Multilayer injection molding ceramic cutting tool

A technology for ceramic knives and ceramics, applied in hand-held tools, manufacturing tools, metal processing, etc., can solve the problems of plastic shrinkage, affecting the appearance of knives, loose ceramic blades, etc., to achieve easy cleaning, reduce surface defects, and reduce injection molding costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

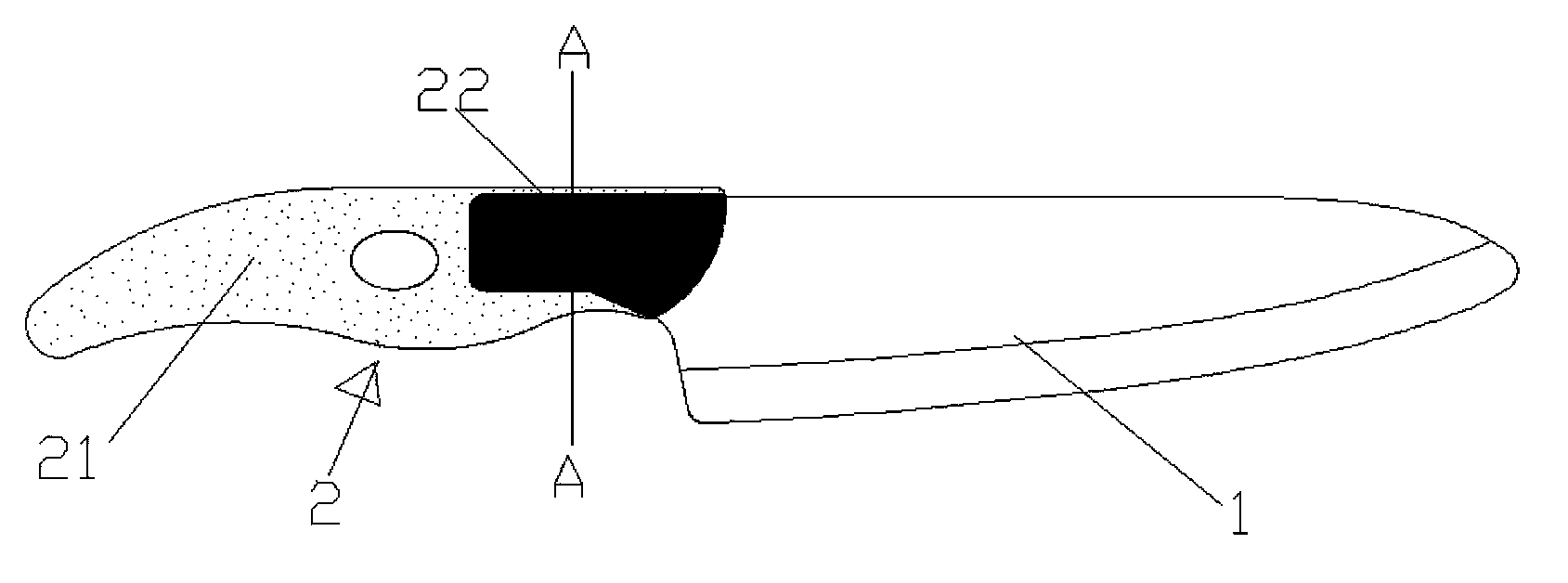

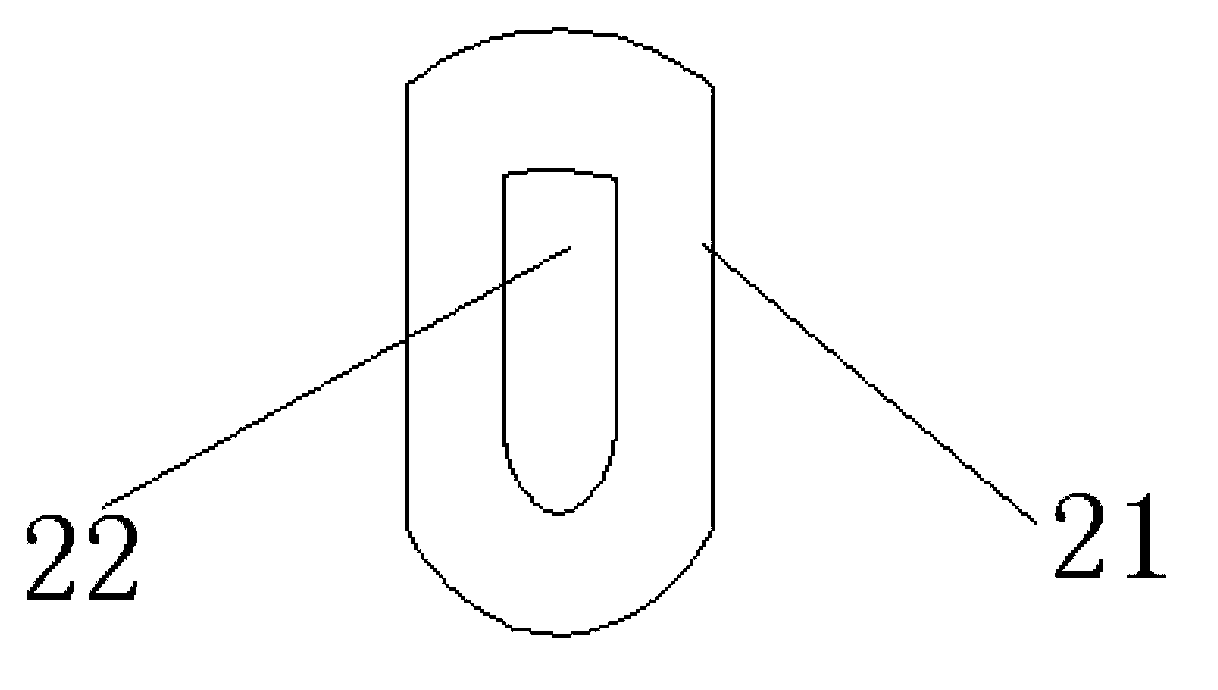

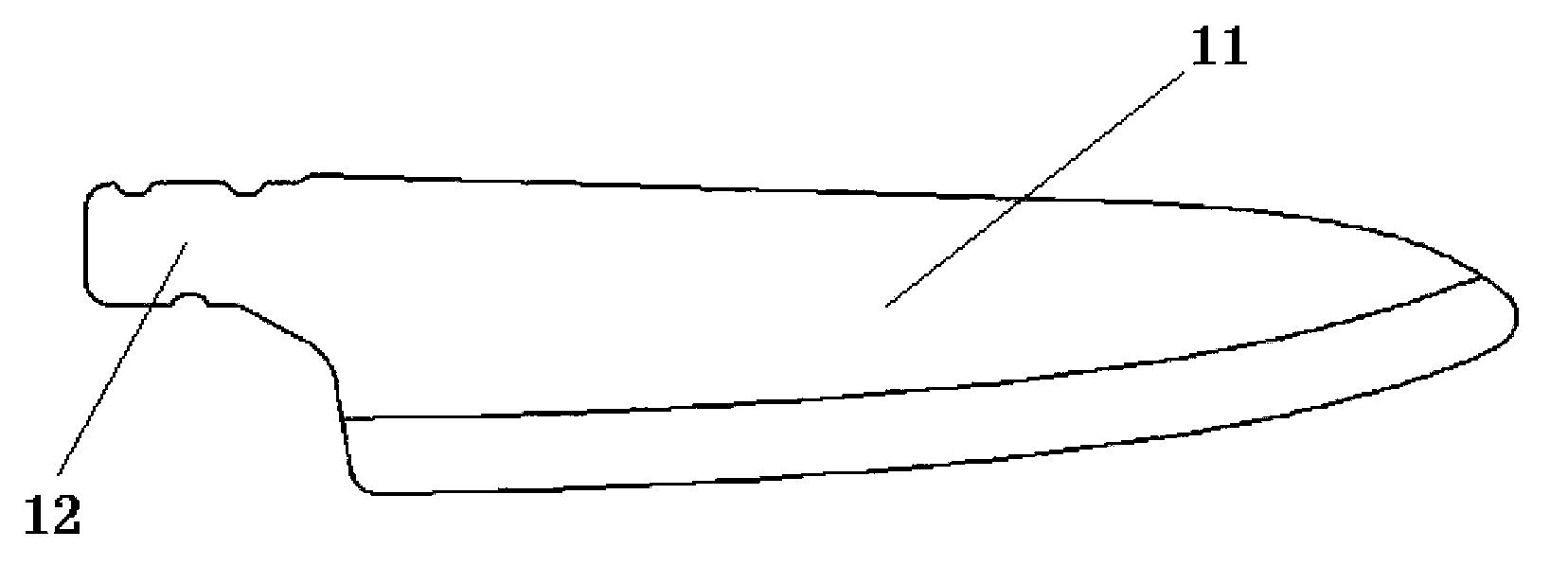

[0020] Such as figure 1 , figure 2 with image 3 As shown, a multilayer injection molded ceramic knife includes a ceramic blade 1 and a handle 2, the ceramic blade includes a handle 12 and a blade 11, and the handle is integrally formed with the handle at least twice to form a multilayer structure , In this way, through multiple injections, defects on the surface of the tool handle caused by injection shrinkage can be reduced, which affects the appearance and feel of the tool.

[0021] Preferably, the handle is integrally formed with the handle by two injection moldings to form a double-layer structure. In this way, two injection moldings can reduce the surface defects of the tool handle and reduce injection molding costs.

[0022] Preferably, the double-layer structure includes an inner layer 22 and an outer layer 21, the inner layer covers the handle, and the outer layer partially covers the inner layer. In this way, as required, The handle is first injection molded into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com