COB (chip on board) optical component automatic testing sorting machine

An automatic testing and sorting machine technology, applied in sorting and other directions, can solve problems such as complex feeding methods, poor compatibility, and high cost, and achieve the effects of avoiding the influence of human factors, reducing labor intensity, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

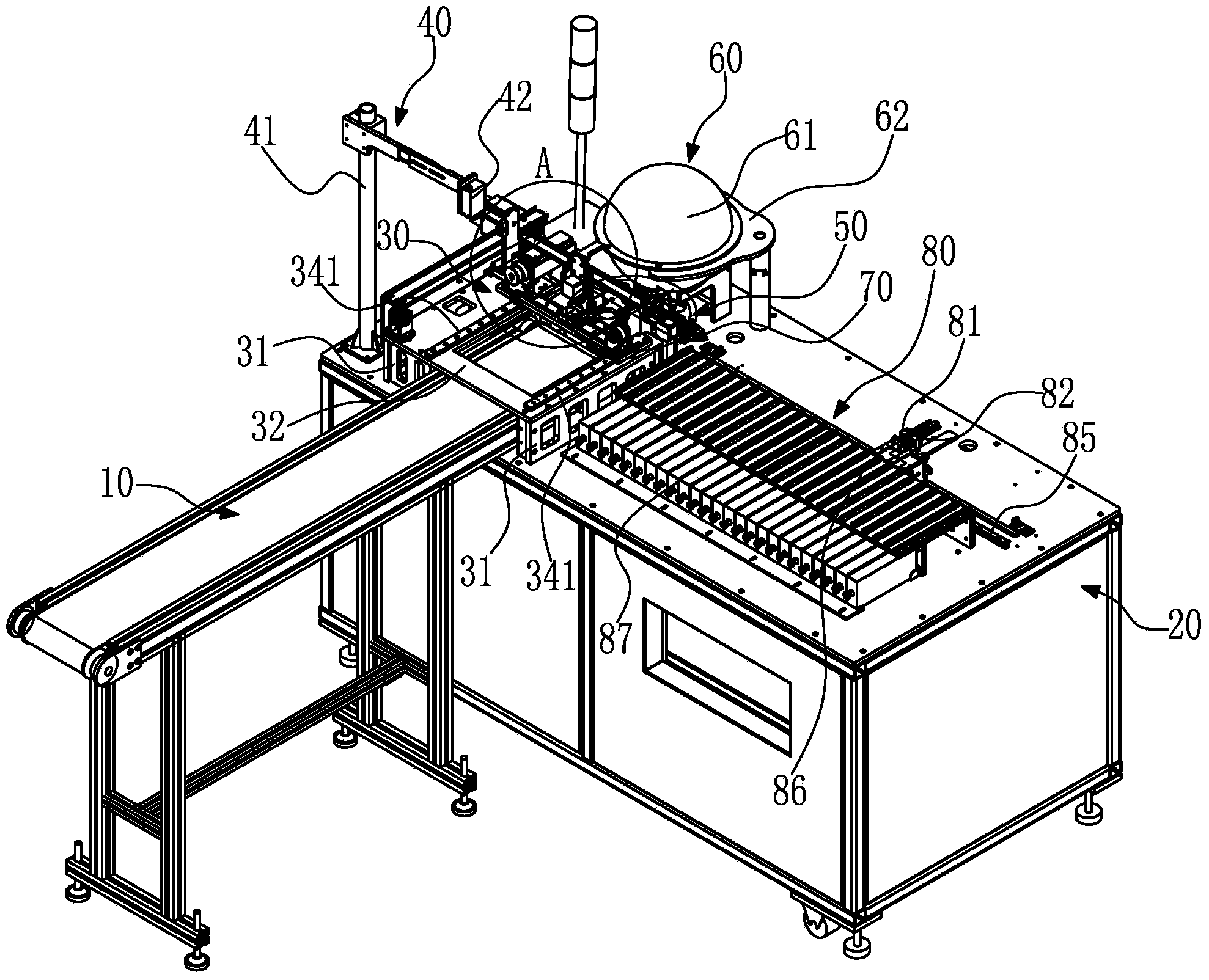

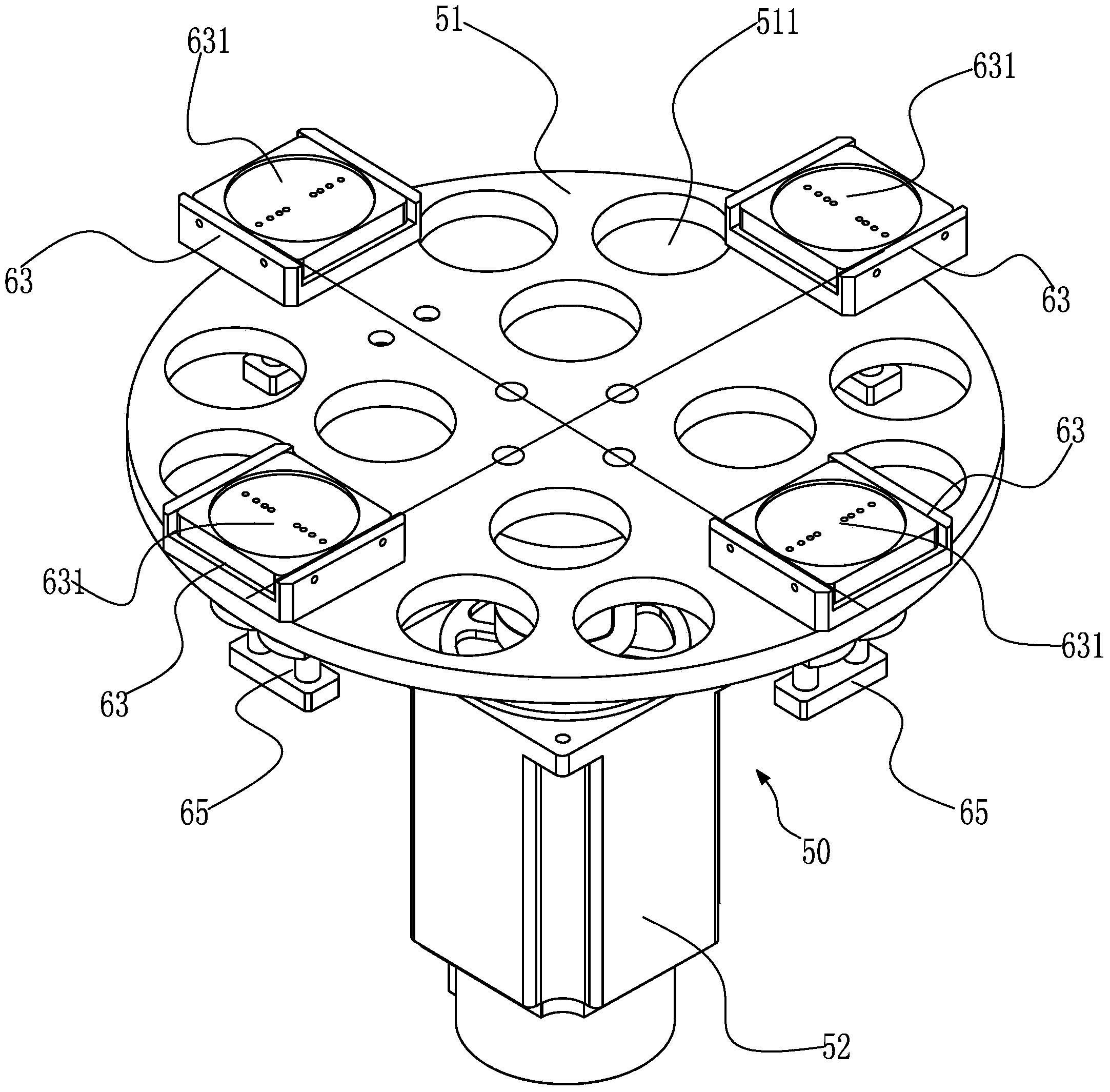

[0067] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of a preferred embodiment of the present invention, a COB optical component automatic test and sorting machine, including a conveyor belt 10, a machine table 20, a feeding mechanism 30, an automatic identification mechanism 40, and a turntable mechanism 50. Testing mechanism 60, unloading mechanism 70 and sorting and receiving mechanism 80, one end of the conveyor belt 10 is installed on the outside of the machine platform 10, and the other end is installed on the machine platform 10, the feeding mechanism 30, the automatic identification mechanism 40 , the turntable mechanism 50, the testing mechanism 60, the unloading mechanism 70 and the sorting and receiving mechanism 80 are installed on the machine platform 20;

