Suspensions containing atrazine and chloroacetamide pesticides

A chloroacetamide, suspoemulsion technology, applied in the directions of herbicides and algicides, biocides, biocides, etc., can solve the dynamic and thermodynamic instability, the pH value or viscosity can not be kept constant, the ecology and toxicity are not stable. completely satisfactory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of atrazine into a suspension agent is: adding the weighed original drug atrazine, dispersant, antifreeze, thickener, preservative, and water into a shearing kettle to disperse evenly, and then enter a sand mill. Grind to the required particle size (the average particle size is less than 3 microns), and finally add the defoamer and stir evenly.

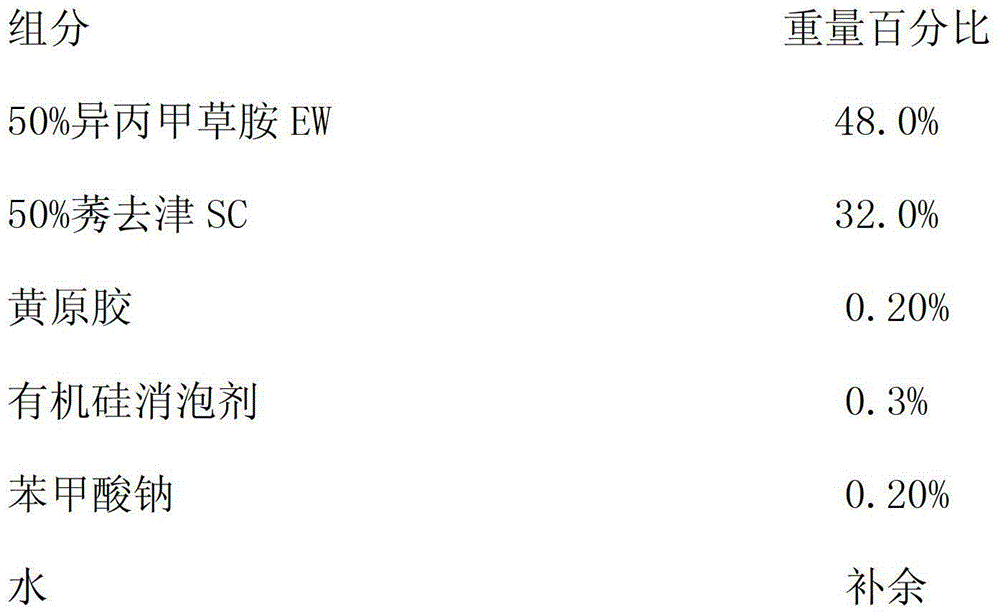

[0024] Preparation of suspoemulsion: the present invention adds oil phase, atrazine suspending agent, stabilizer, preservative, defoamer and water to the shearing kettle for uniform dispersion, and the shearing time is 5-10 minutes (rotation speed is 2950rmp), namely A suspoemulsion is obtained, and the average particle size is controlled to be less than 3 microns.

