An internal mixer rotor for mixing short-fiber rubber composite materials

A technology of short-fiber rubber and composite materials, which is applied in the field of rubber product processing, and can solve the problems of not being able to meet the special mixing requirements of short-fiber rubber composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

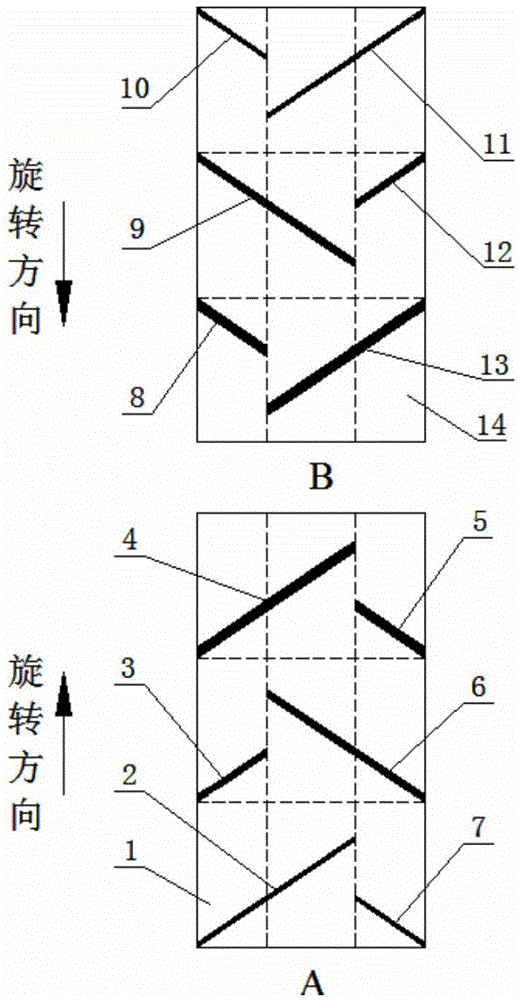

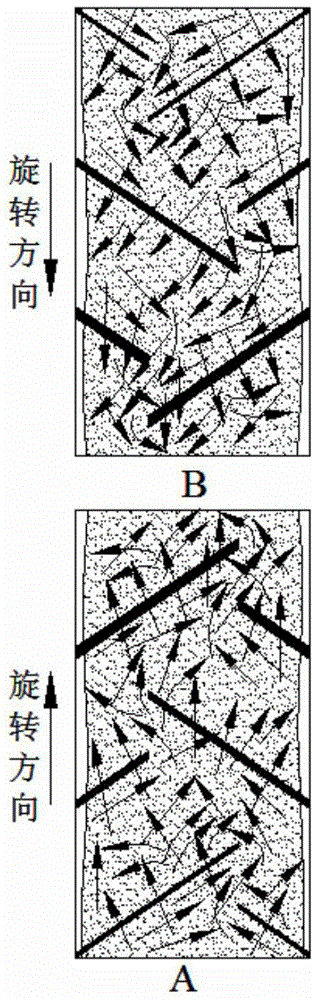

[0012] The whole of this embodiment includes a front rotor A and a rear rotor B, with a speed ratio of 1:1, rotating in opposite directions, which is performed on an X(S)M-1.7 internal mixer experimental platform. Front rotor A, the rotor prisms 2, 3, 4, 5, 6, 7 are welded to the rotor body 1. According to the gap between the top of the ridge and the inner wall of the mixing chamber, it is divided into small gap rotor long rib 2, small gap rotor short Edge 7, medium gap rotor long edge 6, medium gap rotor short edge 3, large gap rotor long edge 4, large gap rotor short edge 5; small gap rotor long edge 2, medium gap rotor short edge 3, large gap rotor long edge 4 Distributed on the left side of the rotor body 1, left-handed, the starting point of the spiral is uniformly distributed at 120° in the circumferential direction, and the spiral angle is 34 to 35°. The short edge of the rotor with small gaps is 7, the long edge of the rotor with medium gaps is 6, and the gap is large. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com