Preparation method for phosphor-doped graphite-phase carbon nitride visible-light catalyst

A graphitic carbon nitride, visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the limitation of visible light absorption and utilization, and degrade pollutants Due to the limited improvement of photocatalytic activity, the effects of being suitable for large-scale production, simple preparation method and wide source of raw materials are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

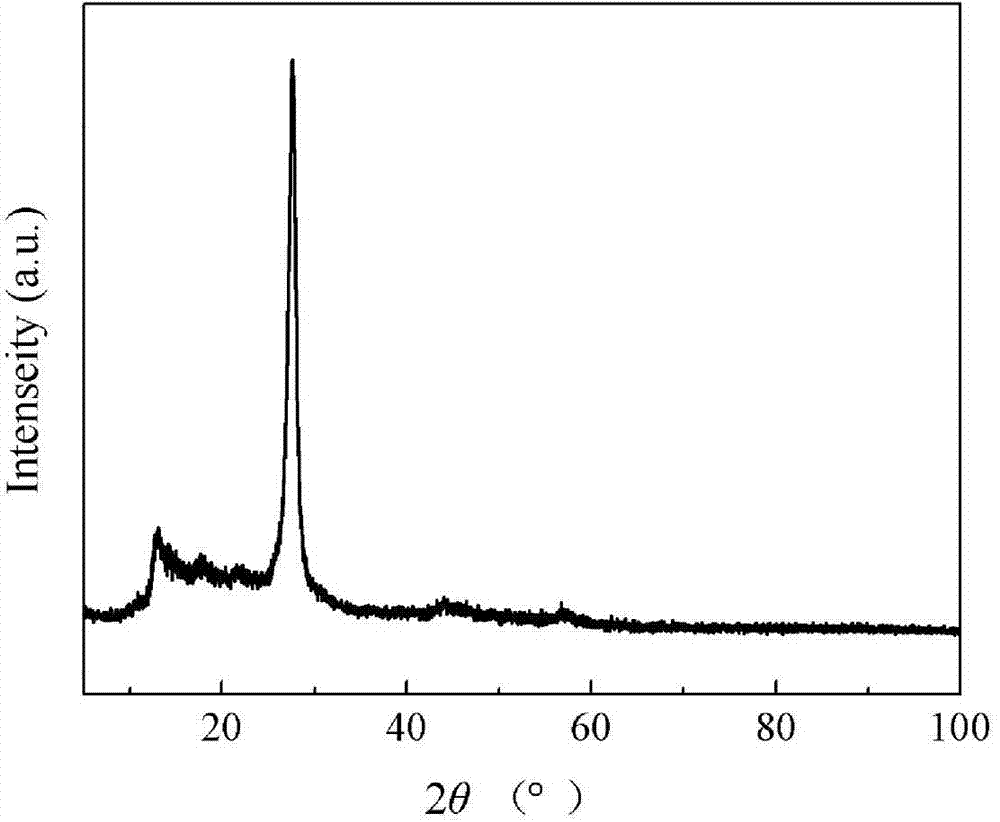

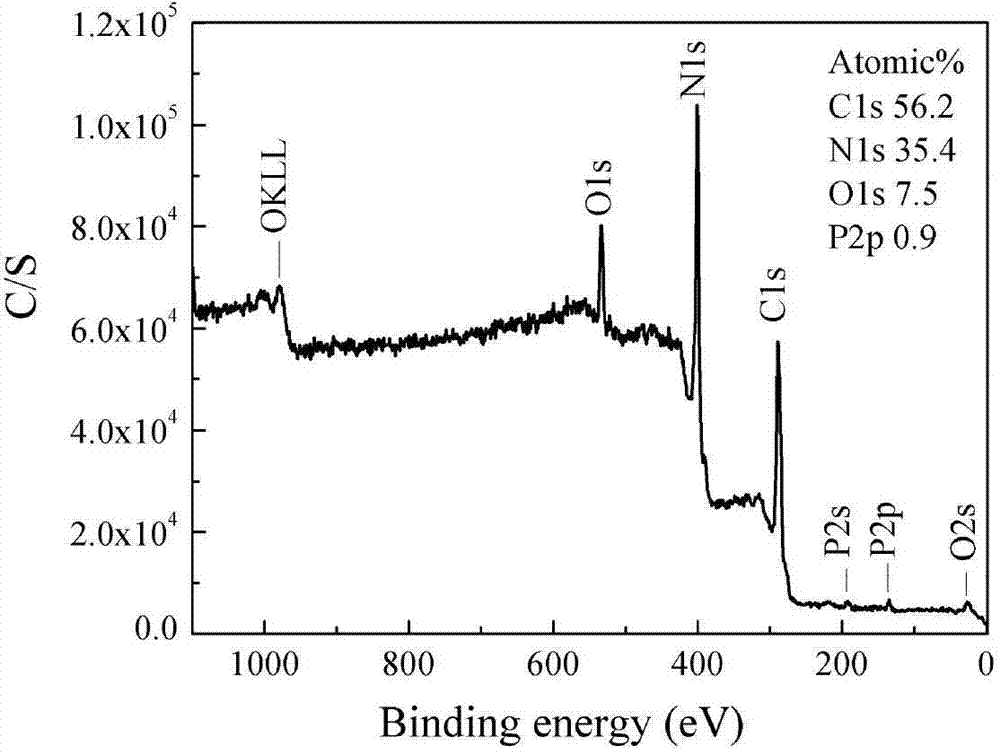

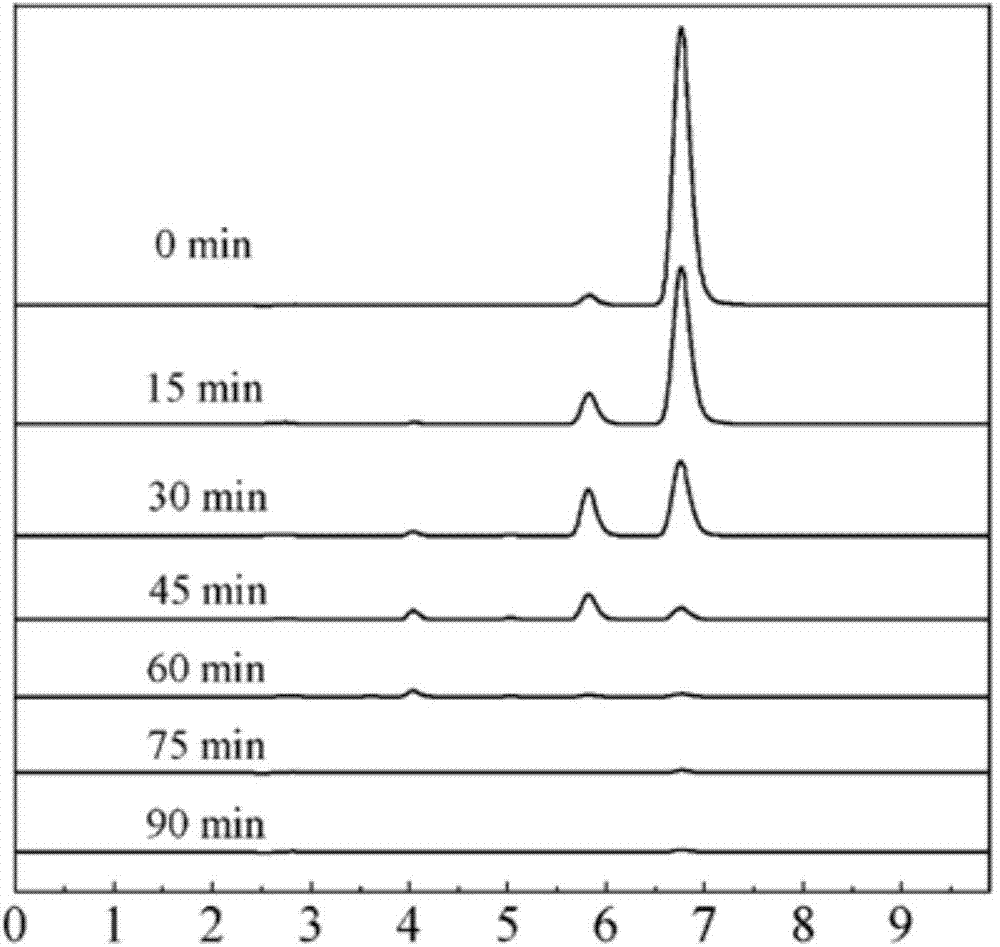

[0022] Pipette 1 mL of dilute phosphoric acid solution with a concentration of 0.793 mol / L and add it to a beaker containing 5 mL of deionized water, stir for 10 min, then slowly add 5.00 g of melamine solid powder into the dilute phosphoric acid solution under stirring, and continue stirring for 50 min to make Phosphoric acid is uniformly adsorbed and dispersed on the surface of melamine particles. The resulting suspension was heated to 80°C with stirring to remove the solvent water, and then dried in an oven at 80°C for 2 h. Put the dried mixture in a crucible, cover the crucible and put it into a muffle furnace. First, heat up to 300°C within 15 minutes, keep the temperature constant for 1 hour, then raise the temperature to 350°C, keep the temperature constant for 1 hour, then raise the temperature to 400°C, keep the temperature constant 1h, then raise the temperature to 480°C, keep the temperature for 1h, then raise the temperature to 500°C, keep the temperature for 1h, a...

Embodiment 2