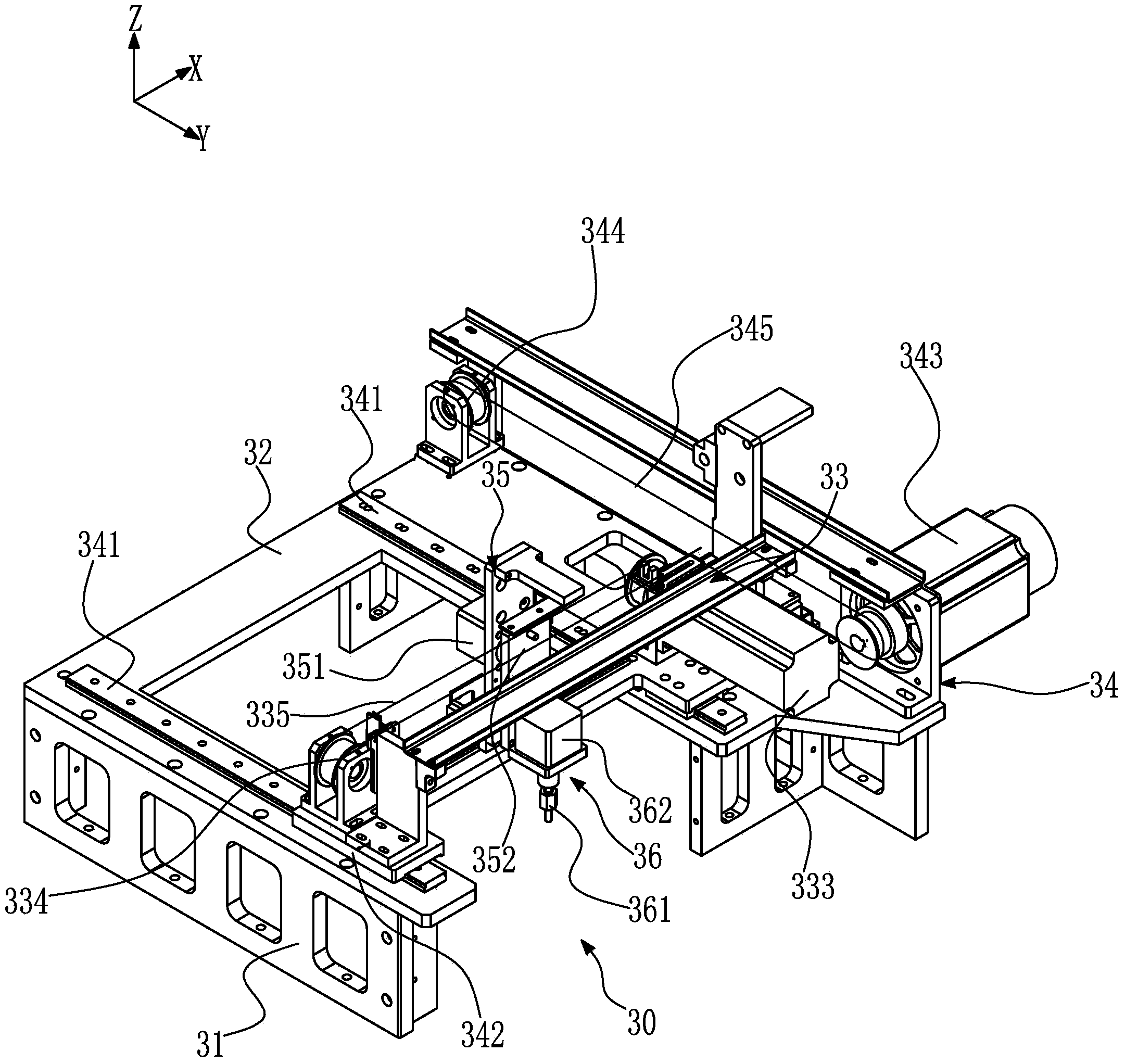

[0068] The feeding mechanism 30 is installed above the conveyor belt 10 and the turntable mechanism 50 at the machine platform 20, the automatic identification mechanism 40 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com