Chucking device and chucking method

A substrate card, vacuum suction technology, applied in workpiece clamping devices, electrical components, sleeve/socket connections, etc., can solve problems such as difficult control, small width, wafer distortion, etc., and achieve the effect of eliminating warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

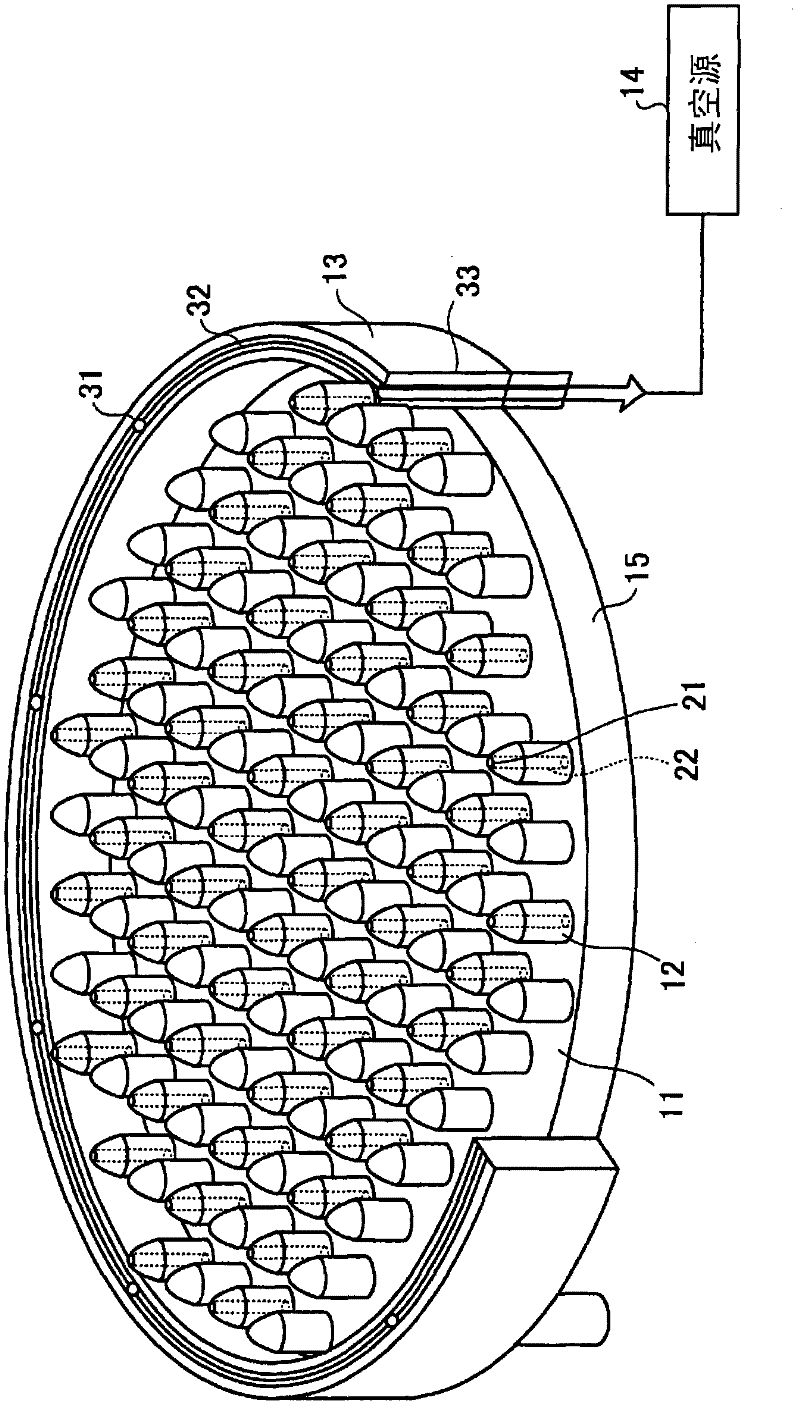

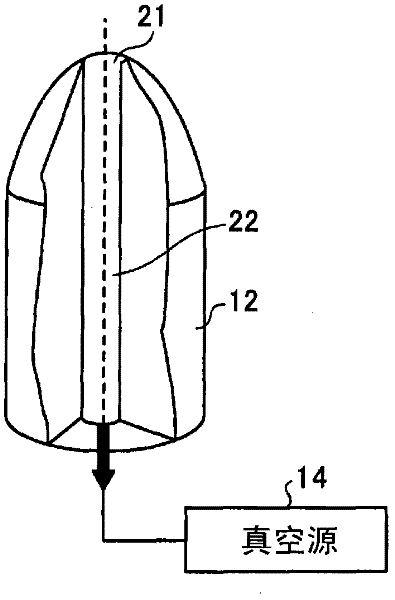

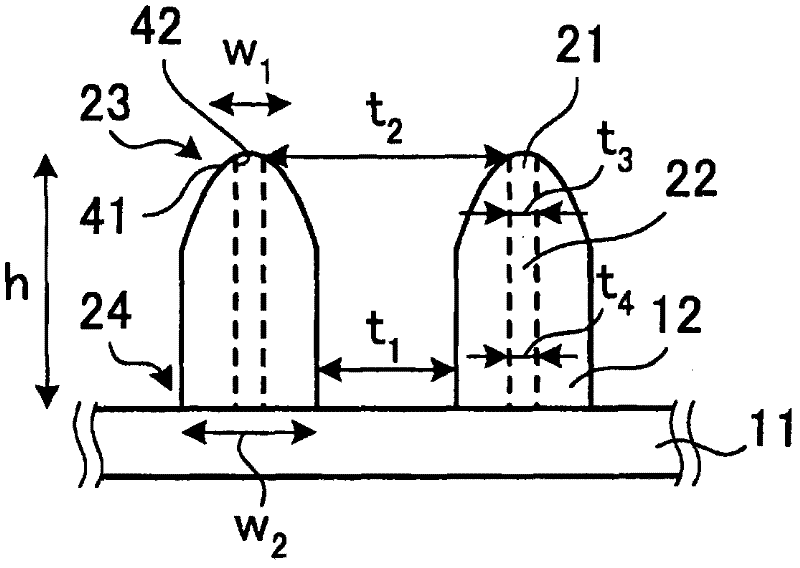

[0089] figure 1 is a view schematically showing the chucking device according to the first embodiment. also, figure 2 and 3 is schematically showing the structure figure 1 Views of the components of the snap-in device shown. figure 1 The shown suction device includes a base 11, a cylindrical peripheral portion 13, a plurality of suction holes 21 and 31, and a vacuum source 14, the base 11 is provided with a plurality of protrusions 12 supporting the central portion of the semiconductor substrate, and the cylindrical peripheral portion The portion 13 supports the outer peripheral portion of the semiconductor substrate, the plurality of suction holes 21 and 31 chuck the semiconductor substrate, and the vacuum source 14 vacuums the plurality of suction holes at different timings.

[0090] The base 11 has, for example, a circular planar shape. The diameter of the base 11 is slightly smaller than that of the semiconductor substrate. In addition, the base 11 may be compose...

no. 2 example

[0142] Figure 11 is a view showing a chucking method using a chucking device according to the second embodiment. In the first embodiment, it is possible to chuck a semiconductor substrate (hereinafter referred to as a ribbed wafer) 51 having a stepped form due to a peripheral portion 52 remaining thickly around the periphery.

