Full-automatic feather punching and shearing forming machine

A molding machine, fully automatic technology, applied in metal processing, etc., can solve problems such as inaccurate fixture positioning, inconsistent chain tightness, unsatisfactory, etc., to achieve the effect of improving feeding accuracy, improving work quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

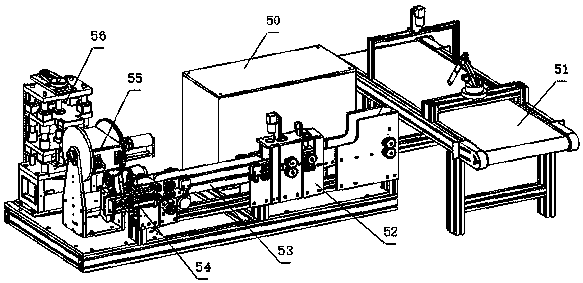

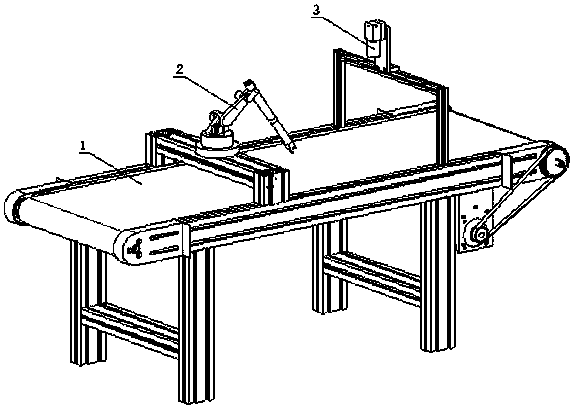

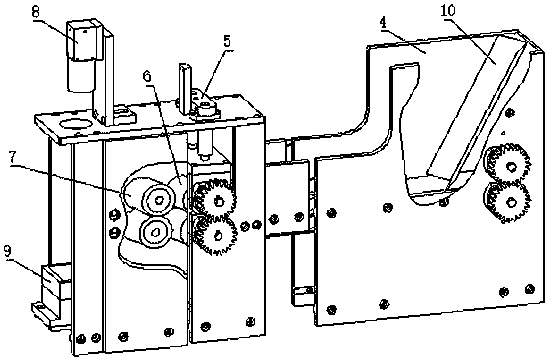

[0032] Attached below Figure 1-Figure 8 The present invention is described in further detail:

[0033] The full-automatic feather punching and shearing forming machine of the present invention comprises a frame, a controller 50 and an automatic feeding mechanism 51 fixed on the frame connected with the controller 50 signal, a finishing mechanism 52, a transmission mechanism 53, a positioning Hair feeding mechanism 54, rotating mechanism 55 and hair flushing mechanism 56. Wherein, the controller 50 is responsible for coordinated control, and the automatic feeding mechanism 51 is responsible for orderly feeding the finishing mechanism 52. The finishing mechanism 52 arranges the feathers to be processed in the direction of the flakes and then transmits them to the positioning hair feeding mechanism 54 through the transmission mechanism 53. The positioning and feeding mechanism 54 straightens the feathers to be processed, and the rotating mechanism 55 picks up the straightened f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com