Embodiment 1

[0026] Embodiment 1: 40% atrazine.Metolachlor suspoemulsion

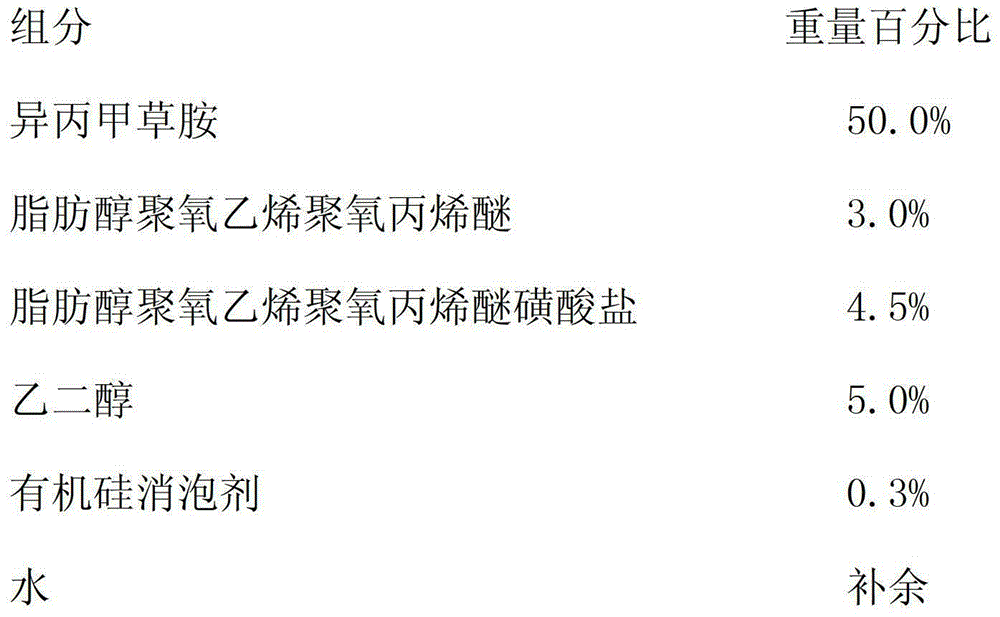

[0027] 1.1 Preparation of 50% metolachlor EW

[0028]

[0029] Process: According to the formula given above, add metolachlor first, then add emulsifier fatty alcohol polyoxyethylene polyoxypropylene ether and fatty alcohol polyoxyethylene polyoxypropylene ether sulfonate, antifreeze ethylene glycol , constitute the oil phase, and then slowly add water under stirring, the system gradually thickens, when it reaches the thickest (that is, the inversion point), slow down the stirring speed, and finally make up the remaining water, add silicone to defoaming agent, sheared by high shear machine for about 0.5 hours (rotation speed is 2950rmp), that is, water emulsion is obtained, and the average particle size is controlled to be less than 3 microns.

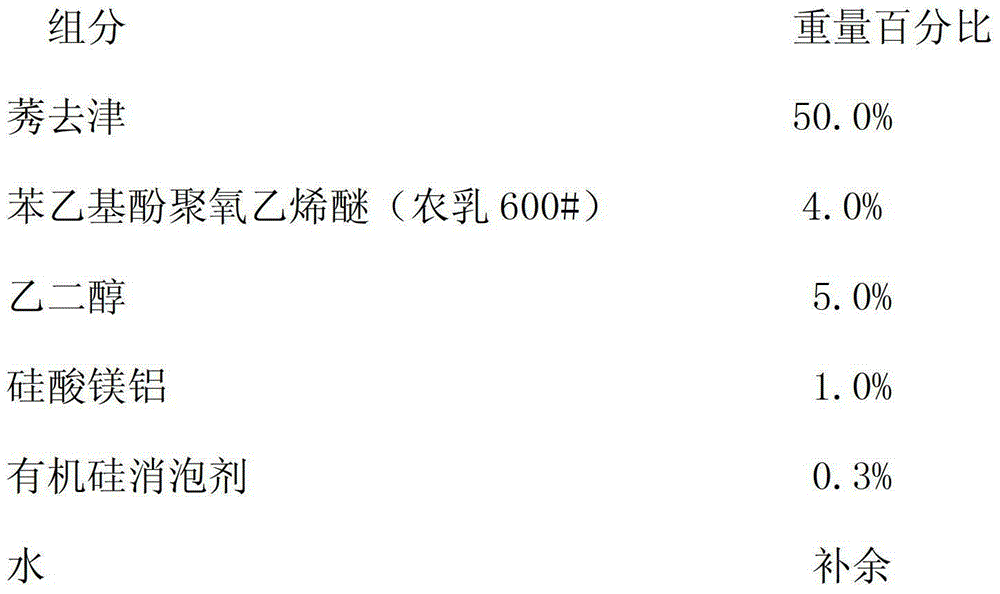

[0030] 1.2 Preparation of 50% Atrazine SC

[0031]

[0032] Process: According to the formula given above, add the weighed original drug atrazine, dispersant agricul...

Embodiment 2

[0039] Embodiment 2: 50% atrazine.Metolachlor suspoemulsion

[0040] 2.1 Preparation of 55% metolachlor EW

[0041]

[0042] Process: According to the formula given above, add metolachlor first, then add emulsifier fatty alcohol polyoxyethylene polyoxypropylene ether and fatty alcohol polyoxyethylene polyoxypropylene ether sulfosuccinate, antifreeze propylene glycol , constitute the oil phase, and then slowly add water under stirring, the system gradually thickens, when it reaches the thickest (that is, the inversion point), slow down the stirring speed, and finally make up the remaining water, add silicone to defoaming agent, sheared by high shear machine for about 0.5 hours (rotation speed is 2950rmp), that is, water emulsion is obtained, and the average particle size is controlled to be less than 3 microns.

[0043] 2.2 Preparation of 50% Atrazine SC

[0044]

[0045]

[0046] Process: According to the formula given above, add the weighed technical atrazine, disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com