Electronic device interconnection body

A technology for electronic devices and interconnects, applied in the field of integrated circuit semiconductor packaging, can solve the problems of time-consuming, time-consuming and difficult manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

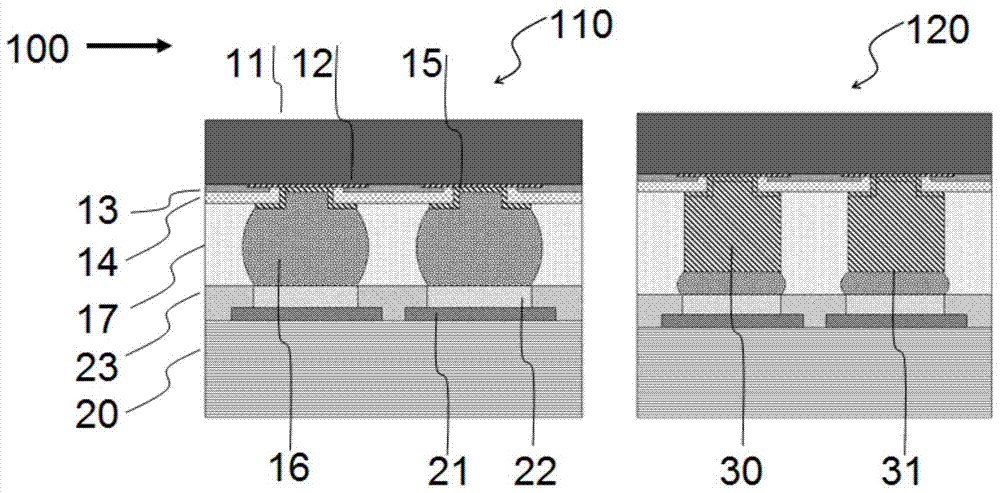

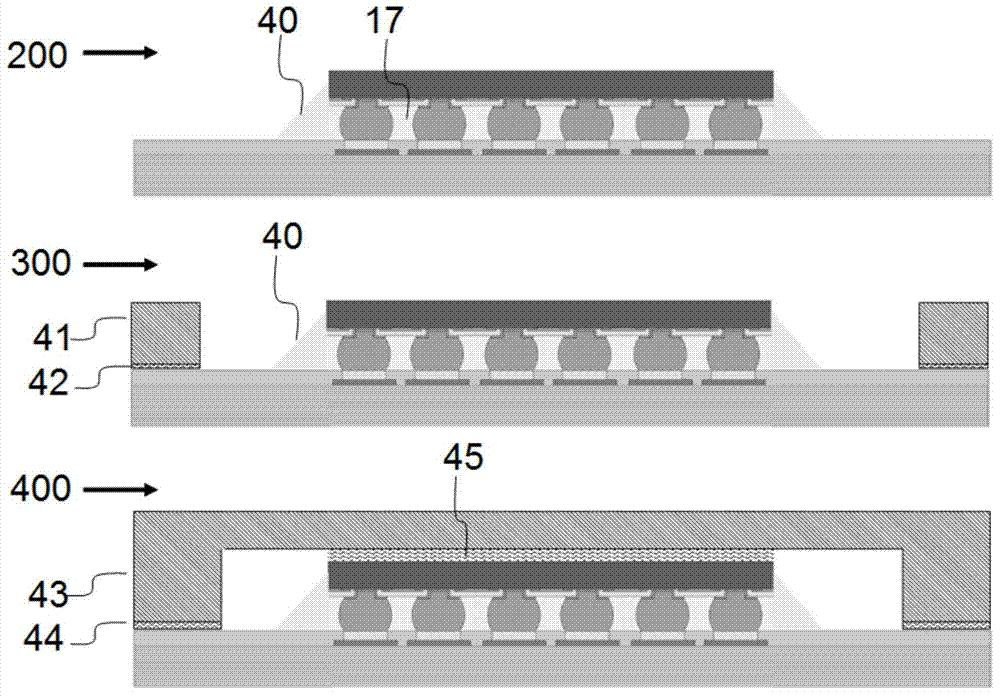

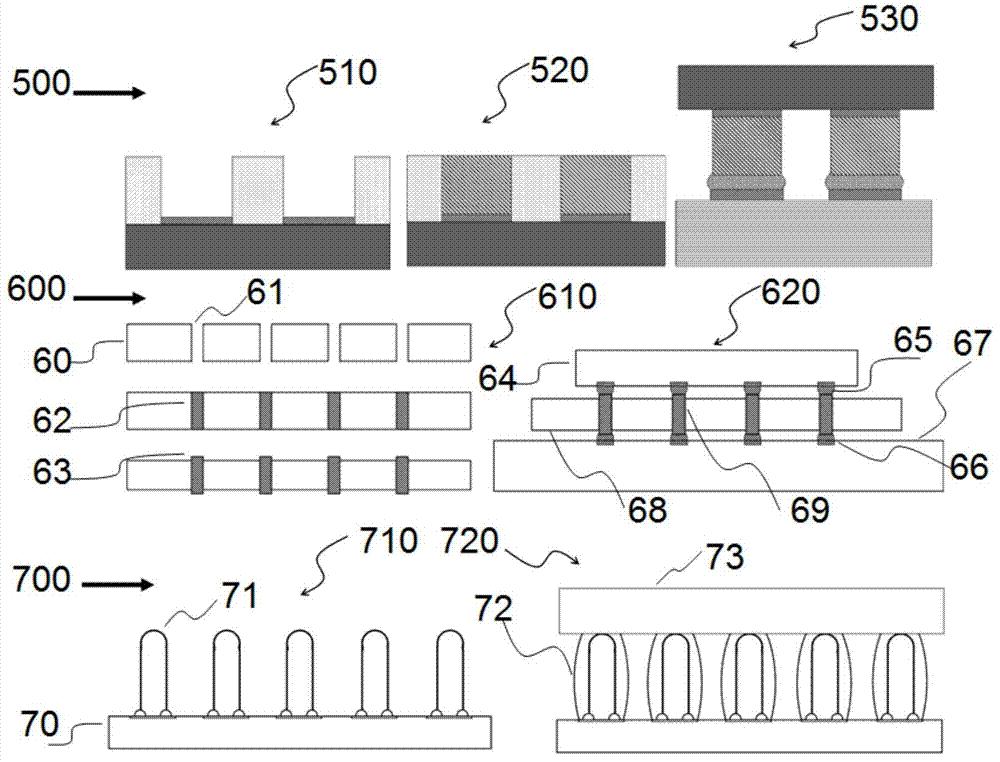

[0044] In order to clearly describe specific embodiments of the present invention by referring to the accompanying drawings, some terms used are first explained as follows: 1) Unidirectional conductive plate, which represents a sheet that conducts electricity in the thickness direction of the plate and insulates in the in-plane direction of the plate Shaped material, where conduction in the thickness direction of the plate does not mean that any position of the plate is conductive in the thickness direction of the plate, but means that on a relatively large scale, any position of the plate conducts electricity in the thickness direction of the plate, or means Conduct electricity in the thickness direction of the board at the positions arranged at a set interval; while for the substrate bonding material is a conductive material, such as a low-melting point metal material, unidirectional conduction means that the conductors are insulated from each other in the in-plane direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com