[0027] Pipette 0.5 mL of dilute phosphoric acid solution with a concentration of 0.793 mol / L and add it to a beaker containing 5 mL of deionized water, stir for 5 min, then slowly add 5.00 g of melamine solid powder into the dilute phosphoric acid solution under stirring, and continue stirring for 30 min. Make phosphoric acid evenly adsorbed and dispersed on the surface of melamine particles. The resulting suspension was heated to 80°C with stirring to remove the solvent water, and then dried in an oven at 80°C for 2 h. Put the dried mixture in a crucible, cover the crucible and put it into a muffle furnace. First, heat up to 300°C within 15 minutes, keep the temperature constant for 1 hour, then raise the temperature to 350°C, keep the temperature constant for 1 hour, then raise the temperature to 400°C, keep the temperature constant 1h, then raise the temperature to 480°C, keep the temperature for 1h, then raise the temperature to 500°C, keep the temperature for 1h, and fina...

Embodiment 3

[0029] Pipette 2.5 mL of dilute phosphoric acid solution with a concentration of 0.793 mol / L into a beaker containing 5 mL of deionized water, stir for 10 min, then slowly add 5.00 g of melamine solid powder into the dilute phosphoric acid solution while stirring, and continue stirring for 60 min. Make phosphoric acid evenly adsorbed and dispersed on the surface of melamine particles. The resulting suspension was heated to 80°C with stirring to remove the solvent water, and then dried in an oven at 80°C for 2 h. Put the dried mixture in a crucible, cover the crucible and put it into a muffle furnace. First, heat up to 300°C within 15 minutes, keep the temperature constant for 1 hour, then raise the temperature to 350°C, keep the temperature constant for 1 hour, then raise the temperature to 400°C, keep the temperature constant 1h, then raise the temperature to 480°C, keep the temperature for 1h, then raise the temperature to 500°C, keep the temperature for 1h, and finally rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com