A device and method for detecting the lifting speed of a combine harvester header

A combine harvester, lifting speed technology, applied to the use of devices for measuring the time required to move a certain distance, radio wave measurement systems, electromagnetic wave re-radiation, etc., can solve the problems of low accuracy, inability to automatically enter data, and inconvenient operation. problems, to achieve good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

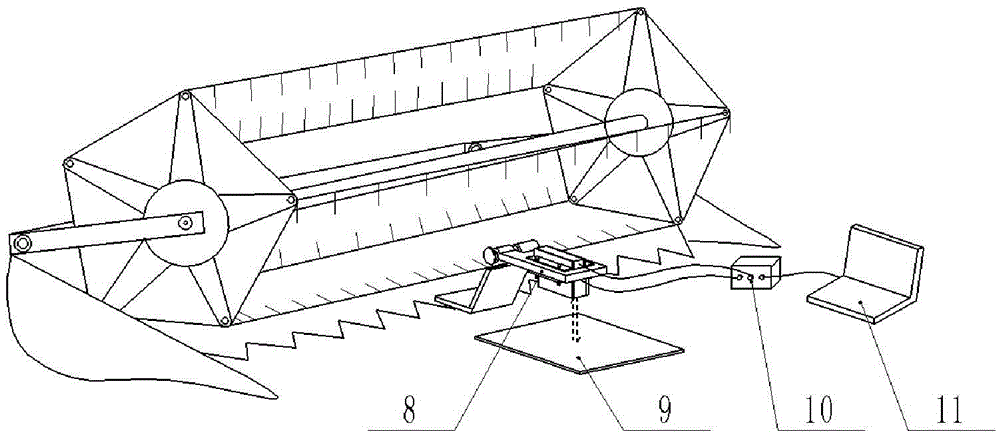

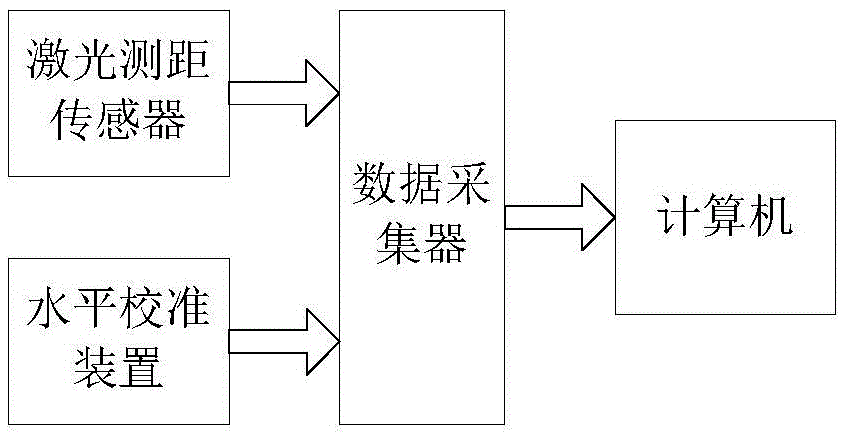

[0033] The assembly relationship between the combine harvester header lifting speed detection device of the present invention and the harvester under test is as follows: figure 1 As shown, the combine harvester header lifting speed detection device includes a mechanical part, a data collector 10 and a computer 11 . The mechanical part is installed on the tip of the cutter of the inspected harvester, connected with the computer 11 through the data collector 10, including adjustable angle bracket, powerful magnet 2, angle adjustment bolt 4, laser distance measuring sensor 5, L-shaped sensor support 6, Leveling device 7.

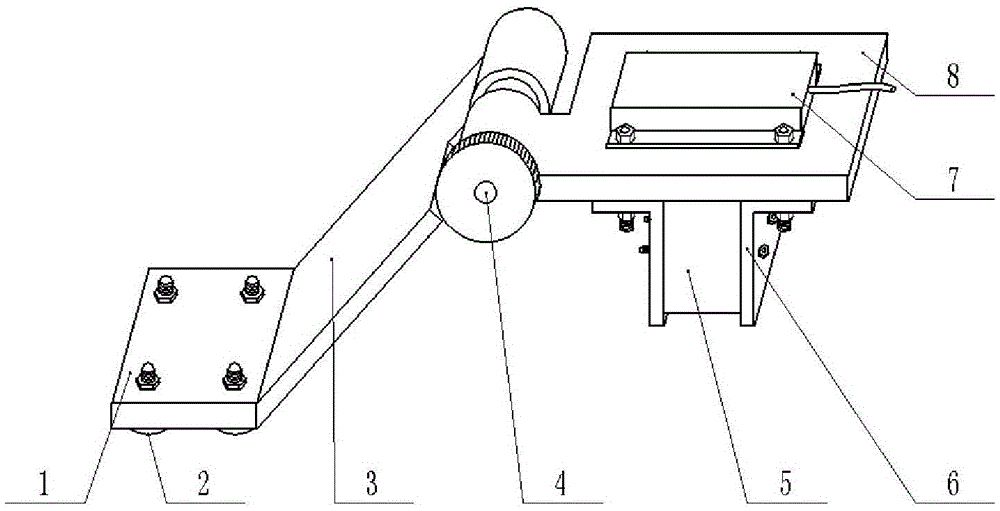

[0034] The specific structure of the mechanical part is as follows: figure 2As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com