain phase change energy storage Surface layer. The latent heat value of the phase change energy storage surface layer measured by DSC is 29kJ / kg.

[0034] The phenolic foam board added with flame retardant is used as the insulation board, and the phase-change energy stor...

Embodiment 3

[0036] Paraffin wax with a melting point of 49°C and a latent heat of phase change of 165kJ / kg was selected as the organic phase change material. First dissolve 40 parts of paraffin in 100 parts of ethanol, heat to 50°C, stir at constant temperature for 30 minutes, then slowly add 7 parts of nanometer γ-alumina and 6 parts of coupling agent γ-aminopropyltriethoxysilane, and stir at high speed After 3 hours, the phase change energy storage aggregate can be prepared after filtering, washing and drying. Then blend 100 parts of plaster of paris, 50 parts of phase change energy storage aggregate, 40 parts of water, 1 part of reinforcing fiber and 0.5 part of retarder, mix well, put it into a mold and press it to obtain phase change energy storage Surface layer. The latent heat value of the phase change energy storage surface layer measured by DSC is 44kJ / kg.

[0037] The polyurethane foam board added with flame retardant is used as the insulation board, and the phase change energ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com