[0143] In the second embodiment, as Figure 11 As shown in FIG. and the second suction hole 31 provided in the peripheral portion 13 . In addition, the height h of the protruding portion 12 can be made higher than that of the outer peripheral portion 13, and the depressed portion of the ribbed wafer 51 which is thinner due to the outer peripheral portion 52 is only snapped to the first suction provided in the protruding portion 12. Holes 21 (not shown). In this case, the outer peripheral portion 52 of the ribbed wafer 51 can be snapped to the second suction holes 31 provided in the peripheral portion 13 . The structure of the sucking device and th...

no. 3 example

[0146] Figure 12 and 13 is a view showing a chucking method using the chucking device according to the third embodiment. In the first embodiment, the peripheral portion 53 may be provided so as to be able to be raised and lowered in the vertical direction with respect to the surface of the semiconductor substrate supported on the peripheral portion 53 .

[0147] A description is given of the chucking method of the third embodiment, taking, for example, the case of chucking the rear surface side of a semiconductor substrate that is concave and warped on the front surface side as an example. First, using a transfer arm (not shown) or the like, the semiconductor substrate 1 is placed with the rear surface downward on the peripheral portion 53 installed so as to be able to be raised and lowered above the base 11, as shown in FIG. Figure 12 shown. Next, a second step of snapping the outer peripheral portion of the rear surface of the semiconductor substrate 1 to the second suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com